IRONS

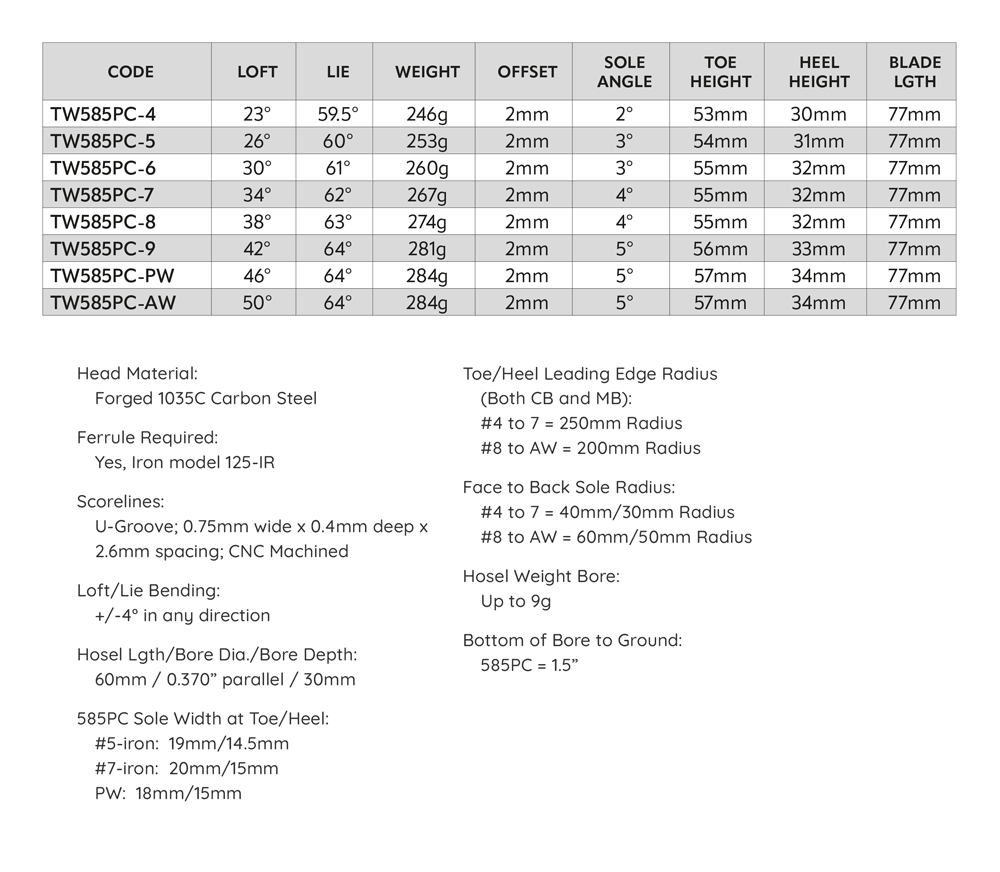

The 585PC (Progressive Cavity) irons are the next generation of true forged carbon steel irons from Wishon Golf. As the first company to use CNC machining to create the entire back design of a forged iron with the 560MC in 2007, Wishon Golf has expanded on this with the 585PC, using a unique progressive design across the set.

- 585PC combine a progressive cavity back design on the #4 to 7 with a progressive muscleback design on the #8 to AW, with each iron’s back design fully created by CNC machining to achieve a precise position of the CG in each iron.

- The 585PC cavity back #4 to 7 iron demonstrate a progression of the major rear mass below the back cavity from lowest on the #4 iron, slightly higher with each iron to the #7 iron. This keeps the CG lower on the low loft irons to enhance launch angle and spin.

- The 585PC muscleback #8 to AW present a gradual vertical rise in the mass of the muscleback to slightly raise the CG to optimize shot height as loft increases to prevent ballooning of the shot.

- The 585PC are first 5-step forged from soft 1035C carbon steel before each back design is fully created by CNC machining, to reduce internal voids which results in superior impact feel.

- The U-groove scorelines of the 585PC are individually CNC machined under 2010 USGA/R&A guidelines and are fully conforming to the Rules of Golf.

© COPYRIGHT 2025 WISHON GOLF

Do you have info on the specs of the Harvey Penick Plus irons that Tom Wishon designed for him?

Marcus Wow, your question made me dig pretty deep into my collection of old things (!!) but I did have a copy of the 1997 Penick catalog that has the Penick Plus irons in it. I have to say thanks for allowing me to bring back the memories of working on the Penick line, and of course, of having so many wonderful moments being with Harvey before he passed. As I head into sharing the specs, I can’t believe that the Penick Plus irons included a 1 and 2 iron! Irons that are completely gone today thanks to how low… Read more »

I purchased the 585PC irons about a month ago and have never been more accurate. I play to about a 10 hc, but my distance has decreased dramatically and I am hitting all of them much higher than ever before. My fitter, Patriot Golf, put F2 Recoil Dart shafts on them. I have played with these shafts previously and really like them. I am at a loss as to how to get my distance back. Any thoughts?

BOBBY Probably because your previous irons were made with lower lofts per each head number than are the 585s. I designed the 585s to be a pure players club, for golfers with a little higher clubhead speeds than average golfers who tend to opt for game improvement and super game improvement irons. The 585 #5 iron loft for example, is 26*, which is about where all the better players’ forged carbon steel irons are designed for loft. Most game improvement irons over the past decade or so are based on a 5 iron loft of 25, 24, 23 and some… Read more »

Hello Tom, Thanks for your engagement with comments. The factual information and non-marketing spin is greatly appreciated. I am looking to be custom fit properly and I am interested in the 585 PC irons. What’s your advice about choosing between 585PC or the more forgiving and longer distance irons? Do you recommend most golfers go for the 565MC/771CSI? For context, I play off 9 and struggle with distance and accuracy too but don’t want a clubhead that’s large or has a thick top line. Also, might there be new irons/refreshes worth considering? On clubfiiters, I live in the UK and… Read more »

Thomas Personally, I detest marketing spin. If I ask for information, that’s all I want. So I have never tainted anything with regard to equipment questions and never will. That attitude about marketing probably explains why my brand has never gotten very big! Anyway….. Serious golfers really should think about playing what they want to play, but of course within reason based on your ability and how much you want your equipment to cover up for mistakes you make in making swings to play. In other words if you said you are a 16 hdcp and you wanted to play… Read more »

Hi Tom,

Thanks for the detailed reply. Apologies for my initial comment being unclear. What I meant to communicate, was that I appreciate that you do not do marketing or spin. Looking back, I probably should have re-written it or included a / between marketing & spin. Again apologies, I was definititely not criticising you or saying that you do marketing spin (just the opposite). You can also ignore my other identical comment below (there was a technical issue with submitting the comment).

THOMAS

Understood! Although I would say that a little bit more of actual “go see your custom clubmaker to be custom fit” type of marketing would not have hurt!!! HA!!

TOM

Hello Tom, Thanks for your engagement with comments. The factual information and non-marketing spin is greatly appreciated. This is my first time posting so apologies if my questions are in the wrong place. I am looking to be custom fit properly and I am interested in the 585 PC irons. I had enquired about the 575MMC but was told by David Edwards that they had been discontinued in April. What’s your advice about choosing between 585PC or the more forgiving/lomger distance irons? Would you recommend most golfer go for say the 565MC/771 CSI? For context, I play of 9 but… Read more »

Tom I have had 2 sets of TW irons over the last 15 years, presently with the 575 muscle back design. (They look great and I’m quite vain when it comes to golf clubs.) But I’m struggling to hit down to the 4 & 5 irons (used to hit the 4 with a lovely draw on short Par 4s). Now wondering if graphite shafts would help with greater contact-consistency (there are lots of graphite shaft sets advertised on the internet but they don’t seem to mention the tip diameter or whether the shaft is parallel at the tip). And what… Read more »

TONY The biggest thing that causes a golfer to lose the ability to hit the low loft irons is a loss of clubhead speed. Lower lofts like the 4 and 5 iron launch lower to begin with because of the lower loft. To get a lower launch shot to stay in the air long enough to achieve full carry distance requires a higher ball speed AND a higher level of backspin – both which come from a higher clubhead speed. Since you began to see a higher percentage of less satisfying shots with the 4 and 5 iron, I would… Read more »

Tom Thanks for the quick and interesting response; I had thought about a 9-wood to replace the longer irons (my 7-wood is currently the best club in the bag with high flight and maxing-out around 210 yards). My Pro shop says they are not always available and has suggested a suitable hybrid. So I may request a test-run. Thanks again, Tony.

TONY Diamond Golf may have some leftover heads from our former 765 wood model and it had a 9 wood in the set makeup. You could call and ask if they have any left over, though they may not. Otherwise, it would be a hybrid as you said. But I do recommend that if you do the hybrid to replace the low loft iron(s), have the hybrid built with the same loft and the same length as the iron you are replacing so you have a better chance of the distance fitting right in with the irons to avoid an… Read more »

Hi Tom ,

I hope you’re well,

The 585 PC are fatastic, I hav them in my workshop in France.

Will you do the single length version, that would be the perfect irons

Thank you

JIMMY Thanks so much for your very kind words about the 585 irons!! We appreciate that very much! Now I have to be honest and tell you that it is highly unlikely that I would design a single length iron with the heads made like the 585. For one, the cost of forging dies for a set is over ten times more than the cost of investment cast dies to make a cast stainless steel set. The only way to offset that increase in cost is with more sales volume. And that won’t happen with a single length set, since… Read more »

Hello Tom, Im a club professional based in the UK, I have built and played with Wishon clubs since 2005, I’m now on my 2nd set of 555, which you found for me after they were discontinued when I was based in Spain, I love the feel of the 555, but they are now starting to look tired and I have been waiting for something to replace them, and as I get maybe a little more forgiving than a blade can be, I have been impressed by the 585 and the reviews its been getting and wanted your opinion on… Read more »

MARK First off, thanks so very much for your support over the years. I’m smiling while I type this thinking that you have gone through two sets of the 555 blade model!! Thanks so much for liking those so much, that feels good to know that! As you know from looking at the 585s, the 8 to wedges are blades so that part of the set is virtually the same as what you have in terms of CG and performance, though the lofts are very slightly lower on the 585s since the 555s are old enough that it goes back… Read more »

Hey Tom, My current bag is all Wishon, mixing and matching from all the different sets I’ve built at Bill Owen’s shop. 919 D, 950HC 3W, EQ1NX 4W & 7W, EQ1NX 5H and 6H, then 550m 7i-PW, 309HCG GW,SW,LW. I built the used 550s last year as a fun experiment to practice building an MOI matched set, and it worked out really well. I have however noticed my consistency drops of sharply after the 8-PW in the blades. I can hit the 8i flush 9/10 times, however the 7i I hit well maybe 5/10 times. After that, not very well… Read more »

I recently came back to golf from a 12 year lay off. I previously played your 555m irons so opted to go with the 585’s and to keep cost down used the Wishon series 5 shafts from the old clubs in the new heads. I am now looking to match up some wedges but cannot find any information on these old shafts so wondered if you could provide some insight? Are these still deemed up to date or would you recommend something newer? If up to date is there anything on the market that’s similar to put in my wedges?… Read more »

CHRIS The original Series 5 steel iron shafts were similar to the Dynamic Gold in terms of the butt to tip stiffness design but they were lighter than the standard Dynamic Gold by around 15 grams. So I would think in terms of today’s shafts if you can find a 100g raw weight shaft that is designed with a stiffer tip design, that would be as close of a match as you can find for the Series 5. ANy of the steel iron shafts that are marketed for good players with a late release and stiff tip would be similar… Read more »

I am planning to have a new set of irons built soon (just had a 519 SHPR driver built and pick it up in a couple of days). I am currently leaning toward the 585PC’s but may go with the 565MC’s. 70yo and 7 handicap, and reasonably solid ball striker when playing regularly. Builder is suggesting the 771’s but I definitely prefer forged over cast. Any recommendations would be seriously considered and greatly appreciated! Thank you.

Herb Of the two forged iron models, I would tend to lean a little more toward the 565s because they are going to offer better off center hit forgiveness than the 585. 585 has a more shallow cavity and only on the 4 – 7 heads. The 565 is a blank back forging on which we them fully CNC machine the entire back cavity, which is the only way you can make a forging with as deep of a back cavity to boost the MOI as you can achieve in an inv cast deep cavity back iron. So the deep… Read more »

Thank you. I have more questions about a recently built/purchased 519 SHPR. I used a different builder than originally thought. I struggled a bit with it on the range and my first round (Monday 6/24). I felt like I was unable to get any “kick” out of the shaft (a 65 gram regular tipped 1″ to be a fairly stiff reg.). This morning I decided to throw it on a swing weight scale and was shocked to see an incredibly light swing weight (C-1!). I put lead tape on to bring it up to D-! and it feels much better.… Read more »

Herb Your last sentence probably summed up the problem. Sounds like this is a clubmaker who needs a solid lesson in weight feel fitting. WHile there are clubmakers who build clubs to a specific MOI instead of swingweight, and there are clubmakers that also focus on building to a specific balance point, you cannot build clubs and ignore all the ways that clubs can be fit for the head weight feel, whether that be swingweight, MOI or balance point. You have to pick one or else you can end up with what you have, a club with a head that… Read more »

Herb. I have the 771 irons and the feel of them is indistinguishable from a forged feel. Not sure how that can be, but it is. I use Maxfli Tour or Bridgestone RXs balls which both feel ‘soft’ as well.

771 performance is quite something… Give a try before moving on

Have always admired Tom’s (Wishon) club designs. One of my favorite iron sets that I still often play are the 555M’s. I play them in 70 gram steel fiber shafts, Stiff flex and 1.5″ over length. As a tall golfer, 6’5″, they worked well, good thing my clubmaker left out any added hosel weighting as clubs came in at D7, threw in 12 grams butt end weight to play at D5. Gives club better balance and feel and not head heavy. Would like to build a set in the new 585 design. I hope hosel weight can also be left… Read more »

LEE Since you say you have been playing a full set of 555Ms, that means in the 585s you get the benefit of a cavity back which pushes the MOI of the #4, 5, 6, 7 up higher than what it is on the 555M-4, 5, 6, 7. And that should mean a noticeable improvement in off center hits with the 585 lower loft irons. For the 585 8-wedges vs the 555M 8-wedges, it should be quite similar. The spec head weights of the 585 are the same as the 555 so if the irons are made that much longer,… Read more »

Hi Tom,

I’ve been using your 565MC irons for around 8 years and have been thoroughly impressed with their performance. I’m interested in the 585PC irons and was wondering if they’re considered an upgrade from the 565MC model or if they’re specifically designed for lower handicappers.

Additionally, could you please clarify whether your irons are single or multiple forged? I’m also curious about the differences, if any, between irons that are triple or quintuple forged. Thank you for your assistance.

Vasilis Thanks very much for your interest and your questions. I am always happy to help with more information. I would say that the newer 585 forged irons would be for a slightly better player, or rather, for a little bit lower handicap range than the 565s. TO put a number on that, I would recommend the 585s for players who are between scratch and say, 10-12 hdcp because the back cavity on the #4, 5, 6, 7 is not as deep as it is on ALL of the 565s, so that means while the off center hit forgiveness of… Read more »

Hi Tom. I guess like a lot of golfers I’m a bit lost. I’m 67 and playing with a fairly new set of Wilson staff blades (4-PW) with KBS tour stiff shafts having moved on from a set of Titleist 716MB’s. The Wilson’s dont seem to have consistent gapping of the irons and as my 5 goes about the same distance as the 4 (165m) I have left out my 4 iron which I’d like to have in my bag. I do hit the ball reasonably well but I’ve decided to finally have a look at a proper club fitting… Read more »

DAVE I believe that for sure this matter of having two of the irons fly around the same distance would no longer be a problem, especially with Bob doing the work. He’s very experienced and knows what he is doing. Gosh I have been corresponding with him about clubmaking technical matters for a very, very long time so that’s how I know he knows what he is doing. It is very common for standard made irons to end up with two or more adjacent irons having very close to the same loft, especially in the lower number irons in sets… Read more »

Hi Tom, I have a quick question about MOI matching a set of irons if you’d be kind enough to answer. I don’t have an MOI speedmatch machine but was hoping to get the MOI’s close by having them 8g apart with a 0.5” difference in length (is that correct?). My question is if the weights are definitely 8g apart does it matter if a few of the shafts are lighter than others? I was fitted for lighter shafts than my current ones when I attended the Art Of Clubfitting course at Diamond Golf but I just ordered a few… Read more »

Craig The ball park way of MOI matching in a set of irons is to have the lengths change by 3/8″, not 1/2″. As to the headweight, that 8g is just an approximation and would only be accurate IF the shafts AND GRIPS all weighed exactly the same. The way most guys without a Speed Match do it is to make the lengths change by 3/8″ and then make the SWINGWEIGHTS increase by 1/2 a swingweight point as the clubs get shorter. So just to put some numbers to it for example purposes only, the 4 iron could be 38… Read more »

I have 585 PC set from 4 to PW and a 60 LW 309 HCG! What are the reasons to choose the 585 PC AW (50) and 55 SW 309 HCG versus 50 GW and 55 SW 309 HCG?

Martin Very good question you ask! I’m happy to explain the options for your possible wedge match ups in the set makeup. In the 585 irons, the AW is designed to be the SAME EXACT HEAD SHAPE, HEAD PROFILE AND SIZE as the PW. It is also forged from the same carbon steel as the PW so when you play the 585 PW and AW, you are in essence looking down at the same wedge but of course the AW has more loft with the same 5* bounce as the PW. The 309 50* wedge has 8* bounce with a… Read more »

Hi Tom

I have been using your 757 mmc 6to pw with 5/4i in 565mc but am considering get 585 in 5/4i.I absolutely think my 575 are purest iron I have ever hit. HCP +1fron Ireland my club maker is Jim Byrne top club man. Keep soldiering on Tom.

Robert Barry

ROBERT Thanks very much for your kind words of support for what we do in our work. I do believe that ever since we changed from the old usual 4 step forging process to add a 5th forging step in 2003, the impact feel of our forged iron models has been really superb. The 5th step packs the steel a little more densely in the die which reduces the number of tiny little “holes” in the grain structure of the steel. And that we believe reduces internal vibrations from impact so the feel up the shaft to the hands is… Read more »

I much appreciate your reply Tom.

I picked this clubhead out to test after a club fitting because I love how the blade looks. I have been using an 8i demo built for me and want to go ahead with buying a full set. However, after some research I discovered what the “PC” stands for and that clubs 4-7i are cavity backs. Should I ask for a demo 5i to try next before moving forward with the full sale? I am coming from 2008 Callaway X-Tour 22’s and wanted to move on from cavities. The blades are so much more pleasing to my eye and I… Read more »

DOUG Yes, it was always intended to be a progressive cavity to offer a little more forgiveness and a little higher flight in the low lofts, where that sort of help is more needed than when the lofts increase into the short irons. Still, when you talk cavity back in a forging like this, you are not talking about as much of an off center hit improvement as you would get in a VERY deep cavity back. If a player truly needs the maximum off center hit forgiveness in an iron but still wants to play a forging, this is… Read more »

I am presently testing a 585PC 7 iron and experiencing significantly more forgiveness than expected- exactly what I was hoping for. However, I was wondering what performance difference (if any) there is between a constant offset versus a progressive offset iron design.

Thanks.

Ray

RAY I have never wanted to design any forged carbon steel iron with anything but low consistent offset that is aimed at better than avg to very good player. My standard for low offset has been 1.5mm to 2mm over the years. If you make an iron with 0 offset, the eyes tend to see that as the leading edge being in front of the forward wall of the hosel, so I never do a player’s type club with less than 1.5mm offset. TO most, 1.5mm looks like the leading edge is directly in line with the forward wall of… Read more »

Tom, thanks for your reply. My experience using the 585PC and coming from a forged blade set with progressive in my opinion aligns with your thoughts on offset. The 585PC is a great looking iron and the transition from blade to cavity back is second to none. They do remind me of past models of Hogan Apex irons and for me (which I can’t explained) adds to their appeal. I must also add that your 309 HCG wedges are a great wedge to go with the 585PC. Finally, I am curious if you have had any success in identifying a… Read more »

RAY Many thanks for your nice comments about the progression of the back design and blade design on the 585 forged irons! I am very pleased to hear that you like them! As a matter of fact, hoping to not jinx ourselves, I think we have found a steel shaft factory that we like and which is willing to work with us on some new steel iron shafts. I think we have one model all set up, the lightweight one, and in fact today I will be starting the analysis and testing on the good player shaft samples I just… Read more »

I certainly appreciate that it takes some considerable time in order to bring a full new line of steel shafts to market and wish you continued future success.

These irons looks great!

As this is not available in left hand, which model would you recommend instead?

I prefer ones will small offset….

NIDA Thank you very much for your kind comment about the 585 forged irons. I am very sorry that we are unable to offer the 585 irons in left hand. We are a small company and the total sales of left hand would not be enough to cover the much higher cost of the forging dies and the inventory production. I feel bad about that because I do not want to make it seem that we are not doing enough for left hand players. Because the 585 is a forged carbon steel iron, there are no other alternative models in… Read more »

These Irons look great Tom. I have been hitting the 565MC for 7 years now and love them. How would the 585PC irons compare to them and are these much different than the 575 MMC irons?

BILL Thanks very much Bill. Yeah, I had been looking for an “excuse” to do a new forging so we could use the new pearl chrome finish on it! The 585’s kind or rank in between the 565 and 575s in terms of overall size with the 565s being a larger overall head size and the 575s being ever so slightly smaller in overall size. CG position of the 585s is ever so slightly higher than the 575s but hardly enough to notice. I see the 575s as being a more compact forging than the 585s. The main thing in… Read more »

Hello. Is this “Heads-only” ? In that case I would be interested in buying PW – 6 iron. Would that be possible ?

JOHN

Diamond Golf International creates and distributes products made under the Wishon Golf brand as components only. They sell only to custom clubmakers with experience that they certify so as to keep the integrity and quality of the brand as high as possible. If you are a clubmaker and you are interested in purchasing components from Diamond Golf, you are welcome to contact them at sales@wishongolf.com or by phone on (0)1903 726999 to inquire about setting up an account. Thanks very much for your interest,

TOM

Thanks for the reply. I found a local dealer. Went through a fitting ( with another head).Now I’m waiting to see if and when they will arrive . Curious to see them IRL 🙏

Hello, are the 585PC irons available in left hand?

Brian

I am very sorry but no, we just do not have the size of overall demand to justify the much, much higher tooling die expense of forging dies for a left hand model. Forging die costs are over ten times more than the tooling costs of doing an investment cast iron, sad to say. I do wish that were different.

Tom

Had my fitting for a set of 585’s from 4-p and 3 309hcg wedges done yesterday. Being built by arnaud maurin 33golflab in bordeaux france. Can’t wait to get my hands on them. They look fantastic and feel great!

Danny

That is great to hear and I’m excited for you to hit your first shots with the new clubs! You did right by choosing to work with Arnaud . He is a good friend, I correspond with him a lot over golf technical matters, and I know the fit you went through with him will result in clubs that make you pleased! Best wishes in this great game and thanks so much for your support!

TOM

Hi Tom, I’ve been playing your designs pretty much from day one: Penick Professional Tour then EQ1-NX’s. Last year, on a whim, I played a set of old forged Hogan’s and was hooked the first time I hit the 5 pure. I’ve recently acquired my Dad’s old Golfsmith Tour Cavities (Cast, similar to your 550c) and am really enjoying the feedback from them. I wanted to ask your opinion on a new technology that I haven’t seen you use yet: Polymer filled cavities (a’la PXG). This, along with tungsten weighting, seems to be the new rage in iron design. Wondering… Read more »

ART To be honest with you, hollow irons, whether polymer filled or not, are not new at all. I remember one of the first such hollow iron models was an iron designed by Ralph Maltby for The GolfWorks back in 1984. I know this because I worked for Ralph back then and was part of his first test project team for those irons when they were in development. Among the newer generation hollow irons that began to show up around 2018, PXG was not the first to re constitute this type of design. They just jumped on the bandwagon like… Read more »

Hi Tom, just wanted to compliment you on these great new irons. I had the chance to hit them when I attended Daimond Golf’s Art Of Clubfitting course earlier this month and they feel tremendous. Definitely on my want list

Tom, I’ve had a 585PC 7 Iron built @ 37.25″ and I am looking at adding 8 – PW and will continue from the 7 iron length and deduct 3/8″ between clubs and adjust head weights to achieve moi matching. Since the lengths will be longer than using 1/2″ between clubs would it make any sense to increase loft difference between clubs to 5 degrees- 8i (39 degrees), 9i (44 degrees) and PW (49 degrees. Or maybe 4.5 degrees between clubs? Thanks.

RAY

In ANY set of new irons, I would recommend finishing the build so it fits you and your swing and feel characteristics and then go out and hit shots and play with it for a few weeks, taking time while you do that to reflect on distance gaps, shot heights. Then if you notice anything that you feel could be remedied, corrected or enhanced by a loft change, that’s the time to do that ,if necessary. Not before you go out and spend some time with the irons.

TOM