Changing Golf Shafts – When I Use a Shaft From a Different Company Do I Use the Same Flex I Currently Play?

Sometimes and then again, sometimes not. Sorry but that’s the truth because there are no standards in the golf industry for how stiff any of the letter flex codes are from company to company. There never have been and never likely will be any sort of flex/stiffness standards in the industry because the vast majority of the various golf equipment companies don’t want that. So the R flex from one company can have the same stiffness as the S flex from another company or even the same stiffness as the A flex from a third company. Not only that, but the same flex of different shaft models within the SAME company is not necessarily going to be the same stiffness.

Sound a little confusing? Or a little bit like that’s not the way it should be?

Actually, it’s fine if each golf club company or shaft company wants to design their shafts different than another company. In doing that, they can express their own beliefs for each of their shafts should be designed. Each company is free to design their shafts and set their stiffness specifications anyway they wish.

What’s messed up is the fact that virtually none of these companies provide golfers with specific information to tell them exactly how stiff their shafts are in comparison to any other shafts. When it comes to flex, golfers are literally kept in the dark and have to adopt a “trial and error” means of determining how stiff this or that shaft is and whether it fits the golfer or not.

Since there are numerous shafts in the industry today that cost $100, $200, $300 and even more, a trial and error approach to shaft selection can get more than a little expensive. What’s the alternative? To put your shaft fitting needs in the hands of a custom Clubmaker who works with defined, empirical stiffness measurement data that can be used to compare the stiffness design of shafts and to explain differences in shaft stiffness to golfers in an understandable manner.

In short, many years ago Wishon Golf saw the need for quantitative shaft stiffness information and created not only a measurement methodology for shaft stiffness, but a software program to allow the many shafts in our data base to be compared in a way that you can definitely compare the full length stiffness design of many different shafts. In 2021 the program was re-written and updated to continue to provide clubmakers and interested parties access to empirical, illustrative depictions of the full length stiffness design of many shafts.

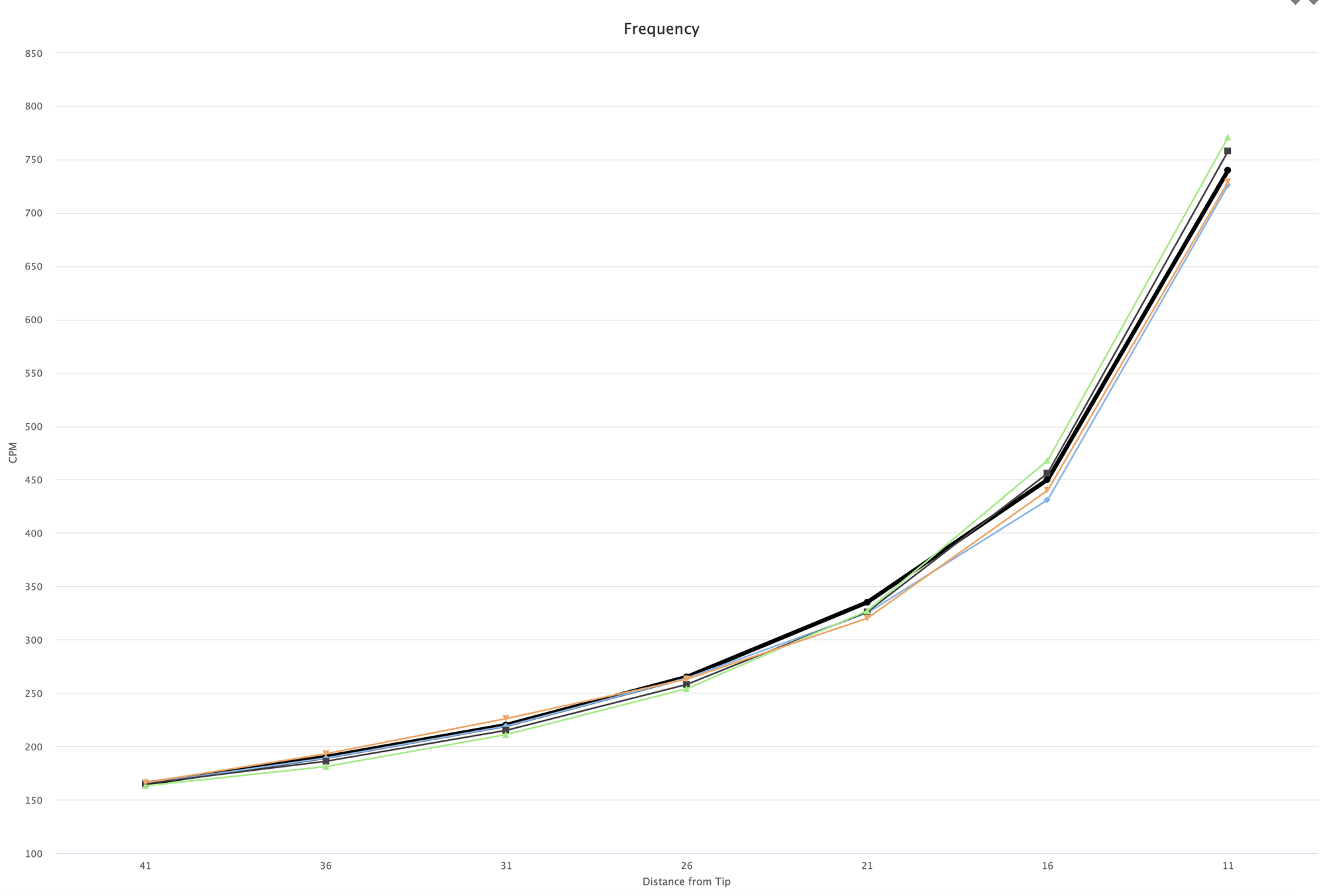

Here’s an example of what the information in the TWGT Bend Profile software looks like and how it works. The following data shows the range in stiffness among a group of typical R-flex shafts.

To translate what you are seeing, if we apply a swing speed rating to each shaft based on its relative stiffness measurements, you are looking at R flex shafts which range dramatically in swing speed rating. And yet all these shafts are marked and sold as R-flex shafts. The same goes on within the entire offering of S flex shafts in the industry as well.

Bottom line? If you want to be fit as accurately as possible for the shafts in your clubs, go get fit by a good, experienced custom Clubmaker.

Tom

Congratulations on technical knowhow and accumulated data. Is your database generally available to the public? If not, it would be of great service to be made available obviously for a fee agreeable to yourselves.

Alan

I assume you are referring to the shaft data in our TWGT Shaft bend Profile software? If so, we do offer that complete software program for sale to anyone who is interested through the GOLFER’S STORE on our website. Software complete costs $129.50 and all updates are free, which we try to do at least once per year with the latest new shafts from all the companies that we can accumulate to add to the data base.

TOM

Thank you for the response. Would you be any more concerned as we leave the irons and move into hybrids, fairway woods, and drivers?

DAN Yes a little more for the driver and woods, but with the hybrids that also depends on how long you make the hybrids. Many of the big companies hybrids are 1.5″ to 2″ longer than an iron of the same loft. So that much longer length allows the shaft to pick up a little more bending action feel that golfers with a very refined sense of feel for the bending of the shaft can detect. But if the hybrids are built to the same length as an iron of the same loft, then no, you can look at them… Read more »

Hi Tom, I am currently going through a process of fitting by Paul Sanders, in Victor,NY,who I was referred to through your site. It has been an eye opening experience for sure. We started with TrackMan numbers to get us into the ball park, and then he put some clubs together for me to try. I am a few months shy of 60 years old, 8 handicapper, swing speed on my 6 iron is in right around 80mph. What we are finding is that I am favoring shafts that are one flex flexier than what the tables suggest. I can… Read more »

Dan I would not be concerned at all with a move into a more flexible iron shaft. Give you a selfish example – I’m 62 and while I have moved up to about an 8 myself from the effects of age and a couple of past ailments, I still have a TrackMan measured 5 iron clubhead speed of 80-82 mph. Last year I changed from my old steel S flex iron shafts to our S2S Black 85 iron shaft in the R FLEX tipped only an additional 1/2″ over normal for the R. That puts these shafts only 1/3 of… Read more »

Hi there, I enjoy reading through your article.

I wanted to write a little comment to support you.

Thank you! Best wishes in this great game!

TOM

Its such as you learn my mind! You seem to grasp so

much about this, like you wrote the e-book in it or something.

I think that you just can do with some percent to force the message home a bit,

but instead of that, that is wonderful blog. A great read.

I’ll certainly be back.

Thank you very much and we’re pleased that you enjoy the information!

TOM

The consistency of manufacture is re-assuring. To someone like me who knows nothing about the manufacture of graphite shafts it is, as you say, impressive. Golfers of my standard don’t deserve it!

Moving of this topic a little, is the same consistency of manufacture true of club heads?

Sandy

SANDY: The absolute best clubhead production factories in the industry all do their production for their golf company customers on the basis of delivering a +/-1 degree tolerance for loft, lie and face angle, and a +/-2 to 3 grams for the finished headweight. From the best head making factories, that really means out of 100 heads, you will see 50 that are dead nuts on the design spec, 35 which are within +/- 1/2 degree and 15 that are between +/-1/2 and 1. For the not as good factories, it jumps higher than that for sure. So what all… Read more »

Thank you for the quick reply. You do a lot of technology development and don’t neglect the legwork (2100 shafts in your database). One point you didn’t quite answer related to the variability of what is nominally the same shaft. for example, I’ve just looked at the TaylorMade site and they give the briefest of information on the Aldila RIP Phenom 60 R shaft (but nothing specific on flex) for their R11S driver. How similar (or different) would you expect samples of that shaft to be in flex, weight, torque etc. Would such differences be of consequence to an average… Read more »

SANDY: Most of the more well known shaft companies like Aldila do a pretty good job of managing the shaft to shaft consistency for their models and flexes. With all shaft companies you do encounter the occasional odd one, but that’s fairly rare, usually on a 1 in 40 or 50 basis – which is darn good considering all that has to be done precisely to keep the shafts tight to tolerances. From all my experience, only when you work with a truly remarkable ball striker, someone of a tour player or top ranked amateur do you need to sort… Read more »

You provide an interesting table of shaft data but i read and am told that there are a lot of quality control issues with shaft manufacture so that what are nominally the same R shafts for a particular model could vary substantially. Assuming that is so. how is your table created – from the manufacturers’ specs?

How do you ensure the shafts you fit to your clubs are what the label on them says?

Thanks

Sandy

Sandy In 2006 we created our own software program called the TWGT Shaft Bend Profile software. WE also developed our own equipment and methodology for measuring the stiffness of a shaft at 7 different points all along its length from the butt to the tip. At present we have the full length stiffness measurements for more than 2,100 different shafts in the data base of our Bend Profile software program. With this we can select any shaft or groups of shafts to overlay the graph of their stiffness measurements and display their actual stiffness measurements so that we can very… Read more »