DESIGN FIRSTS

TECHNOLOGY

First Moment of Inertia Matching System for sets of golf clubs

2004 – WISHON GOLF MOI MATCHING SYSTEM

Engineers with a working knowledge of the performance of golf clubs have long known that matching all clubs in the set to their assembled Moment of Inertia (MOI) could be superior to matching all clubs to each other by swingweight. By building all clubs in a golfer’s set to have the same MOI, each club will swing with exactly the same feel and effort from the golfer. Swingweight matching cannot do that, so the golfer has to use a different effort to swing each club. MOI matching is truly a custom fitting parameter because each golfer has a different combination of strength, athletic ability, swing tempo and point of wrist-cock release on the downswing.

MOI matched clubs must be individually fit to each golfer so that the benefit of improved shot consistency will be achieved by each golfer. Real MOI matching has never been pursued by any OEM because their business model is to make standard made golf clubs with the same specifications, including the same swingweight. In developing the golf industry’s first MOI Matching System, TWGT enabled professional custom clubmakers to offer golfers a more superior method of matching swing feel and improving their on-center hit consistency.

With the assistance of Tom’s engineering mentor Art Mittendorf and clubmaking machinery designer Mondher Lattiri, Wishon Golf was able to develop and offer clubmakers the hardware and software to be able to measure and calculate the MOI of any golf club and to determine how to build or alter clubs in a set to all have the same MOI. The first version of Wishon Golf’s MOI Matching System included an electronic pendulum period counter with a software program to accept the four measurements of the length, total weight, balance point and pendulum period to calculate the MOI. (Above image shows the 2004 period counter with screen image of the software).

A few years later Mondher developed the MOI Speed Match machine which eliminated the need for separate measurements of a golf club as well as eliminating the need for a software program to facilitate the assembly of clubs to a specific MOI. Mondher’s Speed Match machine allowed clubmakers to obtain the MOI from one measurement and to immediately reveal the change in MOI when adjustments to the length, weight, balance point of the club were made. (Above image shows the MOI Speed Match machine from golfmechanix.com)

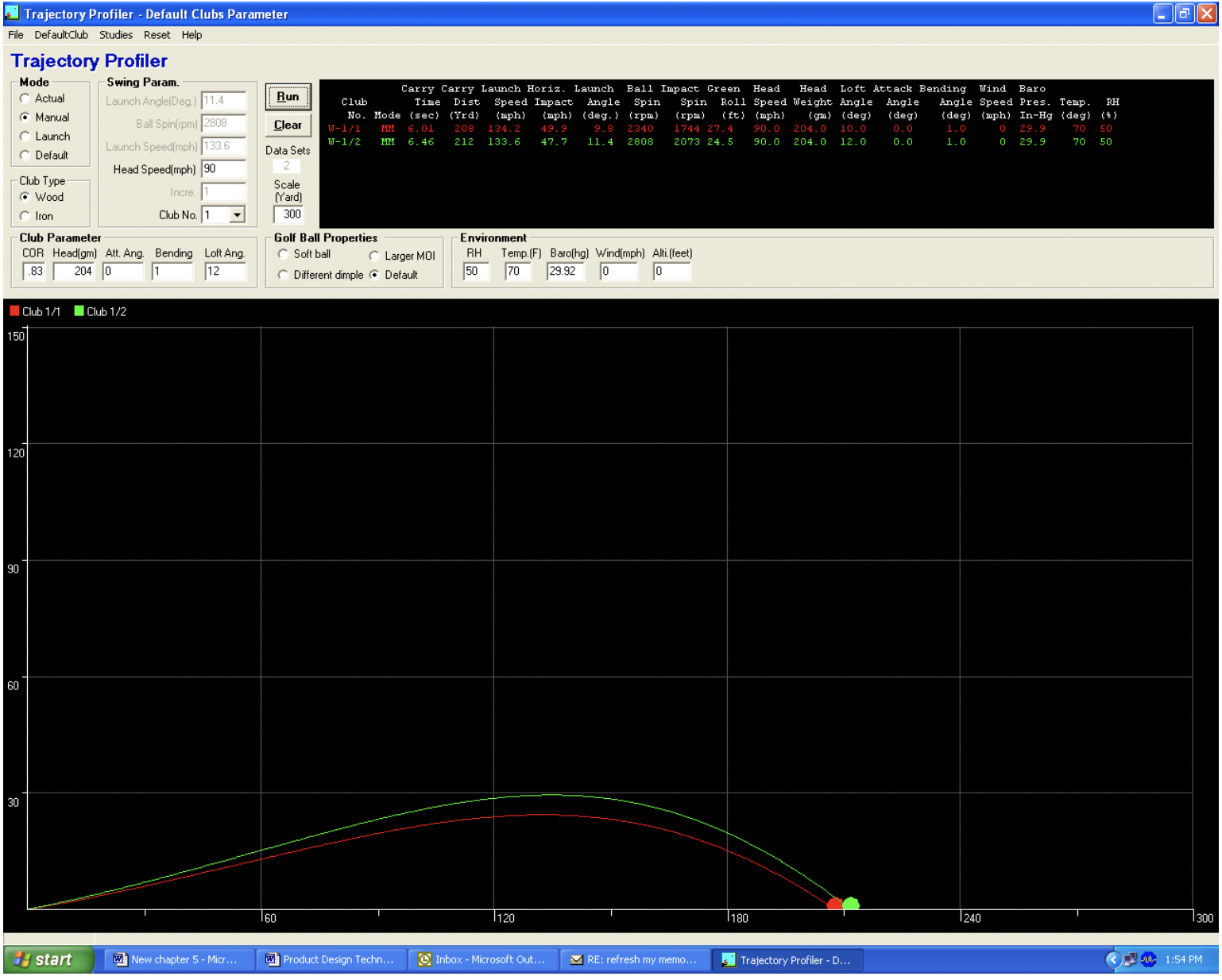

Wishon Golf Trajectory Profiling Software

Wishon Golf’s Trajectory Profile software will predict the complete flight parameters of any shot based on all of the factors that affect the outcome of the shot. The software will allow clubmakers to vary the golfer’s swing speed, angle of attack, amount of shaft bending, clubhead loft/weight/Coefficient of Restitution, and to imput climate conditions of air temperature, humidity, barometric pressure, wind and elevation to predict all shot parameters of launch angle, spin rate, ball speed, trajectory and distance.

The following screen image from the Trajectory Profiling software shows the distance increase possible from an increase of loft from 10* to 12” for a golfer with a 90mph swing speed and level angle of attack using a driver head with a COR of 0.830, weight of 204 grams, a shaft that bends 1* forward at impact, for climate conditions of 70F, 50% humidity, 29.92 barometer reading, at sea level with no wind.

Custom clubmakers use the software to input the golfer’s launch monitor and shot hitting characteristics and come up with the best performance parameters to which the custom set is built.

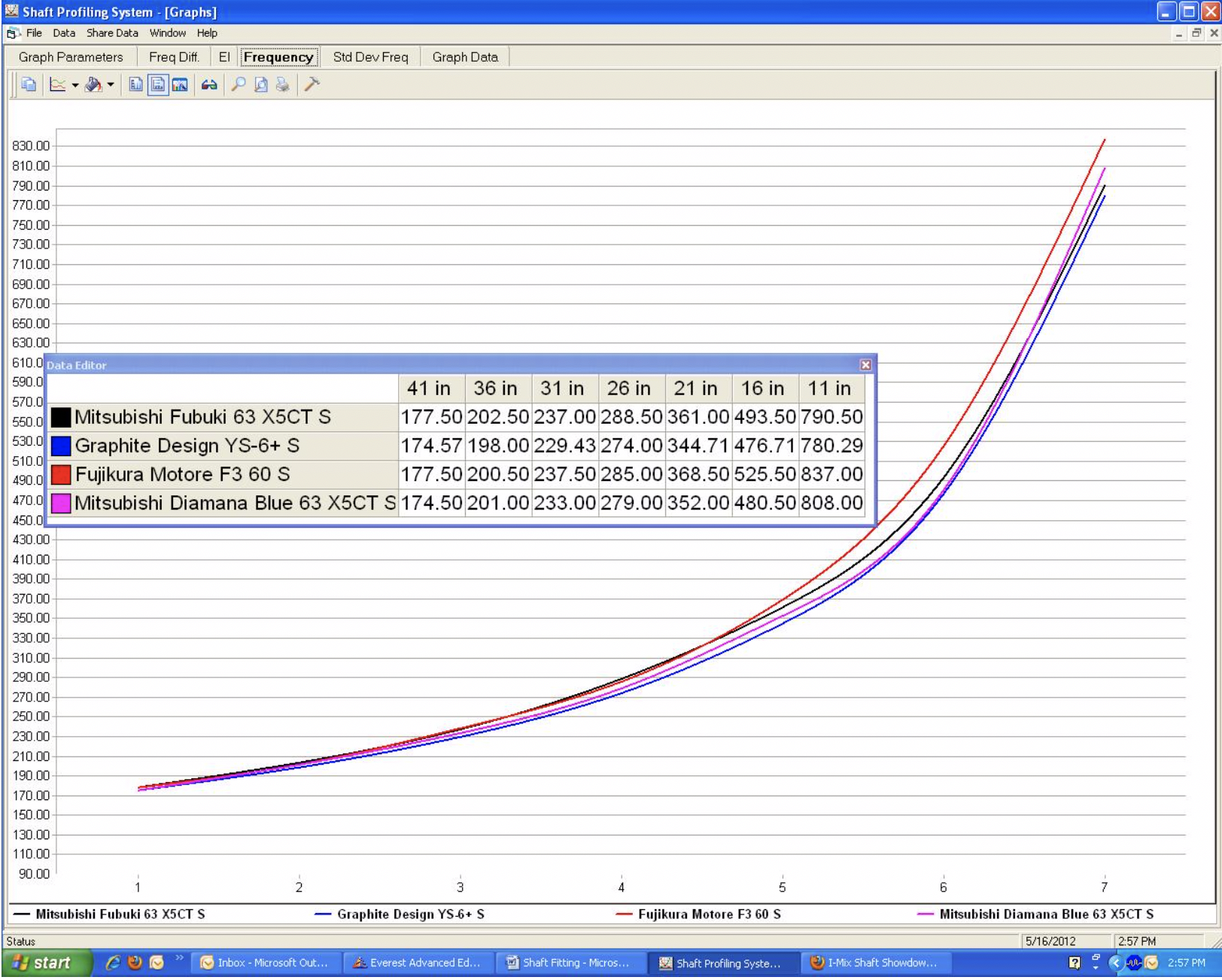

Wishon Golf Shaft Bend Profile Software

There has never been any type of standard method of measurement in the golf industry to enable golfers to know the exact stiffness/flex of their shafts. Shafts have been made with nondescript letter codes such as L, A, R, S and X to “define” their stiffness. Wishon Golf’s Bend Profile System introduces an all new way for custom clubmakers to know exactly the quantitative stiffness differences between shafts.

The following screen image from the Wishon Golf Shaft Bend Profile System illustrates a comparison of the actual stiffness over the entire length of four different shafts. With such a depiction, the clubmaker now knows how much stiffer one shaft is than the other, and knows where on the shaft the stiffness differences exist. With this information clubmakers can fit golfers into a shaft that is better matched to the golfer’s swing speed and swing characteristics.

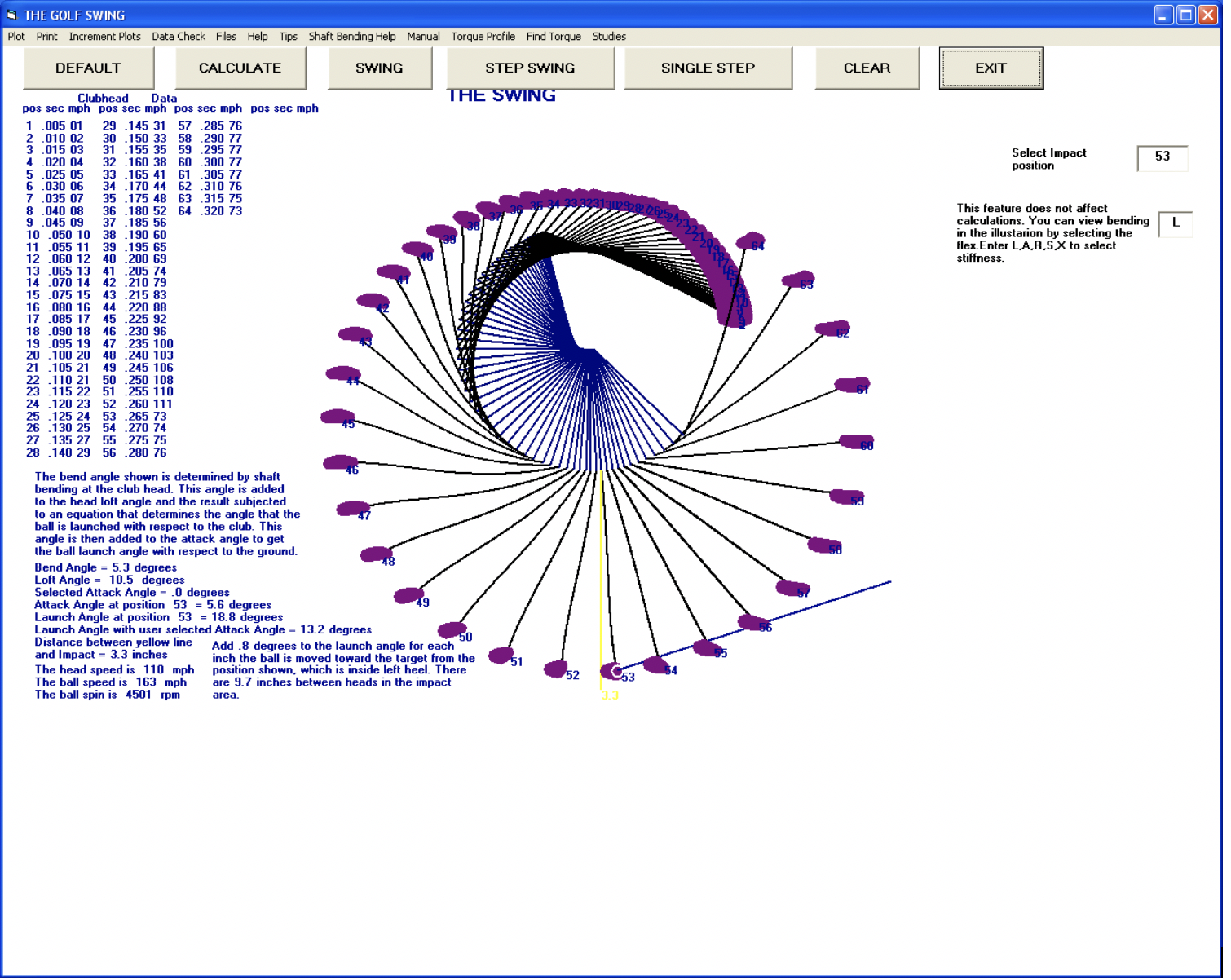

Wishon Golf Virtual Golfer Software

Developed in conjunction with Tom’s engineering mentor Art Mittendorf, the Virtual Golfer software can be one of the most powerful and unique of all Wishon Golf clubfitting analysis programs. With this program the clubmaker can analyze the shot results from measurements taken from any golfer’s swing. In addition, the Virtual Golfer can also allow inputting all key specifications from any golf club to determine how the golfer would hit the club. An earlier version of this software was used to teach Jason Zuback how to change his swing to achieve more distance and win the last two of his 5 consecutive US National Long Drive Championships.

The following screen image shows the Virtual Golfer swinging a club. The vast number of outputs capable with this program are seen on the left side of the screen.