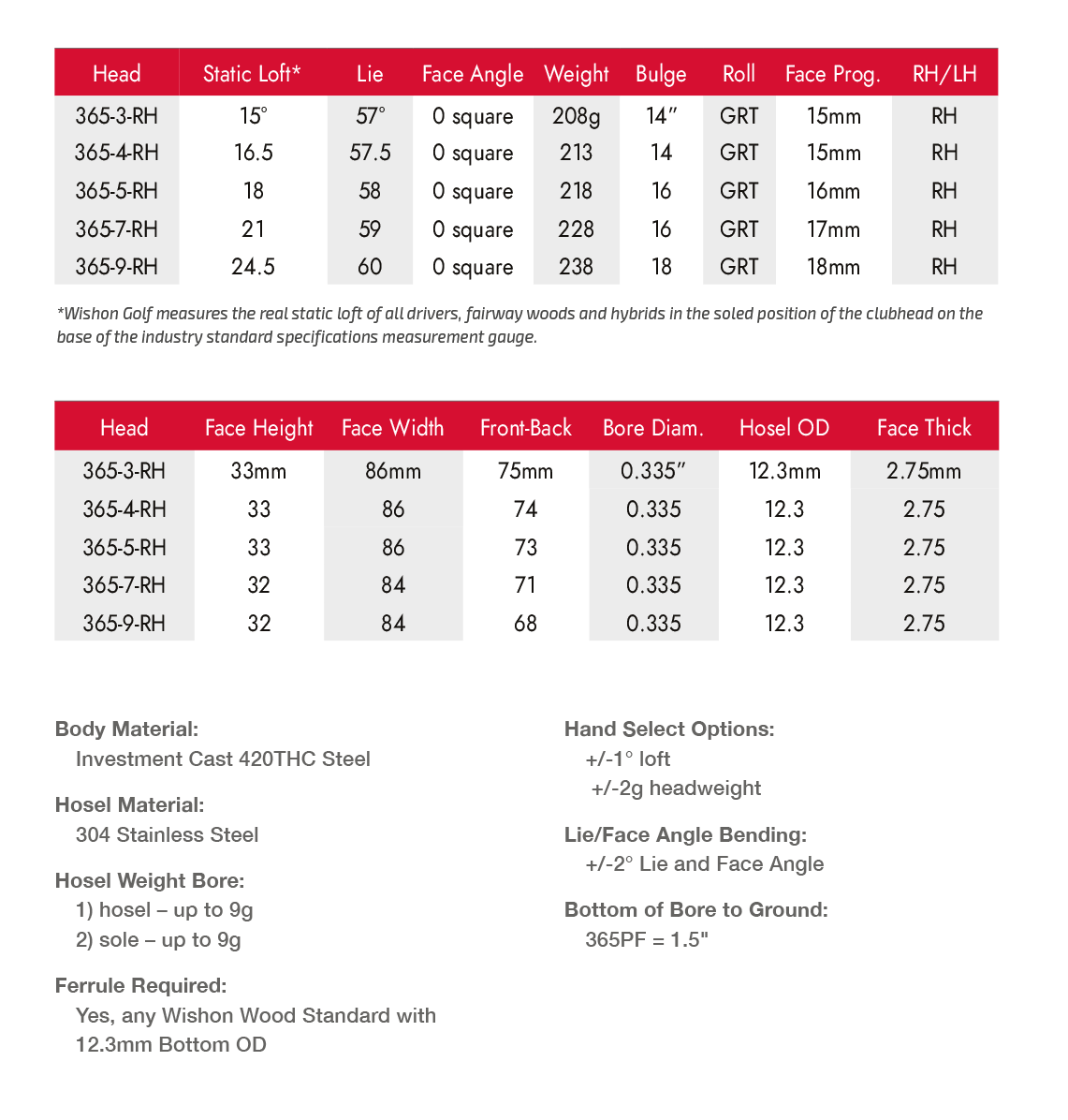

365PF FAIRWAY WOODS

Progressive Fairway Wood Profile Design, Fit and Build as all Fairway Wood or as Combined Fairway and Hybrid Set Makeup

Features:

- The most versatile fairway wood design created. Head size and shape progresses gradually from traditional fairway wood in the #3 and 4 to slightly smaller fairway profile for the #5, to a slightly more narrow fairway to semi-broad hybrid in the #7 and 9

- Twin weight bores allows assembly from traditional fairways to hybrid lengths as desired for the golfer

- The highest smash factor found in a conventional investment cast steel head, achieved through TWGT’s metallurgical experience and knowledge. 365PF offers the best combination of performance and value in a woodhead design

- Bendable hosel allows a range of +/-2° in the lie and the face angle. Hand Select for loft offers +/-1° options for each head model from its designed loft spec.

- Available in RH in #3(15°), #4(16.5°), #5(18°), #7(21°) and #9(24.5°)

© COPYRIGHT 2025 WISHON GOLF

Looking for a nine wood and a six hydrid

JIM Where I am doing my work for the Wishon brand, I am several thousand miles away from Diamond GOlf’s inventory so I do not know if they still have any of the 775-6 hybrid heads or the 365-9 wood heads around their warehouse. Both these models are in the process of being closed out, discontinued, to make room for new models that will debut in the spring. The new models will not include a 6 hybrid or 9 wood (unfortunately in my book) because in all honesty, very few clubmakers ordered a 6h or 9w for their golfers. So… Read more »

How does the 365PF compare to the 915F/H? All other factors being equal, would the 365PF provide a higher ball flight? Thank you, I’m a big fan of the 915F/H and all of the other Wishon clubs I’m using.

Travis I too am a big fan of the old 915F/H and always have been. I think it was one of the real “sleepers” in my past stable of old designs and I was sad when the demand dropped after several years of popularity, to force us to discontinue it. Wish I would have selfishly stockpiled a bunch of the 21 and 24.5 heads in that model!! HA! Anyway, the 365 is pretty close and most definitely the closest to the 915F/H among anything in the current product line. I do have my eye on the upcoming 927 woods and… Read more »

Thank you Tom. I think I remember reading a discussion, although I can’t find it on the site now, about someone building the 365PFs to single-length fairway lengths. Do you view that as a possibility that would allow the fairways to include a 25* fairwat vs using the EQ1-NX?

Travis It all depends on the shaft weight, grip weight, final length as to whether the 365s could be made to a single length in their assembly. THere are a TON of variables involved in just those three things. Send me an email to tww@wishongolf.com and ask me to send you an Excel file with which you can come pretty darn close to predicting assembled swingweight based on inputting the exact length, shaft weight, grip weight, and head weight. With that you can answer your question much better than I can because you know what shaft, grip, length you want… Read more »

Question about the 365PF 7 and 9 woods. If these two heads were to be used as a replacement for hybrid irons, should a hybrid shaft or a wood shaft be used?

George The main difference between hybrid and wood shafts is that hybrid shafts are intended to achieve their proper flex and bend profile when played at hybrid club lengths, while wood shafts are intended to be played at fwy wood lengths. A typical 7w loft is 21*, same as a lot of 3 irons and 3 hybrids while a 9w is going to have a loft about the same as a 4 iron or 4 hybrid. Yes, there are differences there but that’s basically the standard. So if you plan to use the 7w as a 3 hybrid at a… Read more »

Tom, I have a question about a 9 wood. I’m wondering if it might give me some options with my longer irons and single length hybrids. Let me explain. I recently got two single length 41″ fairway woods, a 4 and a 7. I’m really enjoying them, finding them easy to swing and impact results are very good. They are my most consistent clubs. I’m hitting the 41″ 7 wood about 160 yards very consistently. But I’m having trouble controlling the single length hybrids which are 38″ long. I hit my 5 hybrid about 145 yards maximum and it’s hard… Read more »

Steve First off, on the matter of the EQ hybrid and your accuracy with it, did the clubmaker fit you for the LIE of the hybrids when they were made to single length? That could be an issue if this was overlooked. The hosel of the EQ hybrids is bendable – not quite as much as the 775/929 in our line, but most clubmakers with experience and the right bending machine for hybrids or woods can get 2-3* change in the hosel bend for lie. On the 9w matter, it really, REALLY saddens me that just not enough of the… Read more »

Thanks for your thoughts. Then I’m going to move on getting a 9 wood now. Will work with Ed Ellis to try to match my single length 41″ 4 and 7 woods as close as we can. We’ll confirm my hybrid lies too. I’m betting they are ok but good to affirm. In no way are the clubs my singular problem. My swing is the limiter. We’ll move to driver next. Your suggestion a few weeks ago about gripping my 45″ driver shorter is proving spot on, at least for me. My shot dispersions off tee are much better and… Read more »

Tom, Ed Ellis ordered a 9 wood 365PF head yesterday. We’ll give it a try in several weeks. I strike my single length 4 and 7 woods better than any club in my bag. I’m hoping for similar results when Ed sets me up with the 9 wood. Will see. I’ve never swung a 9 wood before. But I borrowed an old Callaway 9 wood yesterday playing with my golf buddy. Its shaft was a little stiffer than my new Wishon single length woods, but I had enough feel to make reasonable contact several times with the 9 wood. I… Read more »

Tom, A couple weeks ago, Ed gave me the 9-wood customized to match the 4 and 7 single length woods I already had. It has the feel of the first two and its performance fits nicely within my bag. The 9 wood is giving me consistent mid-range options, something I really need with my game. The bounce in the wood is also helpful for strikes that are behind the ball. Thanks for your advice on the 9 wood. Driver is next. Choking down to 43″ is proving a good indicator of club length that works best for me. I’m beginning… Read more »

Tom, This is an update on the single length woods Ed Ellis has made for me. The first two were single length mounted on Prolaunch 45.R shafts. My last, a 9 wood 365 on the same shaft has been a great complement to the first two. My bag is pretty well set now with the 9 wood addition. I’ve substituted it for my 5 single length hybrid largely because the 9 wood is a bit more forgiving and I have some overlap with my 6 single length hybrid and the 5 hybrid. I have 37″ single length from LW to… Read more »

Hi Tom could you build one set of clubs for me , I live in Canada . Sorry one length cubs . Thanks

Anselmo I am sorry but Diamond Golf who distribute my designs to clubmakers do not offer the service of building clubs directly for golfers. The manner of the business is that we rely on the independent custom clubmakers to fit and custom build my designs into finished custom made golf clubs for golfers. We feel that custom fitting is the ONLY way to obtain the best equipment to help golfers play to the best of their ability. We would never condone building my designs to a series of one standard specs in the way that all the big name companies… Read more »

Hi Tom

I’ve become interested in your clubs after searching for flatter lie angles in fairway woods, and finding out that the hosels are bendable. That is exactly what i am looking for. My question about the 365PF model is about the range of bend – it says +/- 2 degrees for these, although generally the other woods and hybrids seem to indicate +/- 4 degrees. Is this a typo, or is there something specific about the 365PF that results in the lesser bending range?

Thanks

ALEX The 365 fairway woods are manufactured in a different construction from the 929HS woods so that accounts for the little bit smaller range in hosel bendability for the 365. The 365s are investment cast while the 929’s are 4 piece form forged which then gives us the chance to use a 304 stainless alloy for the hosel to enable it to be bent +/-4* or even more while the 431 stainles of the 365’s with heat treatment reduces that bendability range to +/-2*. So if the player needs a much greater change in lie or face angle than the… Read more »

Hello Tom, I appreciate the time you take to answer people’s questions. Quick question on one length. I have had your Sterling irons pretty much as soon as you came out with them. I absolutely love them and the one length concept. I use the Sterling 5H to 9 iron. I have 4 single length wedges. The PW and GW are stock length and SW and LW are both lengthened to match. I never hit full shots with the SW and LW so my gaping is still correct. I also brought the single length concept to the other end of… Read more »

Tom my question is in regards to measuring this fairway wood and your other offerings as well. What perplexes me about your company is that you claim to be for custom fitters yet you dont give any information on how to actually measure the specs on the clubs. I have checked the specs that the clubs are said to come with and I have no clue where they got what they got. This includes using your stated face width and dividing by 2 and every other imaginable option. I believe you told me at one point that the edges of… Read more »

Andrew I do not think I have ever been successful in teaching anyone how to measure head specs unless, 1) they were with me in person in my workshop, or 2) they sent me a box of heads that I measured and sent back to them with my measurements written on the heads. In this method the clubmaker would put the heads into the gauge and adjust the gauge to the measurements I wrote down. Then the clubmaker would look closely at the touch points on the head to know how to fixture each head in the gauge. I am… Read more »

Hi Tom,

Thanks for the response! I was hoping for the smash factor info on the 365pf head, sorry my initial inquiry wasn’t too clear.

I have hit the 950hc and think it’s terrific.

I was also curious if the sound from this head (365pf) is noticeably different from the others due to the steel construction.

Thank you

KYLE Sorry for the misunderstanding on your request. The 365PF smash factor should be in the area of 1.40 to 1.42 because it is not made with a high strength steel alloy for the face as are the 929 and 950 woods. The 365 is a conventional 2 pc investment cast construction so the face is the same alloy as the body and cast along with the body, not separately welded to the body as are the 929/950. But I did select an alloy that I could thin a little bit to try to eek out a little more COR… Read more »

Hi Tom,

Was going to build a 950HC, but am curious to try this model as I haven’t seen it yet. When you say it has the highest smash factor for an investment steel fw, how does that compare to something like the 950HC (which I assume is ~.83 COR).

I’m also curious how the acoustics compare with the other fairways you offer.

Finally, thank you for the adjustable hosel and hand selection options – it’s truly a game-changer and it’s too bad other companies haven’t followed suite.

Thank you!

Kyle

KYLE In face to back and toe to heel size as you look down on it in the playing position, the 950HC is slightly smaller than the same dimensions you see on some of the fairway models from the big OEMs like TM or Ping or Titleist or Callaway. The face height is about the same as what you see on these other companies’ fwy wood models at 34mm. It is made so when the face specs are hit dead on in production, the smash factor as read by a good launch monitor like TrackMAn or Flight Scope will be… Read more »

Hi Tom, first of all thank you for all your efforts in club making design and making that knowledge accessible for those willing to learn. I am an engineer by trade and took up this hobby some 20 years ago and continue to learn more from your articles and books and really appreciate your passion to educate and share your wealth of experience. I am in the middle of a club build and have combined the 979ss irons with the 365pf woods. The irons set is completed (5i to SW with the green S2S shaft A/L flex) and my customer… Read more »

DAVID Thanks so much for your kind words of support and appreciation for the information ! I do appreciate that and am pleased to hear with your technical background that the information is helpful and interesting to you. I very much still prefer fitting golfers with a one inch progression for length with any model of fwy woods. Doing that definitely helps ensure that there can be a decent distance difference between woods whose loft only may change by 3* from club to club, especially the slower swing speed players. Thanks again and the very best to you in this… Read more »

What lengths did you design these fairway wood heads to be built at? I know you designed your drivers to be built close to 43.5 inches. If I built a set of 5,7,9 woods following a driver at 43.5 inches do you start at say a 42.5 inch 3 wood and just go a half inch shorter every club?

Hi Tom, After getting fitted by Tony Wright in Oak Ridge, TN with a 919THI Driver that I am now hitting 20 yards longer (with a 2 inch shorter shaft no less) I am going back to be fitted for the rest of my bag this Friday. I am intrigued with the idea of getting a 3 through 9 wood to replace my current 3 and 5 wood, and 3 and 4 hybrid. If I understand your comments correctly, I could use more of a hybrid shaft length in the 7 and 9 wood (I like a regular 5 wood… Read more »

Sorry – just to clarify my question, using a 7 wood head to replace my 3 hybrid, what would be the difference in using a 40.25″ shaft (my current 3 hybrid length) vs a 40.75″ (splitting the difference) vs 41.5″ shaft for a normal 7 wood.

SEAN: Thanks very much for taking the time to share your experience with us about the driver and to pose the questions for the woods to come. I am not surprised to hear your results because for one, going shorter with the driver is such a good idea for 99% of all golfers, and two, in working with Tony you are working with one of the very best fitters in the whole country. I kid you not on that. I’ve known Tony for many years and he is a continuing regular in technical questions and discussions with me about all… Read more »

Hi Tom I’ve got so many of your models now that I find that I’m commenting on every page now! I recently bought a 365pf in 16.5* for my wife. The club is absolutely stunning. My wife can hit the club 180m (nearly 200 yds). She has never carried more than a 19 deg before, so it was a risk. But she hits it so well and now has an extra 20 yards up her sleeve.. Quite recently I also bought myself “new-old” stock of the 915FH in 18.5*. It is very solid but despite a few tweaks, we found… Read more »

Frazer: Then that is a remarkable accomplishment to be on each comment page on our site !!! Well done !! Wow, you wife must have very decent clubhead speed to hit the 365-4 wood nearly 200 yards. That’s outstanding ! But also very nice to hear that you have discovered the secret of the 365PF for yourself too ! You know, this 365PF model is not selling that well and stands a distant 3rd behind the 929HS first, then the 950HC. I think it is because people now look at Wishon Golf for our high COR designs. While the 365… Read more »

How would these perform out of the rough if I were considering a combined fairway wood/hybrid set makeup?

LOUIS There is no question that the smaller the sole area, the less drag/grab there will be on the head when hitting shots from rough. but each golfer is different in terms of the things that dictate how much the rough hangs up any club on a shot – clubhead speed, angle of attack being the key things that dictate how well a player can get a clubhead through the rough. not to mention the variability of the rough itself in different areas of the country due to grass length and grass type (Bermuda vs Rye grass vs bent, etc).… Read more »

Tom, I just completed building one of the #9 365PF models w/S2S Blue hybrid shaft/blk rib grip. Seriously, I am just overwhelmed with this club. I am a long time customer with your products and believe me when I say I have tinkered with many, many club configurations. I hope others will try this model especially if one is after initial easy launch with a stable/tight ball flight. I have borderline slow swing speed and its rare I can build a hybrid in the 24 degree loft range to what I fit for length wise and get the carry distance… Read more »

Well thank you, thank you very much for taking your time to come and let us know your experiences with the 365 wood. We’re really pleased that you like the new design and that it is performing well for you and giving you what you wanted in the model. When I finished this model last year, I really thought this would be a genuine “sleeper” model, meaning it was a whole lot better model than most people would realize, given that it is sort of overshadowed by the high COR models 929 and 950. Thanks much for your support !!… Read more »

Hi Tom,

I own many of your products;919,775,560. I’m quite good with iron and hybrid, so that I never own any fwy wood. If I want to have my first fwy wood which model and loft is reccommendable? My swing speed is about 93mph.

ROY You know, really, it is very possible to cover the distances of most of the fairway woods with hybrids. So if you have always preferred elements of the hybrid – smaller shape/size, shorter length – then don’t feel compelled to have to use fwy woods. About the ONLY place you’d miss distance with a fwy wood vs a hybrid would be if you have the ability to hit a 3 wood well up in the air to fly. 3-woods being 14, 15, 16 loft means that you do not have a hybrid at that low of a loft. But… Read more »

Tom,

Would you recommend these fairway woods to someone who is a scratch golfer or do you have another design you would recommend? I’ve been playing your Driver, fairway woods, irons and wedges for years and love them. I’m looking for new fairway woods and any help would be greatly appreciated. On a side note, I am going to be giving your Sterling single length irons a go here soon and am trying to fill some gaps from my 919 driver to the sterling 5 iron. Thanks – Robert

ROBERT: The 365PF can certainly be played by a scratch golfer. The choice of a fwy wood should be made on the basis of, 1) does the golfer really like the size, shape and especially is the face height not too tall to hurt his confidence in getting the ball consistently up to fly, nor too shallow to cause a potential problem with sky-ing the ball, 2) is the smash factor good enough for the golfer’s clubhead speed – avg to slower speed players should be using high COR face fwy woods, but players with higher speeds don’t have to… Read more »

Hi Tom

I have been buying your products for year and have always enjoyed the looks and performance. i had the 929hs 4 wood and loved it but then i saw the 949 with the hotter cup face and jumped all over that. Now i do like the distance of the 949 but felt like i was able to hit the 929 better from the fairway. where does this new 365 fall i guess i’m like everyone else and looking for the best on off center hits but is goof from the fairways which would you recommend ?

thanks Michael

MIchael I designed the 365 woods to be “in between” the 950 and 929 in terms of face height – not as tall as the traditional 950, not as shallow as the 929. Do not let anyone tell you that any fairway wood has good off center hit forgiveness. Even with a larger traditional size fwy wood like the 950, that head size and face area is way too small to ever hope to offer an off center hit forgiveness that could even be half of what is possible with a driver. No scientific way to get that done. Nada.… Read more »

Tom,

I am not a tall golfer and I have all of my irons bent 2 degrees flat. I have always felt that if my fairway woods rested more flat, I would be able to hit them better. Every source/person I’ve talked to says that lie angle doesn’t matter for fairway woods/drivers. Can you speak to that at all? I see that you certainly have adjustable fairway woods/drivers, but could you articulate the difference lie would make?

Thanks,

-Josh

JOSH First off, my sincere apology for the big delay in responding. The notification feature for posts and comments was not working so we haven’t seen the posts being made here for us to respond. That’s a big Ooops. Sorry about that. The whole reason I designed a bendable hosel on our drivers, fairway woods and hybrids was because my research work began to show that it was important to have the lie correct with these lower loft heads, but for different reasons – some actual performance related but some were psychologically related too. With fwy woods, we found if… Read more »

First thank you for making truly amazing equipment and all you do for golf. Now my question is what is main difference between these new 365 woods and the 929? I have 4 wood in 929 that is my best club in my bag I have struggled with hybrids and was reading about using one of these or even 929 like a hybrid just wanted your thoughts on what is the biggest difference between the two

LEVI Thanks so much for your kind words. Very much appreciated for sure. 929HS has a slightly more shallow face height than the 365PF,which means is has a slightly lower center of gravity to offer a slightly higher launch angle for the same loft. Also, while the smash factor of the 365PF is pretty darn high for an all investment cast fairway wood, the 929HS is a definite high strength steel thin face so its smash factor will be slightly higher – like 1.49 for the 919HS vs 1.44 or so for the 365PF. In actual distance terms, that’s really… Read more »

Tom,

I currently have a 335HL #6 hybrid that I absolutely love. My question concerns adding a #4 or #5 hybrid. Note I am not high swing speed player, traditionally have played high loft fairway woods vs a 3-6 iron mainly for launch/carry. Could you explain differences between a 335HL 4 hybrid vs your new 365 #9 wood/hybrid club head? Specifically, launch angle (i.e. is one design much higher vs the other?), smash factor,etc. Thank you.

BR: I’m going to say based on my knowledge of the two models in development that for the same loft, the 335HL would hit the ball higher than the 365PF wood. Smash factor will certainly be higher for the 365PF, I can assure you of that. But for an avg to slower swing speed player, that is not going to translate into much of a real distance difference from that higher smash factor in the 365PF woods. In the end, the decision would probably come down more to if the 335 is made shorter in length, would you hit that… Read more »

Tom, I’m working on getting a better set make up. My staple clubs are 5i thru LW (+-170yd-in, 5i-38″, average 82mph), 4 wd, and the Driver. I want to have two hybrids at iron lengths for my +- 180 to 190 yd clubs. I’m thinking about first testing a 5 or 7 wood at 2i or 3i length length, 39-1/2″, 39″ with the hybrid red R shaft. Since the 365PFs are not available, is there any reason that the 929HS wouldn’t work just as well for a hybrid? Could you please explain pros and cons of 365 vs 929 as… Read more »

ORAN yes, because the 929HS also has two separate weight addition positions, it can be used to make a hybrid. As you make a wood like this shorter to become more of a hybrid, there is a need to add more weight to the head to achieve a desired swingweight at the hybrid length which is shorter than a typical fwy wood length. There is a weight bore on the toe end of the sole and at the bottom of the hosel bore, below the shafting bore. Both take up to a 9 gram tungsten weight if needed to get… Read more »

Tom, I notice that the 365PF description indicates that they are also an option for hybrids. Does this mean that the S2S hybrid shafts would work well for these heads for hybrid lengths, etc? Thank you.

ORAN Thanks very much for your interest in the new 365’s. yes, if the 365 #5, 7 or 9 are intended to be built as a hybrid, we would recommend that be done with one of our hybrid shafts and at the iron type hybrid lengths we have always, always recommended for our hybrid models. The bore of the 365PF is 0.335 so it fits either our wood shafts to be used as a fwy wood, or our hybrid shafts to be used as a hybrid. The reason we have always taught that hybrids should be fit to iron lengths… Read more »

0.370 bore diameter? Is that correct?

TOM

yes, all our iron and wedge designs are always going to be manufactured with a 0.370″ parallel bore. There are SO MANY MORE shaft options for fitting different golfers when you use a 0.370 bore than there are with 0.355 taper tips.

TOM

TOM

I am sorry, I did not happen to see that your question referred to the 365PF fairway woods – there were so many comments here all about the single length sets and yours came into our site among those so I just assumed it was referring to the single length iron sets. No, the 365PF woods are 0.335 parallel bore – I will check that page on the site and if we made a mistake about this bore diam for the 365 woods, we’ll get it fixed. Sorry about that,

TOM