PRESENTING THE MOST VERSATILE ADJUSTABLE DRIVER EVER DESIGNED…

Four years in the making, the 719MW is the most advanced moveable weight driver designed by Wishon Golf. The basis for the 719MW can be traced back to an early design in the mid-80s by Tom Wishon and Elmore Just – the founder of Louisville Golf Company: the Cure driver was the first original heel-weighted draw-bias driver ever made in the golf industry. Made from laminated maple, it effectively proved that the centre of gravity on a clubhead can be shifted with the heel weight. And when a golfer contacts the ball in an on-centre shot, this causes a slight rotation on the vertical axis, creating in essence, a tilt on the spin axis of the ball: reducing the amount of fade on a shot.

A later woodhead design in the mid-1990s by Tom Wishon, the AccuCore 50 Driver, would further demonstrate the benefits of heel-weighted drivers, but also most importantly that at least 25-30g was needed in the heel-side to move the COG enough to the point where a centre shot off the face would create a visible draw bias effect on the shot.

Many modern adjustable weight drivers have a maximum of 20g of moveable weight – this is not enough to move the centre of gravity and create a marked difference for the vast majority of golfers with average clubhead speed.

So when Wishon began the design process for the 719 moveable weight driver, it was obvious that it would need to have the ability to move at least 30g of additional weight around the head to be able to offer regular golfers a chance to be able to see a change in the shape of their shots.

And that’s not an easy task (to say the least).

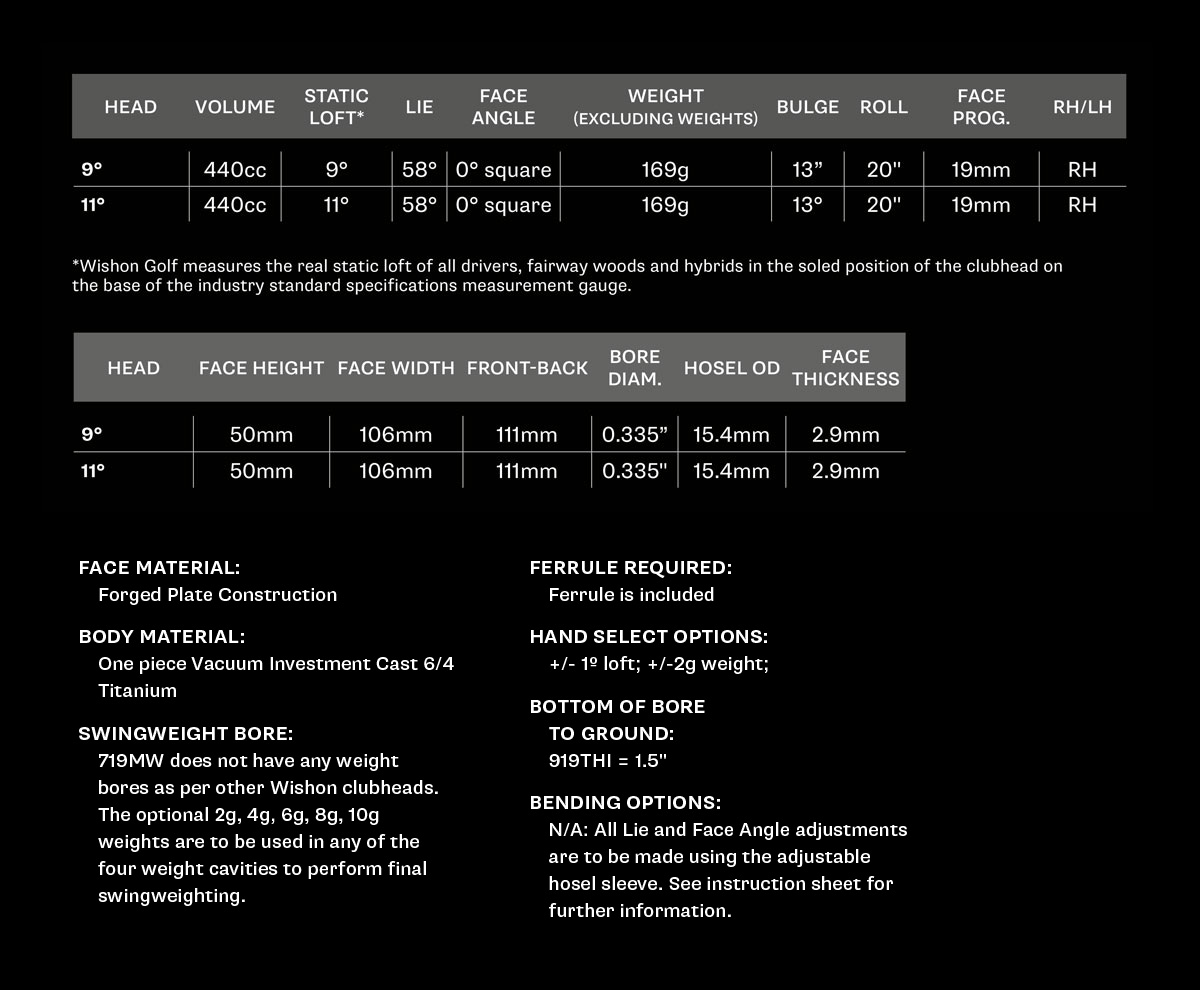

For a 440cc driver, total weight shouldn’t exceed 202-205g in order to be built to a normal range of swingweights, so to take the additional moveable weights, the body of the head had to be in the realm of 172g – an extremely difficult object to achieve.

Wishon was able to engineer the 719MW with the help of one of the very best investment cast titanium foundries in the world, and by varying the wall thickness and removing the entire titanium crown, replacing with lightweight carbon composite, we were able to create the objective design for the 719MW.

The 719MW is the ultimate in advanced adjustable driver technology – offering more versatility and multiple fitting options to clubmakers than any other adjustable driver.

The 719MW features an ultralight carbon composite crown to lighten the head structure and lower CG.

Additionally, the 719MW includes a Custom Hosel Sleeve which enables a wide range in custom lie and face angle specifications and can also be used to offer diffferent lofts when the golfer does not need a custom lie or face angle – only when the driver is held in the square face position at address.

Designed with four separate weight cavity positions, the 719MW has the ability to accept seven different weights – 2g, 4g, 6g, 8g, 10g, 20g, 30g.

+ Place 20g or 30g to either heel or toe position for draw or fade bias OR

+ Place 20g or 30g to either forward or rear position for higher or lower ball flight OR

+ Split 10g or 20g weights in the toe and heel positions to increase head MOI

+ Place other weights in remaining sole cavities to adjust finished weight for fine tuning swingweight/club MOI on a very wide range of finished club length options

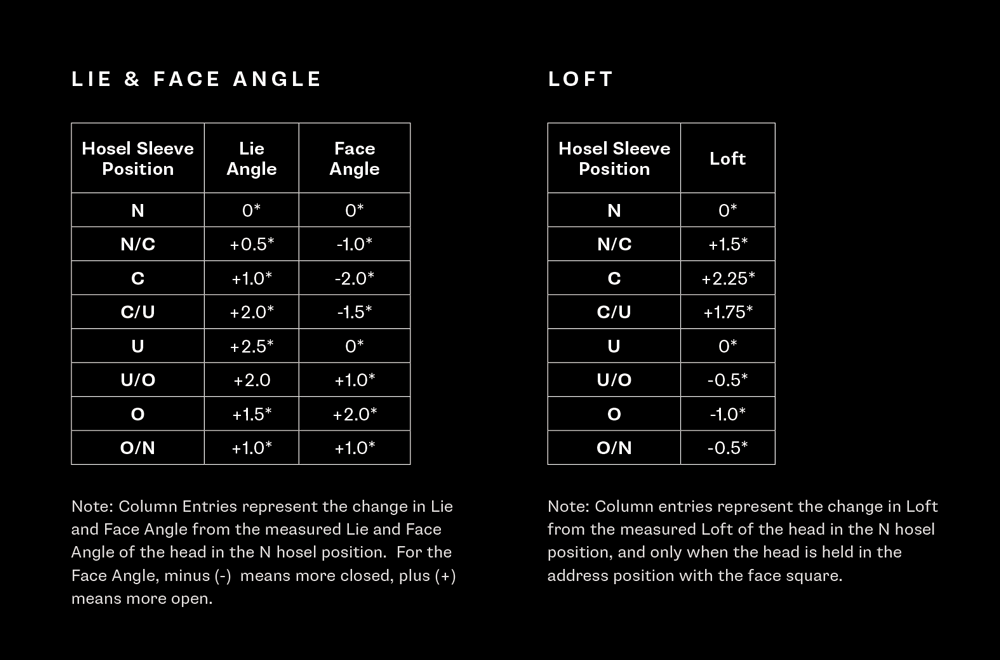

CUSTOM HOSEL SLEEVE

The 719MW’s Custom Hosel Sleeve offers a wide range in custom lie and face angle specifications. The Custom Hosel Sleeve can also be used to offer different lofts when the golfer does not need a custom lie or face angle, but only when the driver is held in the square face position at address.

• With the driver SOLED in the address position, the custom hosel sleeve will allow a change in face angle from 2° closed to 2° open or lie position from 58° to 60.5°.

• By holding the club with the face square to the target in the address position, the hosel sleeve will allow a change in loft of the 9° model from 7.5° to 11°. For the 11° model, by holding the club with the face square to the target in the address position, the hosel sleeve will allow a change in loft from 9.5° to 13°. Full instructions can be found at the link on the right and will also be included with each 719MW driver when purchased.

The following charts reveal the change in the lie, face angle and loft specs for each of the 8 sleeve positions for the 9° and 11° models. The change in lie and face angle is in relation to the measured lie and face angle of each 719MW head, when it is measured traditionally with the hosel sleeve in the N position.

(Hosel sleeve designations: N= Neutral; C=Closed; U=Upright; O=Open)

- All 719MW Drivers are supplied with a wrench, custom hosel adaptor and ferrule included. All components are also available to purchase individually.

- All weight pieces available and sold separately in: 2g, 4g, 6g, 8g, 10g, 20g, 30g.

- Also available is the Wishon 360 Grip, made for matching with the 719MW.

To ensure the longevity and proper function of the Wishon 719MW driver, it’s important to handle the head weights with care during installation.

Important Installation Guidelines for Head Weights:

- 2g Weight: Due to the soft material construction of the 2g weight, this weight only needs to be screwed in until the top of bolt and the weight sit flush inside the cavity and does not need further tightening.

- Do Not Torque Down Lighter Weights: Specifically, the 4g, 6g, 8g, and 10g weights should be installed by hand-tightening only. Applying additional torque can strip the threads or cause other damage.

- Handling Heavier Weights (20g and 30g): While the 20g and 30g weights are heavier and may seem to require more secure fastening, it’s still recommended to hand-tighten these weights. If additional security is necessary, use a thread lock to secure them without over-tightening.

Always ensure that weights are snug but not overly tight. Over-tightening can lead to thread damage, compromising the integrity of the clubhead.

© COPYRIGHT 2025 WISHON GOLF

Hi Tom, many thanks for your recommendation to text David Edwards for expressing my interest in a left hand version of the 719MW driver. Highly appreciated his detailed feedback to my request! David mentioned the difficulty of this model being removed from the conforming list. Could you please elaborate a little bit on this characteristic time and why the 719MW finally failed although I bet you took plenty of days testing this before submitting it for the conforming test? I saw Krank Golf’s Fire X and XX drivers are facing the same issue. So the 919 remains the conforming driver… Read more »

Michael I’ll try to outline what all happened with the original 719 driver that caused the R&A to put it on the non conforming list. I don’t think that I have ever been so upset about something in my entire career, and even more frustrated that the R&A and the USGA refused to even consider investigating my own testing that countered what they said. The 719 is the first driver ever designed that has the capability to allow the addition of such a large amount of weight to the head. I designed the head this way to enable custom clubmakers… Read more »

Is there a weight at which the body of the driver may be at risk for damage? Say I make a very short driver that necessitates a 220g head, I assume the 169g body can carry that without issue, is that correct?

KYLE The 719 was tested with more than 60g added to the head and there were no issues with any sort of durability. We didn’t test it with more weight added than that because it is highly unlikely that golfers would ever need to have the head be as much as 220g for its head weight. But if there ever were a situation where more mass than that were needed for the golfer (very short length but with a heavy feeling head) I am sure it would be ok. The only place where there could be a problem with hitting… Read more »

Tom, it’s really unbelievable how unfair R&A/USGA is treating you. Thus, I fully understand your frustration as they did nothing else than robbing you. Not only it’s ridiculous that they use a testing method whoch is not able to measure the COR correctly. Even more, it’s simply a fraud that other drivers are not tested under the same conditions with a much lighter head. Not sure if USGA and R&A benefit from making things easier for the Big Brands, but the whole sounds fishy. I really don’t want to imagine all the R&D costs put at risk by their stubborn… Read more »

MICHAEL Thank you for your support and for wading through that long response I posted. Your question obviously got me going on this topic again! Based on my long years of experience, the USGA’s stance comes from the two guys who headed up their technical department between the 80s and 00s. Both developed the attitude that the golf companies could not be trusted and were always out to “put one over on the USGA”. Much of this came from when PING actually sued the USGA in the late 80s over the matter of their Eye2 irons being declared non conforming… Read more »

Came across your drivers through some preliminary research. Looking for the flattest head off the assembly line before sleeve adjustment. I struggle with a driver hook. Got my irons bent to 3 flat and hitting great. What is the flattest you make your heads before adjustment, and can they be ordered directly?

Justin Our model 919 drivers are made with a special CP4 grade titanium hosel to enable them to be bent +/-4* in any direction to custom fit the lie and face angle for golfers’ needs. CP4 is a non alloyed pure grade of titanium that has a much greater ductility than the alloyed titanium materials used to make the body and face of a driver. So that is how it is able to be bent. However, it takes a special loft and lie bending machine to secure the head for bending the hosel. Normal LL machines for bending irons won’t… Read more »

Tom, I’m really interested in the 719MW driver. However, I’m a lefty. Is is now or will it be available for left handers?

STEVE

That’s a decision that the high ups at Diamond Golf make these days, not me! Because they have all the access to the numbers from sales so they can see if it seems like there could be enough interest to merit the investment in the tooling to do the 719 in LH. So far from what I have heard, probably not, I am sorry to say. But you are free to ask davidedwards@diamondgolf.co.uk and see what he has to say.

TOM

Hey Tom, a question about the GRT face on the 719. A lot of amateurs, myself included, have a negative angle of attack with the driver, which is not ideal, especially at slower swing speeds. Does the GRT face found on Wishon drivers offer better launch angle on strikes lower on the club face compared to most OEM designs? I am planning on building an 11* 719 set to the 13* setting and a playing length of 43.75” with a Newton 4 dot shaft to hopefully build a more forgiving “mini-driver” (I know the 719 head is much larger than… Read more »

DJ The GRT face has evolved over the years to be a 20″ roll radius from top to bottom. Most every other driver is made with a usual 12″ roll radius. So that means the GRT will have about 1-1.5* more loft on the bottom of the face than the bottom of the face will have on a 12″ roll driver. That’s noticeable for sure, but against a definite downward angle of attack, it is not a huge difference. Golfers with a definite negative angle of attack with the driver who note that they hit the driver lower than desired… Read more »

Tom, you’re spot on. My 719 is dialed in with adapter on (c), length is 44”on Black 65g, 30g in heel, 4g in back and 2g in both toe and front. Almost every swing results in a near straight flight, little power fade is gone and after fridays round impact zone is center with some higher or lower on the face. Gaining some 10 yards but love the muted click off the face is for me very rewarding. I have hit many OEM max drivers that that don’t close the face angle the way my 719 does. Thanks for such… Read more »

GARY

That’s great to hear!!! There is nothing better than when I get a chance to offer a suggestion for a little help and it all works out well!!

TOM

Tom, I am having a bit of a problem setting the adapter on your 719 driver. I play sl irons so my downswing is a bit on the steeper side and my misses are over the top with too much slice. I have 30g weight in heel and 2g in the other 3 weight ports. It’s in your Black 65 reg at 44.5” I am hovering the head and squaring the face. Hope you can suggest a couple of settings for me to loose the slice. Thanks

GARY The most significant reduction of any slice has to rely on a change of the FACE ANGLE of the driver. Putting weight in the heel of a driver will have some effect but not nearly as much as a change in the face angle. This is because a face angle change brings about a degree for degree reduction of how much the face might be open at impact to generate the slice. Heel weighting moves the center of gravity toward the heel so a center face impact then generates a rotation of the head that causes the angle of… Read more »

hi,

if you replaced the carbon crown with a plastic one, would it make a noticeable difference?

if I cracked the carbon crown or drilled a hole in it and patched it up with some plastic and epoxy or glue, would I see a notable difference in performance? I’m just curious. it would be cool if you could just 3d print a crown out of plastic.

Alan I have to say this is one of the more unusual questions that I have been asked. I’m not sure why you would want to replace a carbon fiber crown piece with a plastic one. The two would be fairly close in density so the weight of the head would not be affected much. And there are many different plastics which vary in strength so you would not want to use a plastic that was much lower in strength or modulus (stiffness) since the top of a driver head does flex a bit during impact. And it would be… Read more »

I thought printing in plastic would be cheaper, I didn’t consider mass production. Oops. For whatever reason I just don’t like the idea of carbon fiber and resin, and doesn’t seem ideal. Seems overrated,, but I really don’t know anything. You could 3 d print all sorts of patterns or vary thickness for testing to change how it flexes or adjust acoustics. It might be interesting to design a crown that could be popped off and on, and weights could be placed in that way instead of from underneath like everyone else. Could be more precise with rat glue. Weights… Read more »

ALAN Thanks for taking the time to clarify your thought about using plastic for the crown instead of carbon fiber. The carbon fiber used to make crown plates on metal woods is not expensive at all and in fact is only a few cents more than if you injection molded a plastic piece for the job. For one, the crown plate uses only a very small amount of carbon fiber. And two, the strength requirement for the crown plate is not all that much so that too factors into the lower cost of the carbon fiber. Another reason is psychological… Read more »

Hey Tom question on spin reduction. How much would the spin rate change if you went from 30 grams in the back weight port and moved it to the front? Along that line, how is the spin reduced? Is it because the delivered loft gets reduced from the weight being forward and that produces less spin? I’ve never really understood how weight location on a head influences spin and launch.

Kourt I can definitely help you understand how weight movement forward and back can influence launch angle and spin. It comes about from the weight position’s effect on the center of gravity of the head, and then how that CG position affects the forward bending of the shaft to influence the dynamic loft of the head at impact. When we start the downswing with a wrist cock angle between the arms and the shaft, before we begin to unhinge the wrist cock angle and release the club, the arms/hands and the clubhead are all moving at the same speed. But… Read more »

Hey Tom,

Looking to go old school with a 135g steel shaft in 719mw Driver (mainly for more control). Final length possibly at 43″-43.5″ inches. I have a swing speed in excess of 115mph with a standard graphite 70g X flex shaft. I’m intrigued with all the weight options of the 719mw to make it work and dial it in… Can you recommend a setup that would work with the weights or offer any opinions with this project. I heard a couple tour players are actually going back to steel in their woods but still very rare. Thank you

JOHN When it comes to what I will call “experimental fitting”, I feel the best way to go is to go to the extreme in what you think might help what you want to cure, and then you back down from there to find the proper final point. So if you go with a heavy shaft in the driver, go with a heavy head weight from the sole weights and see what happens to your tempo, timing, control and consistency especially. You want to find a point where everything feels too heavy and then you begin to back down the… Read more »

Hello again Tom

I read your book,”Common sense clubfitting.” But I cannot find the word “smashfactor” I believe smashfactor is one of the most importend subject in clubfitting. Can you describe what smashfactor and its impact on the five specification on the game improvement fitting factors?

Lasse Smash factor is the ball speed divided by the clubhead speed. So if you have a ball speed of 150mph with a clubhead speed of 100mph, the smash factor is 1.5. If the launch monitor reading the clubhead and ball speeds is accurate, smash factor can tell you whether the clubhead you are playing has a high COR or not. If your driver head were actually a 0.830COR, the maximum smash factor possible would be 1.5. ANything under that indicates either that you hit the shot off center OR, the head (driver) has a COR lower than 0.830 if… Read more »

Greetings Mr. Wishon.

I love you driver and recently bought a set of same length irons EQ1’s. However 1 of your weights at the toe of your driver keeps falling out. Is this a common problem or what can I do to fix it?

Jason

It sounds like the weight plug in the toe end of the head has not been epoxied into the weight bore, with the medallion epoxied over the top of that. I thought that the little information sheet that comes with every head explaining the use of the weight bores says to epoxy the weights into the weight bores and also says to use d little dab of epoxy between the medallion and its cavity surface.

TOM

Tom,

You are great. Thank you for replying, I’ll try that. Again, your clubs are great.

Hi Tom, so when the 719MW driver becomes available you are saying it’s 440cc not the stated 460cc in catalog. I prefer smaller heads. I have owned your 919 white model. Guessing it’s a bit smaller than that one, maybe like some companies call Tour size. I hope smaller is better and hope they are available this year!

Hi Tom, I’ve been a user of your club designs since the Golfsmith days, always the best tech and the best value. Sorry if my question is a repeat, I did not see this question in the thread.

What is the max MOI of the 719MW when optimized for MOI, assuming a finished head weight of ~205 gms?

DOUG With a 10g weight in each of the weight cavities of heel, toe and rear on the sole, the MOI will increase to over 5000 g-cm2. The reason it isn’t higher than that, which is still pretty high, is because to be able to make the body of the 719 be no heavier than 170g with no weights installed, we had to make the body of the head a little smaller than 440cc. But that was another one of the benefits of being able to install a lot of weight in the sole to be able to push the… Read more »

Hi, Nice to see your new driver head, I’m still using the 919THI. I notice on the new 719MW specs there is no GRT like on the 919. Is there a reason why you didn’t go with the GRT face. Thanks

WALTER

It must have been an oversight in the layout of the page for the 719 because for sure, the 719 is designed with the same GRT vertical roll radius as the 919 and every other driver and wood and hybrid I have designed over the past 15+ years or so.

TOM

Tom I’m really impressed with 719MW. The head is the perfect shape to my eye and looks great in the setup position. The distance is similar or better compared to my 919THI. The weighting system is terrific. My questions have to do with the Wishon adapter wrench and adapter wrenches in general. Is the Wishon wrench supposed to click when tightened to specs? If not how do you know when the head is properly secured? I have a fear of overn -tightening and possibly stripping the adapter threads. Are all golf wrenches interchangeable? I really be interested in hearing your… Read more »

DAVE

Yes the wrench is set up to click when the proper torque is applied to the rotation of the screw. I think pretty much all the clubs with adjustable hosel sleeves are set up with wrenches to do this. And in most cases, yes, the screw head for most all of the adj hosel locking screws is the same, a TORX #4 I think, spoken off the top of my head with no stopping to go look that up!! HA!

TOM

Hi Tom,

Is the 719MW conforming for competition if one chooses to use no weights and any of the weight cavities?

NATHAN Yes for sure, there are no restrictions in the rules for using weight cavities on the 719MW driver. At its lightest weight with no weights, the head weighs 169-170. So at the much lighter range of weight up to say, 185-190g it could be a good head for juniors or for people who know they play better with a much lighter driver head weight than what is normal in the industry. But it also can be weighted so that a player that wants/needs a very short driver such as 41-42″ for ultimate control and accuracy, it can be built… Read more »

Tom, I thought there were legal restrictions on faces COR? What’s with the 10,000g faces? What have they done or is it a new marketing tool? The way they advertise them the whole driver face is a sweet spot! I thought you can have a minimum thinnest?

GARY You’ve got a little misinformation going that I need to clear up first before going into an explanation to help you. The 10,000 number you have heard bandied about in claims for performance of drivers is the combination of TWO Moments of Inertia (MOI) in the head added together. The MOIs have nothing to do with the COR. COR is the Coefficient of Restitution and is a measurement of the “springiness” of the face. The higher the COR of the face, the more the face flexes inward when the head hits the ball, so the more energy is transferred… Read more »

Tom,

All things being equal, how much higher would this driver launch the ball (with a 30-gram weight in the rear position) vs. an identical loft 919THI driver.

Thanks!

RAY All things being equal, and for sure there would be a LOT of variables involved to equalize (!!) the 719 with a 30g weight in the center rear cavity would launch the ball about 1.5* higher than a similar impact from a similar loft 919. Biggest variable is the point of release of the golfer. Rear or forward weighting can only act to influence launch angle for players with a later to very late unhinging of the wrist cock angle. All other golfers with early to midway releases won’t see any change in launch angle from forward or rear… Read more »

Hello Tom

I usually FLO every shaft in the position six o’clock. That means the flo is pointed down according to the center of gravity of the head. The idea is that the shaft will allways bending down and foreward according to the center of gravity of the head, not the face of the clubhead. I understand that this is a subject of discussion and I am not shure. Can you help me understanding which way to assembley the clubhead according to FLO of the shaft?

LASSE Almost all of the clubmakers I know who FLO the shafts they work with will install the shaft so the FLO plane is aimed in the direction of the target. This is so when the shaft begins its forward bending after the unhinging of the wrist cock angle, the forward bending is straight and cannot cause the head to move up or down to create more of a chance of an off center toe or heel side hit. Some of the clubmakers take this a step farther – they note the golfer’ swing path and they orient the FLO… Read more »

Tom, question about adding weights to the head of the 719. Is their a limit as to the weights you can add to the head. e.g. a 30gm in the rear and a 20 in the heel and 5gm in the front and toe ports.

GEOFF The 719 head with no weights has a spec weight of 170g. If you added 55g to that, the head at 225g would likely be too head heavy to be functional as a golf club. The swingweight would be too high. How much head weight to use is first and foremost dictated by what swing weight feels best to you, not too head heavy and not too head light, based on the length, the shaft weight, the grip weight and what YOU as a player perceive to be too head heavy or too head light. For example, if you… Read more »

Hello Tom

Just saw your video on the new driver 719MV.

A question, when you put 30 gram to either toe or heel and then place a 2 gram opposite, i agree the will change the center of gravity, but how about smashfactor, will smashfactor be 1,50 at the center of gravity or the center of the face?

Lasse The smash factor would be at its highest for impacts in the center of the face. This is because the center of the face is where the highest amount of face flexing can happen. With EVERY driver that is fully hollow with no support behind the face, any time you hit the ball off center the face is not able to flex as much as the impact on center. Now with a good variable thickness face, which the 719 does have, impacts that are as much as 1/2″ to 3/4″ off center still can have a 1.50 smash factor… Read more »

Message to Paul : interesting you should bring up shafts and the 719. I’m in the process of working with my fitter in n j ( Tim mossel ) the first one I tried was the Wishon white wood 60 gram . I hit the ball well ( as I said in my remarked below) But I felt some stiffness at times on impact. My 919 driver has a 45 gram shaft .no stiffness but not as long or high as 719. So Tim mossel is going to try to put a lighter shaft in the 719 . I’m head… Read more »

i have measured torgue on shafts today and I measure ironshafts one inch from the butt end and at the tip of the uncut length of the shaft. One pund and one foot. My measured values are much higher then your values of the same iron svhaft. Howe to you measure your shaft?

I would like to reply to newest letter from Paul. Paul I’m 70 years old and my swing speed is not what it once was. Yet, I’m hitting the 719 further and higher than my 919. Now I will say the face is set “ neutral” ( which allows me to concentrate on the height of my ball) I have 30 grams of weight in the rear of the club. If you can set at neutral ( no draw or fade bias) it’s a longer driver then 919. By the way my 919 driver is 13.5 loft.

Tom and Ken, I now own both a 719MW and a 919THI driver. My search now shifts to the best shaft for a target length of 44″. My question is: what are the rules for tip trimming when extra mass is added to a driver head? I have read in another post about the “1:2 ratio rule” when a club is not built to standard length. I need guidelines to adjust tip trimming when mass is added to a clubhead. Thanks to Ken for the additional input. Very surprising your 919 is 13.5 degrees in loft given the higher launch… Read more »

PAUL There are no “rules” per se when you add mass to the 719 head for the tip trimming of the shaft. The clubmaker has to use his best judgment for whether to increase the tip trim when increasing the swingweight (or MOI) of the driver based on what will perform the best and FEEL THE BEST to the golfer in the finished club. These things can be two separate elements in a fitting to assess whether a normal tip trim of a shaft would end up too soft or too stiff or just right for the golfer, AND THEN,… Read more »