950HC FAIRWAYS

THIS PRODUCT IS NOW DISCONTINUED

Traditional Shape and Face Height, High COR Design… For Distance with Penetrating Shot Trajectory.

Features:

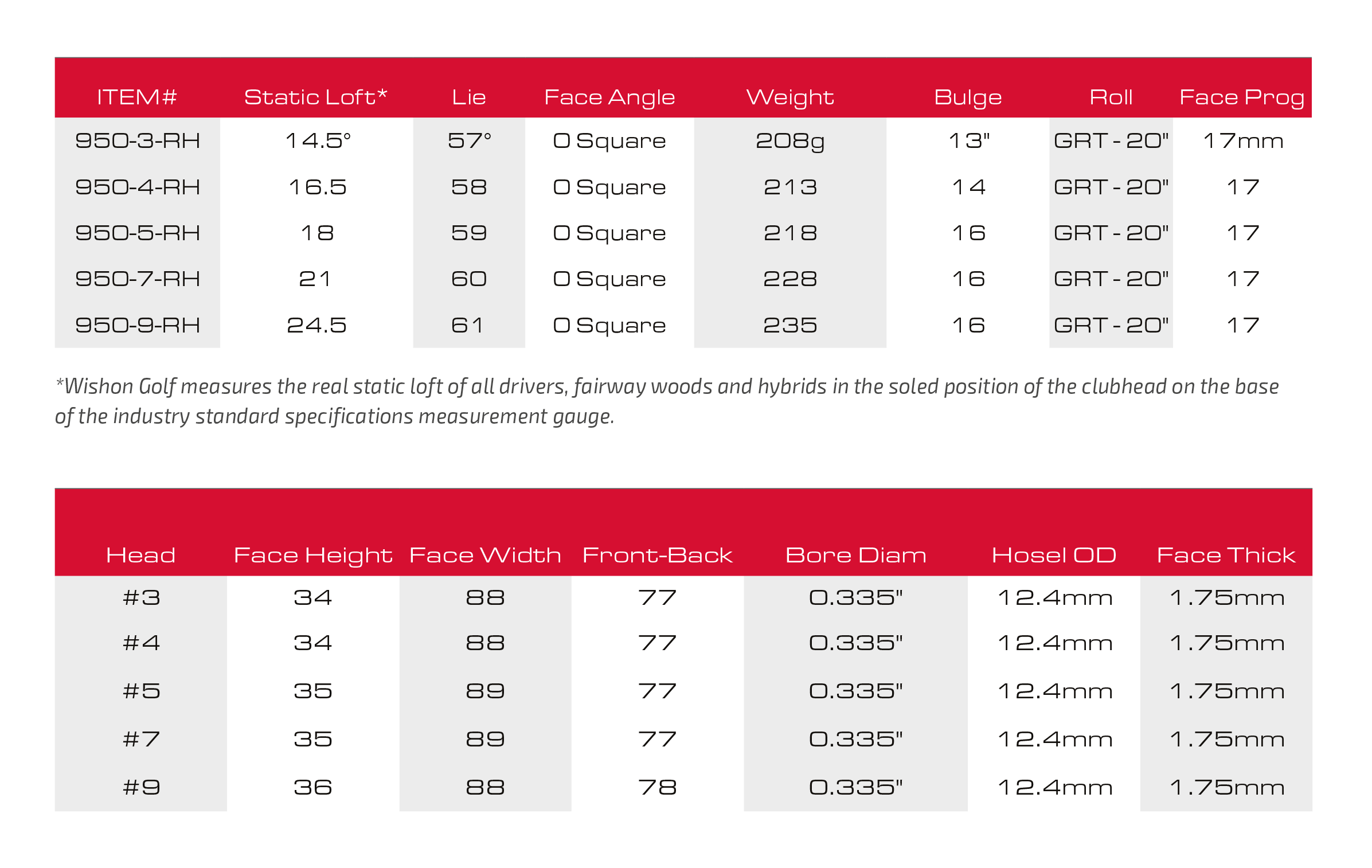

- The new 950HC is the second generation version of the 949MC with a traditional shape and size with 34mm face height and bendable hosel to offer custom lie and face angle fitting options to fit all golfers

-

New semi-cup face construction to ensure maximum COR and offer a better level of off-center forgiveness in a fairway wood design

-

Twin weight bores for a wide range in length, shaft weight, swingweight fitting options

-

Available in RH in #3 (14.5°), #4 (16.5°), #5 (18°), #7 (21°) and 9 wood (24.5°) to expand the fitting options for players. Gloss metallic black with satin chrome face, sole and hosel.

© COPYRIGHT 2025 WISHON GOLF

I came across a 950HC 5 wood and thought the tall face would be helpful. I have a EQ1 5 hybrid that I am somewhat inconsistent with. I am a higher handicap (20) golfer, age 69. After a few rounds I have hit the 950 very well. When I use it off a low tee for longer par threes the difference is dramatic; long, high, consistent. Off the fairway it seems I hit it as high or higher than the hybrid, which surprised me. A while back you indicated a new tall face wood might be in the works to… Read more »

PETER Nice to hear that you tripped across one of the 950 woods. TO be honest, I doubt I would do anything like that again because there are so many more golfers who would benefit from normal to shallow face woods than there ever could be that would do better with a taller face wood. Most golfers do have a problem hitting the ball consistently high to fly with a wood for shots off the deck anyway, and a face height up over 35mm doesn’t do anything good to help golfers who do have that problem. Good for you to… Read more »

Hi Tom. What 3 wood would you say is the closest match the the 950hc. Really enjoy the semi cup face style and was wondering which one of your would consider the closest thing to it. Thanks

JAY That’s a bit of a tough one to answer since the 950 has a little taller face height than any of the current fwy wood models in the line. But I would say that the EQ1 3w would come the closest in terms of COR/CT performance since the EQ woods are all high strength steel thin face models. But the EQ woods do have a different profile shape for sure than the 950 so that is a difference, aesthetically speaking. If shape is very important in another 3w, then it might be the 365 3w that would be closer… Read more »

Hi Tom,

I am just curious why you discontinued this model? I understand the challenges of inventory, production, and sales. I just wish you had a taller faced fairway in your line up.

Thanks for all you do.

BEN As is always the case, the models that get discontinued rank last in sales demand among all other models of the same type. When we had three fwy wood models (929, 365, 950) the 950 was last. And then when we added the EQ1 fwy woods as part of the total EQ1 single length family, because the EQ1’s could be made to conventional fwy wood length as well as single length or any lengths in between, they jumped up ahead of the 950 and 365 both. Since we can’t handle 4 different fwy wood models for a company of… Read more »

Are these available nowadays in left handed. I need a good 3 wood. I just got the Sterling one lengths and absolutely adore them. Have never ever hit the ball this well and consistent. Thank you.

Dallas

DALLAS Many thanks for your visit to our comments section and even more pleased to hear that your experience with the Sterling Irons has been so good. for a designer being able to hear something like that is really better than the fun of designing clubs in the first place! Very sorry to say that the 950’s never made it into a left hand version. Whether a model can make that jump always depends on the demand being high enough for the right hand model. Never in all my years of designing heads have I seen a left hand model… Read more »

I think the 929 would be a great 3 wood and am thankful it is offered in LH. One more question Tom, as you have been very kind answering these questions, and I am very thankful that you can share your vast knowledge in club making. The 919THI Driver comes in LH at 11 degrees. I read somewhere that it is possible to lower that loft by 1 or 2 degrees. Is that correct? I am working right now on what my specific loft should be for a driver. I have had such a great experience with the Sterling Irons… Read more »

Good Day Tom! I hope this message finds you well. I have started making clubs for myself, wife and son. I was able to get a set of the S2S white iron and wood shafts. I also was able to get a friend to send me a set of the Sterling single length 8 iron lie heads. Since this is my first time with these irons can you tell me what length to cut the Raw S2S shaft ? I know that the shaft should be 36.5″ but what would it be raw length before installation ? Many Thanks, Dave… Read more »

Dave: Good for you that you have begun to build clubs for your family’s needs! I can imagine where you live that it would be far better to be able to do your own work, not to mention regardless where you are it can be a lot of fun both to do the work and to experiment with the results. When building ANY set of irons, you always do the tip trim for each shaft first. Then you abrade the tips, install the ferrules, and slam the shafts into the hosels to push the tip to the bottom of the… Read more »

Thanks Tom for all your help.

Just to be clear you mentioned

“When building ANY set of irons, you always do the tip trim for each shaft first.”

What length is the tip trim for the 8 iron length shaft ?

Please forgive my ignorance here. My learning curve is all up hill.

Thanks,

Dave

DAVE: There is not a single standard for tip trimming for each head for each shaft in the industry. It can vary due to the construction and design of each shaft model so you always have to reference each shaft maker’s tip trim and installation charts that they provide on their websites or in their catalogs if they still print a catalog. For all of our shafts, we keep all this information on line here – https://wishongolf.com/s2s-shaft-trimming-chart/ . The tip trim for an 8 iron with the White R, White S, Black R, Black S, Blue A, Blue R, Superlite… Read more »

Hey there TOM, how are you? I have a 949MC 14 degree and LOVE it… the feel and the performance are excellent. The only negative, it’s an older model and not your updated 2014 model (no second weight bore on the sole). Because of this I am looking at your 950HC as a replacement. Since I am a Sterling Irons lifer, I am looking to make the fairway woods shorter and of course keep it at a decent swingweight … so, the 950HC should be perfect for my needs. I just wanted to ask about the sole weight bore. Does… Read more »

Hi Jake, doing fine these days, thank you ! It’s really nice to hear you are solid behind some of my designs for your game. That’s really great to hear and I thank you so much for your support! Yes, the weight plugs used in the hosel are the same ones to be used in the sole weight bore that is covered with the little TW medallion. Just be sure to epoxy the weight into the bore and also when you install the medallion, put a tiny little dab of epoxy on the flat surfaces, peel off the paper backing… Read more »

Thanks SO MUCH for your reply TOM… awesome support, as usual! Very happy to hear that I can use those weight plugs and setup a new 950HC club in place of my (beloved)949MC.

I’ll putting the 590DIH into action Thursday morning. It’s gonna be looooooong next couple of days, lol!

Thanks again TOM,

Jake 🙂

Bit of a crazy question here. I know the option to change the bore from .335 to .370 is really designed more for the hybrids and driving irons. BUT, can that same service be used for the fairways?

KYLE

Reaming any 0.335 bore to a 0.370 bore could be done, but if the attempt is to try to make fwy woods be a part of a single length iron set, it would not likely work. Fwy wood heads would be too light to achieve normal swingweights at iron lengths, and iron shafts are stiffer than wood shafts of the same flex and model/brand.

TOM

Thanks Tom The actual idea is to use the S2S stepless shaft through the whole set. I’ve long struggled to find a graphite shaft that I’m comfortable with, but I’ve had steel-shafted drivers in the past I liked. I tip trim the stepless stiff shaft an additional .5 inches in the irons. So the plan would be to have the 2 hybrid tip trimmed a total of .5 inches and then move into the regular stepless shaft for the fairway woods and driver (tip trimming for each to match the progression of the irons/hybrid), with those clubs playing about 41.5… Read more »

KYLE You can always try ONE fwy wood with a Stepless iron shaft but I seriously have my doubts about whether you’ll like this. Iron shafts are intentionally designed to be TWICE as stiff as wood shafts, for the same model of shaft. So if you had a True Temper Dynamic steel shaft in the woods (this one steel WOOD shaft is still available, though it is about the only one since graphite has 99% of the market share for drivers and woods) and if you had the same flex of Dynamic steel in the irons, the iron shaft is… Read more »

Tom,

I’m looking for a 3-wood that I can bend flat. No one makes fairway woods that are flat enough for me. I’m 3 to 4 degrees flat with my irons and would love to find a fairway wood that is quite flat.

I’m 50, and a competitive amateur. Currently +1.7 and playing an M2 3-wood that I really like, but would love even more if it was flat!

Thoughts?

David Ober

DAVID BOth our model 929HS and 950HC are made with a bendable hosel that will allow the lies to be bent 4 deg more flat or more upright than each wood’s lie design spec. For example the 3w in both sets could achieve a lie of 53*. As with all my head designs they are available only from custom clubmakers. To see if there is a custom clubmaker near you, you can go to the FIND A CLUBFITTER search tool on our website to input your location. The clubmakers closest to that location will be displayed so you can contact… Read more »

Tom,

I’m looking for a 3-wood that I can bend flat. No one makes fairway woods that are flat enough for me. I’m 3 to 4 degrees flat with my irons and would love to find a fairway wood that is quite flat.

I’m 50, and a competitive amateur. Currently +1.7 and playing an M2 3-wood that I really like, but would love even more if it was flat!

Thoughts?

David Ober

Hi Tom, I love the Sterling irons and was wondering if you’ve put any thought into making same length woods? In looking at the weight of each head, it seems like it would almost be possible to get them hand selected at heavier weights in the 14 and 18 degree model, lighter in the 21 degree and than with some tip weights and lead tape make them all around 224 grams…do you think making them around same length one would find success? I swing around 110 with the driver so swing speed wouldn’t really be an issue. I just love… Read more »

AUSTIN Yes, but I have kept getting waylaid on that project thanks to other things that pop up when you first retire !! HA ! Or I should say SEMI retire, which is more appropriate since I am still supposed to be working on projects related to design and tech stuff ! It will be a combination of fwy woods + hybrid(s) and will not include the driver. You cannot bring the driver into a single length picture because you’d end up making the driver too short which would cost people distance. Even with much better accuracy, if you take… Read more »

Very cool! Didn’t know you were even working on something like this. Any idea how they will look? Think they will mirror one of your current models?

AUSTIN Believe me, the shape is the easiest part !! I went back and forth a few times on what single length to do the woods/hybrids and what lofts to make them as well. Shape wise they are going to be a little bit more similar to a newer fairway wood model I did in 2015 that is still in the Wishon Golf product line called the 365PF. Head shape will progress from traditional size in the lower loft woods to be slightly smaller as it transitions to the hybrids. And the face heights will be in between that of… Read more »

Hi Tom, Recently I ve been occasionally suffering from the dreaded shanks particularly when I’m practicing. To prevent this happening I introduce a 3″x3″x12″ piece of wood on the outside of the ball. This generally focuses the mind, gets my delivery back from the inside and sees the quality of return to normal. On a few occasions I hit the board. This evening whilst using my five wood, yes I can even shank a 5 wood, I hit the board which resulted in some damage being caused to the clubhead. A section of the paint has been dislodge. This section… Read more »

PETER Believe me, I know your pain. . . decades ago in an effort to change from outside in to inside out, I developed a very bad habit in my swing to drop the club too far on the inside out path. Which when done too severely shoves the hosel into the ball, resulting for me what you speak about in your comment !!! Ugh. I too have a trusty section of 2×4 with nails protruding from one side to use for my own anti-S training when it hits me !! Not sure if there are many stores in your… Read more »

As always Tom,

Great information and advice.

Many thanks & best regards

Peter

Dear Tom you’re so cleverand honnest man (I am sorry about not taking care of your natural modesty) as I was wondering why in the past I hit so consistent shots with little heads I asked to André in France to check my swing and woods no problem with the wonnderful 929 woods, but we tried the 919 FW woods which was quite consistent (I own a 919 black 13°, 43,75 ” ) I was not very happy with my driver swing (I knew it was my swing) Il felt more confident with the 950, 3 wood which is amazing… Read more »

Thank you so much Dominique for taking the time to visit our site and share your experience with the custom fit clubs that Andre fit and built for you. It’s a real pleasure for me to be able to hear about your experience because I like knowing that something I created, when fit and built by a true craftsman such as Andre, is able to help a golfer enjoy the game more than before !!! Thank you !!!!

TOM

I have a 949MC 3 wood with 14 degree loft. I hit it too far and too low. While it is an excellent club off the tee for shorter par 4s, I dont need that much length and I need height. I dont know if a 950 HC 15 degree would be the solution. Please comment.

BOB:

I would recommend you think of and take a look at the 929Hs fairway woods. The 929 are a shorter face height model which assures it to have a lower center of gravity than any of our other fairway woods, past or present. The 950 has a taller face height which brings about a little higher CG.

TOM

Hi Tom, I currently have in my bag a driver on a 43″ shaft- reshafted with a Wishon White A Fairway Driver again on a Wishon White And a 2R Cleveland Halo on the original regular shaft. I am thinking of making a change but am not quite sure which route to follow. The questions I hope that you will answer for me are as follows 1. Would a five wood be easier/ the same or more difficult to hit than a 2 Rescue of the same loft on the same length shaft. 2. Is it likely that a high… Read more »

PETER: If the hybrid/rescue club and the fwy wood club are both the same length, same loft, same everything – it would only be a psychological reason why a golfer would hit one better than the other. In that case, some people like the shape of a fwy wood over a hybrid/rescue head and some are the opposite. But typically you do not find hybrids of the same loft as a fwy wood being made to the same length and same everything for fitting specs. Most hybrids are shorter than woods of the same loft. And in that case, IN… Read more »

Hello Tom,

Some guys paints their clubhead with automotive paint (glossy blue, mate white …). Do you plan to propose different colors in the future. Maybe the paint job could be an option proposed by the local clubmaker ?

Frysou Thanks for your interest. I doubt very much if we will offer different color options in the future. For us as a small company, getting into different colors just becomes a big inventory nightmare. Besides, from what we have found in many years of designing heads is that the vast majority of golfers prefer black and don’t want something else. As to your question about clubmakers offering paint options on metal woods, that would be very unlikely. The reason is because proper metal wood painting requires very sophisticated 2 component paints to achieve the proper durability, and these paints… Read more »

Are you going to match the design of the black 919 driver? I just commissioned a driver to be build and love the look at address. If the driver works as anticipated I will most likely be getting a wood or two, and would love for them to match. Thanks, JJ.

JJ Thanks very much for your question and for letting us know that you are working with a clubmaker to be fit into one of the black oxide 919THI driver models. After consideration and polling a number of our custom clubmakers, we at this time do not have plans to offer either the 950HC or 929HS fairway wood models in that same exact black oxide finish. most of the clubmakers we contacted to ask did indicate that the black oxide finish was something the majority of their customers considered for the driver, but for some reason not so much with… Read more »

Tom, The 950HC fairways are very nice. They are the perfect size and shape that I like to see at address. I’ve replaced my 3 and 4 irons with the 7wd and the 9wd. Lately I’ve been using the 9 wood in place of the 4 and 5 iron. I prefer the 950HC fairways in place of hybrids. Is there any chance that the 950HC will be available in 11 wood? I believe that this 9 wood is quite possible my first favorite club in my bag. Thank you.

ORAN Thanks so much for taking your time to visit and offer your comments about the new 950HC woods. We’re very pleased to hear you like them. In all honesty I just am not sure about the possibility of an 11 wood in the set. We’re one of the few companies to have pushed the envelope a little to add on a 9 wood in most all of our fairway wood models in the past year or two. Even with this, not all that many of the clubmakers are yet pushing the possibility of a 9 wood on the golfers… Read more »

I have just recently learned of the Wishon Irons. I played on a golf tournament and won a set of custom irons from the GOLF STATION in Hurst, Texas. Tim Brantley a former Tour Player brought me in to his AWESOME simulator and had me start with my Vokey 56* and I swung it for about 15 swings, then he handed me the WISHON 557 6-iron and I hit it a few times pretty good. He grabbed a different shaft for me and I hit quite a few more. I was hitting a 6-iron on the screen 186-192 yards and… Read more »

SHANE Thanks so much for taking your time to visit the site and share your comments and experiences from your work with Tim. Great that your good fortune in winning the irons put you in contact with Tim because he is very good and very experienced in the field of custom clubfitting and clubmaking. As the designer, it is very nice to be able to hear that you found the combination with the 575’s that allowed you to experience how the design can perform and feel for you and your swing. In 29 yrs in clubhead and shaft design, while… Read more »

Tom, Thank you for this great 3 wood! I have been struggling to find a 3 wood that I can hit consistently. I went through the “off the shelf” woods from Ping and TaylorMade with little success. They just sat in my bag. Last year I had TC at Perfect Lies Golf in New York fit me for Wishon 560MC irons a 775HS 3 hybrid.The results have been fabulous. I have never been more consistent. So I thought I would give TC a shot at creating a 3 wood that works. Despite the fact that I was only having one… Read more »

STEVE

Thanks so much for taking your time to let us know how well your fitting analysis with Fred was. I know 2 hrs is a long time to travel to be fit but I also know that Fred has always and will always go more than the extra mile to be sure the golfers who choose to work with him are pleased with the results. Thanks again and the very best wishes to you in this great game,

TOM

I plan to have a 950 HC three wood when they come out in May. I love the looks and I will hold up on purchasing a Callaway Xr three wood until after I hit your club. Both have the cup face desing. Thanks so much for your part in design this design (cup face design).

Thanks very much for your post and for your interest. If you do get a chance to hit the 950HC on a launch monitor that measures ball speed and clubhead speed accurately, look for the output from the launch monitor called the “smash factor”. That is the ball speed divided by the clubhead speed. The highest possible smash factor that can be achieved by a clubhead that is conforming to the USGA rule for COR is 1.49 to 1.50. Smash factor is also affected by the +/- tolerances on the production of the face and its thickness. So in normal… Read more »

I live in Colorado Springs. How do I order.

MARK

Thanks very much for your interest in our company and our work. We appreciate that very much. If you are a clubmaker, you can apply to set up an account with us by filling out the information form found here – https://wishongolf.com/clubmakers/catalogetech-newsletter-request-form/ . If you are a golfer interested in being custom fit for our designs, in the Colo Spgs area we would recommend you contact JIm Klingensmith at Accufit Golf Studio – 719-227-0600 or 719-528-8130 to set up an appointment. Thanks very much!

TOM