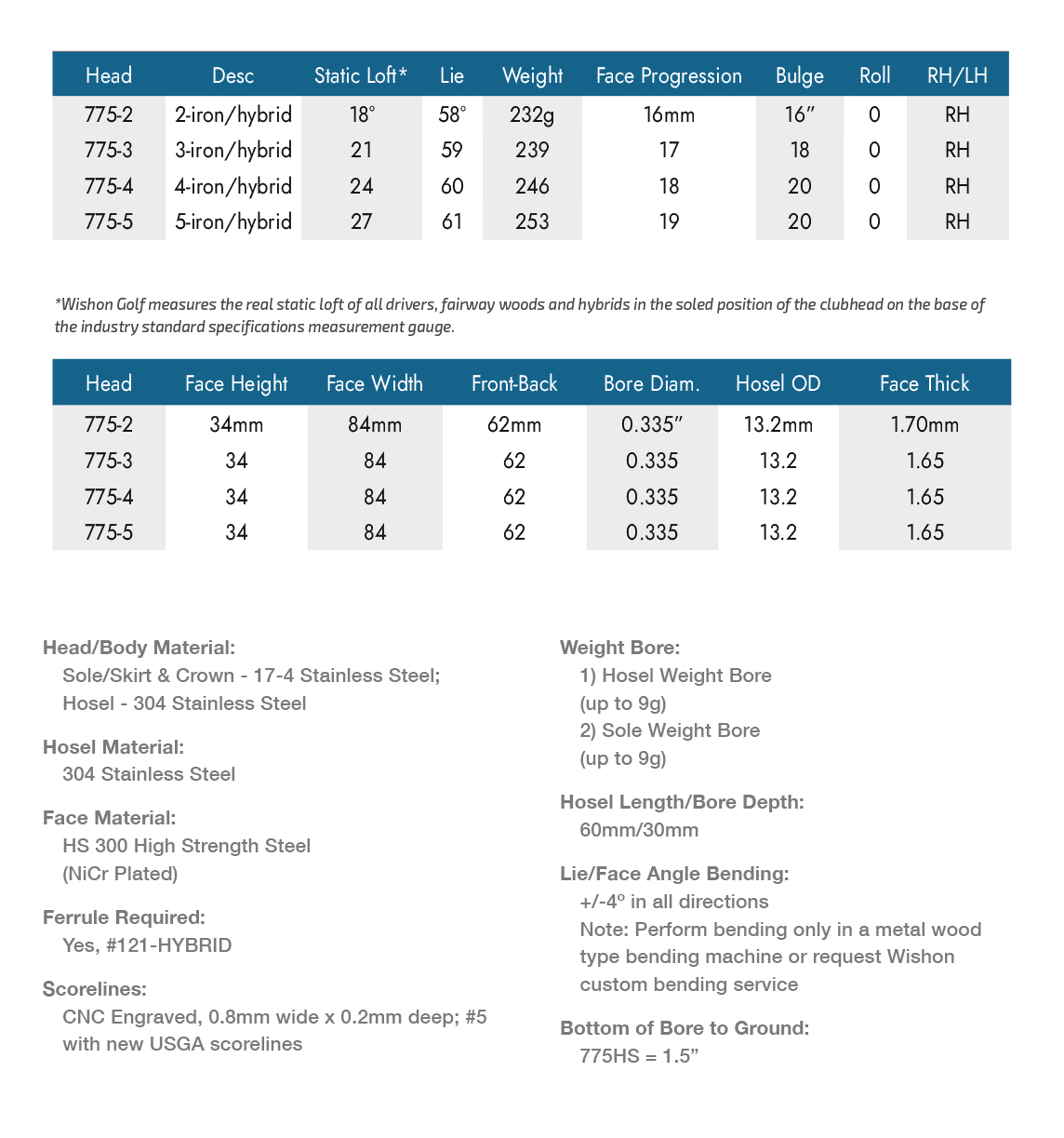

775HS HYBRID IRONS

A Unique Hybrid Design with Thin Face, High COR Performance and a Unique Soft Stainless Steel Hosel for a Wide Range of Lie and Face Angle Fitting Options

Features:

-

Thin, High COR, High Strength HS350 Steel Alloy Face offers higher ball speed for more distance in a hybrid head design. Few companies can offer a high COR design in a hybrid

-

Unique 304 Stainless Steel Hosel allows for much greater ease in bending lie and face angle to broaden custom fitting options (+/-4°)

-

Split Level, Narrowed Sole Width to reduce sole to turf contact for more solid shotmaking from fairway or rough conditions

-

775HS Face Progression is in between that of an Iron and Fairway Wood to enable golfers to play the 775HS with the same ball position and swing motion as an iron of the same loft

-

Available in RH in #2, 3, 4, 5

© COPYRIGHT 2025 WISHON GOLF

Tom,

Will you be releasing a successor to this hybrid with a similar profile (e.g., no visible offset and a face height of 34 mm)?

These are perfect for hitting out of bermuda rough, where the ball may be sitting at different heights (the lower profile hybrids often go “under the ball”).

Thanks!

RAY The 775 hybrid is designed with the face sticking well out in front of the hosel, with a greater amount of face progression. ON the 775, that onset face progression is significant, and from my experience, I have not seen any other hybrid with that much forward face progression. The three new hybrid models I have designed for 2023 (319, 370, 797) do not have that much forward face progression as does the 775. They do have some, but not quite that much. Personally I like this better as when I finished the 775s many years ago, I never… Read more »

Hi Tom

Hope you are doing well!

I currently have a full set of Wishon clubs and I’m gaming your DI 2 iron, which I love. Great from the tee box.

Sometimes I feel like I need a club that goes higher and I’m thinking about rotating the 2 iron with a 3 hybrid. I like both the RS and 775 but I think you mentioned you are about to launch a new hybrid.

What kind of hybrid will it be? Closer to a wood or iron?

Would it be possible to get any news of upcoming hybrids?

J.

JohanE All of my hybrid designs, since day one of Wishon Golf, have been and will be created to be built to the same length as the iron of the same loft because I see hybrids as always being replacement alternative clubs for irons that have too low of a loft for the golfer to comfortably hit high to fly and carry. I never want any of my hybrids, past, present or future, to be built to a length anywhere close to a wood length. That will continue to be a part of the future hybrods that are in the… Read more »

Hi Tom,

I bought the 775 hybrid and its a great club to hit. I have always had a problem hooking hybrids. At set up I find the 775 looks very closed. My question is. can I adjust it to sit more open? Or will that change the loft? I have experience adjusting lofts and lies on irons but I have never adjusted a hybrid.

SEAN That’s really a first for me to hear that the 775 hybrid would ever sit even close to closed. The model has been in the line for over ten years and not once have I heard that. I’d have to see that head with my own eyes to know what might be going on. At any rate, the 775’s (and 929) are designed and made with a soft d304 stainless hosel so they can be easily bent to change lie and face angle. The bendability is so good that it is easy to offer a range of +/-4* change… Read more »

Seasons greetings Tom, Trust you are well. Am having a gapping review, and thought I would reach out to you. Apologies if this is not the right place for the questions in italics. I had 775HS hybrids built in 2010: 2H 18 degrees at 39.75″, 3H 21 degrees at 39.25″ and 4H 24 degrees at 38.75″ with S2S black graphite stiff shafts. I don’t know if they were weighted or tipped, and I guess not as I can’t recall mention during the fitting/build. Is there an easy check on whether this was tipped? And my 5-SW Sterlings Single Length (SSL) are dated September 2016 at 36.5″… Read more »

Andrew Lots of stuff here to respond to so bear with me as this may take some time to answer and explain your options. This is going to take some back and forth starting with you having to do some measurements and respond to me. Best to do that via my email at tww@wishongolf.com and not on the comments forum here. OK, on the Black graphite shafts for the driver, woods and hybrids, you will need to do an ACCURATE measurement in inches + any fraction from the TOP OF THE HOSEL (not top of the ferrule but top of… Read more »

Thanks Tom, that’s been very helpful. Andrew

Hi, I have two of these in my bag and very pleased with them ( also have 318 s which I used previusoly for a while). However the paint seems to chip very easily on the 775s. (-they are kept in headcovers in the bag so well protected ), which tbh makes me think the paint finish wasnt up to scratch (excuse the pun) .This wasnt a problem with the 318s which look fine despite being used more . So, they look a bit beat up after only 6 months of use . Do you know where in the uk… Read more »

Thank you for the comment.

Its great you are happy with the 775’s performance but not so with the paint finish. The easiest option if you are unhappy with the clubs is to take them back to where you bought them from. They should then contact us in regard sorting out replacement heads.

Thanks,

Doug

My bad – I meant Dynacraft not Golfworks

Hi Tom,

I’ve been a devotee of your designs for several years going back to the Golfsmith / Golfworks days. As I’ve recently turned 70, I decided to go with a 6 775HS hybrid vs my 6 771CSI iron. I currently use a 3 and 5 775 hybrids at 22 and 27 degrees that perform well for me.

However I noticed that the 775HS 6 hybrid is not listed on the Diamond Golf website. Is it no longer being made? I don’t see any current Wishon alternatives at a 31 degree loft.

Thanks for your time

Dave

DAVE Unfortunately we are becoming a little bit of a victim of the effects of the golf boom on the production factories that manufacture ours and everyone else’s clubheads. There is so much pressure on these factories to make enough heads to meet the demand world wide that many of them are changing policies. Such as increasing their minimum order quantities to a volume that on some less popular models is creating a real problem. The 775-6 hybrid was by far the lowest selling of the 775 hybrid heads #2, 3, 4, 5 so when we got handed a minimum… Read more »

Tom, recently put the 775hs 3-4-5 hybrids in my bag and love them! My son is left handed, any plans on a left handed line of this model?

JOHN The 775HS hybrids are a little more than ten years old in our product line. We tend to be able to keep models in the product line far longer than pretty much any other golf club company because the nature of custom fitting everything means the fit gets the most attention with the club model being a support to that. We have always been a company that stressed the importance of custom fitting so that puts the actual head or shaft designs as a partner to the fitting process. At any rate, since the 775’s are actually approaching the… Read more »

Tom a couple of questions. I have a customer that wants to buy my older Golfsmith Professional Loft & Lie Machine with the stand. I also have had more than a few customers that would like to bend the hosel for hybrids, fairway woods, and possibly the driver. My machine is in excellent shape and I can pretty much get what I originally paid for the Golfsmith machine. Golf Mechanix has the machine that pretty much bends everything. Tom I am pretty much retired. What would be the best machine considering cost, functional qualities, and ease of use? I could… Read more »

ROGER It’s unfortunate that none of the companies that make LL bending machines truly have a unit that EASILY allows for secure, safe, damage free clamping of drivers, woods and hybrids for bending. I’m sure the reason is because virtually no drivers, woods, hybrids other than mine are bendable. When our company was still operating here in the US, we took the #150951 bending machine from golfmechanix.com and addded on the custom molded back clamp piece to properly adapt it for bending our drivers, woods and hybrids. This was a special back clamp that was molded to fit the shape… Read more »

Tom I have seen the video that you were referring to and I think I can make molds to work. I have a friend who can fabricate just about anything one can imagine so if I run into trouble (I Usually do) he will come up with a solution He kind of reminds me without the accent of the mad genius Mondher. I have the Mondher Golfsmith machine so now I have to rationalize a new loft and lie machine from Golf Mechanix Thanks Tom .

Roger In looking for the molding material for the back clamps, look for a molding PUTTY material. And then you would need a thin rubber pad/sheet piece to put in between the molded clamp and the back of the head to protect the head surface. Also, Mondher does still make and sell the metal base pieces upon which the molding putty is put to form the clamp. These pieces more easily attach to the back clamp mechanism, so you may want to order a couple of those from him. You can get Mondher at mondher@golfmechanix.com to ask him for these… Read more »

Hi Tom, Just trying to wrap my head around the altering of the Face angle. I have your 919 Driver, The 929hs 2, 3, and 4 Woods, and a 3, 4, 5, and 6 775hs Hybrids. I have everything bent 2 degrees flat to help calm down my hook a little, and from what I’m researching it sounds like also having the face angle bent open would also help settle things down a little. My question is the specs say that the clubs can be bent upwards of 4 degrees, is that 4 degrees total, or in a hypothetical scenario… Read more »

NATE Yes, on any of the bendable hosel clubheads that we created (919, 929, 775) the bends can all be done independent of each other, to their max. So if you wanted 4 open and 4 flat you can do that. Or 4 hook and 4 up, you can do that too. But the tough part is as you say, normal iron bending machines cannot hold woods and drivers and hybrids for bending so it takes a clubmaker with a separate machine that is set up to do that. If you can’t find anyone, I can do it but you’d… Read more »

I would like to have more hybrids of you. I need a 6 with 31 degrees of loft, and a 7 with 34 degrees of loft Could you tell me if you make them. I have a 5 which is excellent of 27 egrets of loft. Thanks for you answer

Roux:

We do have the 775HS hybrid model in a #6 that is 31* loft. Sorry that we do not have any hybrids with higher loft than that. We used to have a full set of hybrids – the old 785HF that we intro’d well over ten years ago that was a #2 to PW. In the end I think we were too early with that because we ended up keeping the 2-5 because the 6-PW were not very popular back then. Probably time to think about that now. . . .

TOM

Hi Tom,

I’m planning to work with Bob Howe in Perth (Australia) on a minimalist golf set which will likely include a 3 hybrid as the ‘distance’ club after a driver.

My current thoughts are for this to go with the AW, 8, 6 from the 565MC set.

Is there a benefit of selecting the 775RS over the 318RS?

Thanks

Alastair I like the 775 better than the 318 because of the high COR face and the bendable hosel of the 775. The 318 was designed to be a really good conventional performance hybrid but with a little extra of the slight runner sole, created for a moderate price point as well. It’s a very good conventional design hybrid. The 775 is the bells and whistles hybrid because of the thin, high strength steel face that brings a very high COR for a hybrid. And then the special 304 stainless hosel allows clubmakers to hit pretty much any lie angle… Read more »

Thanks for the detailed replay and Happy New Year Tom.

I’ll say “Hi” to Bob when I see him in a few days.

Hi Tom,

I had a great fitting session with Bob and he passes his wished back!

GREAT to hear Alastair and THANKS very much !!

TOM

Hi Tom–In conjunction with our conversation on your irons, is it safe to assume that if I go with a 4-iron in your set (either the 771s or the 979s) that a properly measured (read just slightly shorter than the 4-iron) 3-hybrid would provide a good gap (not too much–I shake my head at the companies that want to sell you their hybrid because it goes farther. I don’t want one that “goes far” I want one that will provide me with a one-club gap past my previous club!) from my 4-iron? After getting my irons made, the next step… Read more »

ART One thing to keep in mind about my hybrid designs is that I create them to be built to be the same length or very close to the same length as the iron(s) they are replacing in the set of irons. So when I create a 3 hybrid, I intend for it to be made to be a half inch longer than the 4 iron in the iron set and not more than 1 inch longer than the 4 iron in the set. The 771-4 is 23* loft, my 3 hybs tend to be 21*. But hybrids with their… Read more »

Hi Tom–As always, thanks for your help. After reading your other replies, I will definitely have my club maker (a man by the name of Dick Leach in Aiken, SC) be making me a set of 771s (I still await your recommendation regarding my suggested makeup before making the final decision) in the next couple of weeks. Then, the hybrid. After that all I will need are a couple of specialty wedges and my set is complete. (I already have your 919THI driver in my bag)

Thanks again.

Art

Hi, Tom–Once again, my bad. I just saw your answer to my question regarding set makeup and lofts. Sorry for the confusion. I can’t wait for Dick to get going on my new set. Now I have to decide on what shaft I will use and we will proceed from there.

Thank you for all of your help. I will let you know the next time I shoot (or better!) my age. LOL

Hi Tom,

i have a client who is currently using SSL irons 5-LW at 8i length (36.5). He’s chosen to replace his current hybrids and 5/6 SSL irons with 2/3/4/5 775HS hybrids.

Should i make these to standard variable lengths (39.5/39/38.5/38 inches) a i assume they cannot be all the same lenght?

thanks rob

ROB

If he wants to use the 775HS hybrids, they cannot be made to the same length as the SSL irons. Their head weight is designed only for normal hybrid lengths as per the lengths you listed in your question. With the dual weight bores in the head though it could be possible to make them all be 38.5 to 39″ depending on the weight of the shaft and weight of the grip. But that might be too long for the #5 in the set.

TOM

Tom, I’m going to have a meeting with Ed at Ed’s Custom Golf in next couple of days. Really looking forward to getting his help retooling my bag. During the last couple of months of practice I’ve really come to rely on my hybrids off the tee and with my 2nd shots. I simply find them more reliable with my swing. I have a question about developing a hybrid to complement my 7 iron, perhaps my smooth 6 iron swing. Monday night I hit 6 iron on a par 3 hole that requires careful distance control to avoid going into… Read more »

Steve There can be several reasons why you see a bigger distance gap between the 6 and 7 iron, some which could be there all the time and some which just happen when you make a different swing motion with one of the irons. First off is the loft of the two irons. EVERY iron ever made is subject to a normal +/-1* tolerance in loft and lie from the normal course of production. Depending on the quality of the iron and company, it can occasionally be more than this. so there is always a possibility that if the normal… Read more »

Thanks Tom. Your comments make sense. I have never had my irons checked for actual loft. Be interesting to see, particularly between my 6 and 7 clubs. I am intrigued by the 775HS spec sheets, in particular the 775-6. Really looking forward to re-tooling my bag with Ed’s help. Thanks again for your advice. Steve

Tom, I really appreciate your feedback to my question about fairway driver/woods. Your thoughts have been helpful as I frame my thinking on Wishon clubs. I anticipate working with Ed at Ed’s Custom Golf in the next week. I’m going to start with hybrids, then look at driver and fairway woods next. I’ve been practicing with my hybrids much during the last month and have found them my go to clubs particularly from the fairway. I like my hybrids a lot. There are probably a host of technical reasons for my preference but I’m wondering if club swing weight has… Read more »

Steve Without a doubt, swingweight to a certain extent can be a way to get an idea whether you will be able to feel the presence of the head during the swing as a way to have something definite to gauge your swing timing and tempo. Not all golfers can detect the presence of the head during the swing simply because people can have differences in what they perceive to feel heavy vs light. And not all golfers achieve their best swing tempo and timing with the same level of head weight feel. This without question is one of the… Read more »

Tom, thanks for the explanation on swingweight. I’m really looking forward to getting with Ed and obtaining his advice on clubs. My friend is getting his fitted driver this weekend. My turn next. In the meantime I’m looking at my clubs differently, measuring club shaft length, club weight, etc. Your explanation helps with that. Just read pages 150-153 in The Search for the Perfect Club. You talk of the tradeoff for shaft length for drivers pointing out the import of good contact as a way to optimize results. I practiced this past week with my longest hybrid and my driver.… Read more »

STEVE That’s good to know that you are having a good time learning things from my books to help you understand more about your equipment. Being able to hit the ball more consistently solid is SO VERY IMPORTANT to good shotmaking. So many people obsess about distance but in reality as you are seeing, if you want to hit the ball as long as your are physically capable of doing, you absolutely have to hit the ball more solid, more often. Keys to that are club length and club weighting which is a combination of the total weight (sum of… Read more »

Thanks Tom. I’m going to put your advice in place in my golf bag soon.

Steve

Hi Tom, I am curious as to why the hosel bores are .335 vs. .370 when the hybrids are replacing long and mid irons? Would not the .370 shaft be a more suitable match if exchanging out the iron for the hybrid at the same approximate playing length? Can these hosels be shimmed to take a .370 shaft or would that not be recommended? Thanks for all you have done to make golf more enjoyable for the masses.

David Happy to help with an answer to that. Way back when I was designing the very first product line for my company in 2002, I fully intended to design the bore of my first hybrid designs with a 0.370″ diameter so they could use the same iron shaft that would be fit to the golfer’s irons. However when initial testing of my first hybrids revealed that the shot height was just not quite what I wanted it to be for the hybrids to blend well in with a set of irons, I went back to work on the shaft… Read more »

Hi Tom, Have just bought a Wishon 979 SS six iron set (7i-SW) from Sr. Ronald Barret at http://www.rjgolfclubs.com and I consider to add in a 6-hybrid from the 775HS familiy to close the distance gaps in my bag. I (m, 52 years old and a high handicapper at HCP 34, ) have played golf for 3 years and the fitting measured me to a swingweight of approx C9 (my irons and clubs are MOI-matched too). Today do I hit my current 7 Hybrid (Cobra F-Max) approx 125 Yards with little downswing force and midway release. Is the 775 HS… Read more »

Per Thank you for taking the time to stop by with your question. First of all, well done in finding Ronnie to work with for your fitting needs. WE’ve known Ronnie for decades in custom fitting and we know him to be very experienced and very knowledgeable in the craft. He’ll do a very good job for you in your fitting needs. When you talk about forgiveness in golf clubs, you really have to look at two things that comprise the complete definition of forgiveness, ease in hitting the club with reasonable/good consistency and how much distance loss is offset… Read more »

Hi Tom,

Thank you for the explaination of forgiveness in building hybrid-clubs and the factors that determine performance of hybrid clubs for each individual golfer. Yes, it have been a pleasure to work with Ronnie and to learn from his clubfitting / clubbuilding experience.

Per

Hey Tom, I have a couple of questions pertains to shaft length: I play my 5 iron at 37” and 1/2 inc. I struggle with the long irons and fairway woods probably to to my quick tempo and sudden change in direction. I love them775 hybrids as they are the only hybrids that can be bent to 3 flat. My question is for a fairway wood…What length and shaft would you recommend as in my hybrids I have the s2s black 95 regular and love them..Also, would you recommend the same shaft in my driver as currently play it at… Read more »

Eric Length in the driver and fairway woods is not determined by your height or wrist to floor dimension or your iron length. Driver and wood length is determined by your ability AND your swing characteristics. The general proviso on that is the more the golfer struggles with issues like accuracy and/or shot consistency, the shorter the length should be. Vice versa the smoother the swing, the more controlled the swing, the less the golfer had issues with accuracy and consistency, the longer the woods COULD be, not should be. In general I am of the opinoin that the industry… Read more »

Thank you Tom for your feedback as it is greatly appreciated…Along the same lines, I just purchased your 5 hybrid to match the 3 and 4 I already have. By the way, I love the way they feel…With that said, I built it to 37 inches because I played my 5 iron at 37” and could not find a way to get the head weight back nor the feel. I used a tip weight and also added weight to the port and could only achieve C4 SW. I have also ordered a 25g grip so hopefully I can get back… Read more »

ERIC On thee 5 hybrid, there are two weight bores in the head, one in the base of the hosel at the bottom of the shafting bore, and the second one on the toe side of the sole, covered by the small oval shaped TW logo medallion. Both those two can accept up to a 9g tungsten weight so with both you can add 18g to the head before having to go with a tip weight. From my calculations at 37″ with a 75g weight shaft and 50g grip, filling both weight bores with a 9g weight each should get… Read more »

Thanks so much for this information, greatly appreciated. Eric

Eric, I would consider playing the 775 # 5 hybrid at 37.5 i.e. -1/2 inch from Tom’s intended length for this Hybrid’s spec head weight. Taking full advantage of the added 18 grams total to the weight ports this should achieve a D0.8 swing weight. While going to a 25 gram grip is certainly a viable part of the solution it will restrict your choices of grips.

Hi, can the 775HS Hybid be bored to accept a .355 shaft? If it can would Diamond International provide this service for a fee prior to shipment. Thanks.

RAY

Yes of course, the 775 can be reamed to accept a 0.355 tapered shaft. This is a fairly rare request because most that want the hybrid bore changed want it to be 0.370. But I am sure they can do it and you just need to ask when you place the order for the head.

TOM

Tom, thanks for your reply. Are there thoughts of future hybrids being designed at .370?

RAY No, I can tell you that I will likely never change from using a 0.335 bore in my hybrid designs. The reason is because I have found that I can design much better performing hybrid shafts for different levels of players by using a 0.335 tip construction in the shafts’ design. This goes way back to the summer before we opened Wishon Golf when I was finalizing all the designs for the first year product line. Originally I did design our first generation hybrid shafts with a 0.370 tip because I wanted the hybrids to be considered part of… Read more »

Tom, with the advancement of shaft technology and the ability to adjust shaft profile to suit different player/swing types I would think .370 shafts could be designed to match any characteristics designed into .335 shafts. Looking at shafts available through Golfworks there are no listings for .335 hybrid shafts thus limiting options to your shaft offerings. Would .335 fairway shafts generally be a viable option for your hybrids? If one were to bore out your hybrids to .370 what weight loss should one expect? Thanks.

BILL: It sounds like you may not be familiar with the fact that I have designed all of the Wishon shafts in both steel and graphite and have done that as part of the Wishon product line since 2003 when we first debuted the brand and its models. Way back in 2002 when I was finishing up all the new models for year one of the company, I had tried to design my hybrid heads with a 0.370 bore to accept any parallel tip iron shaft. I was convinced that hybrids needed to be thought of as low loft iron… Read more »

Tom, thanks for your reply detailing your experience in designing your shafts and reasoning for not pivoting to .370 hosel sizing for your hybrids. My question on possible hybrids in future being designed with a .370 hosel was my experience with a particular .370 shaft which I would like to use in your 775HS hybrid. If I were to convert this hybrid to .370 what should I expect for weight loss? Thanks.

Bill;

The weight loss from reaming from 0.335 to 0.370 is negligible, not more than a gram or so, if that. Keep in mind that an increase from 0.335 to 0.370 means you are removing only 0.0075″ of actual material from the inside walls of the hosel. You can’t even hold your index finger and thumb that closely apart, it is so small. So the mass loss is totally insignificant.

TOM

Tom, thanks. I expected a greater weight loss so that is good- i will take a closer look at your shaft offerings for your 775 Hybrids before boring to .370.

I am building a set of 575mmc irons with the PCF Micro Pro wedges. The FC 80 Steel Fiber .370 shafts tipping chart recommends that the PW be tipped at 4 7/8 ” I believe, But no tipping for the 52,56 60 wedges. Could you please advise me on how much the wedges should be tipped?

Bobby

I have never seen a situation where the gap wedge, sand wedge and lob wedge tip trims for a shaft are zero when the PW is more normal at 4+ inches. Only if the shafts for the wedges were specifically DIFFERENT and made ONLY for the wedges would that possibly be true. 99% of the time all the wedges for the same shaft would be tip trimmed the same. Best to double check with the maker of the shafts to get this clarified before you start cutting.

TOM

I have a set of these hybrids. I remember back in the day that you could tip a wood steel shaft to match the irons. I currently play Nippon 950GH S and would like to put the same shaft in them. Any ideas to tip these to match my irons.

BILL: As long as the tip diameter of the wood shaft matched the bore diameter of the hybrid it is possible to use a wood shaft in a hybrid. Now that being said, it is no small challenge to try to figure out how much to tip the wood shaft because factors like the shafts actual stiffness progression and tip parallel length come into the picture to cloud things. In the end it really is much better to find a hybrid shaft that fits your swing than to be working in the clouds trying to guess how to trim a… Read more »

Hi Tom,

I currently play the Sterling Irons including the Sterling 5h.

I’m thinking of having some 775’s built as single length clubs at 39.5 or 40 inches in length.

My swing speed with my irons is approximately 80-85 mph.

If I have the 4h 775 built to this length is it likely to generate more distance than the Sterling 5h.

Would I have enough swing speed to generate good distance with the 2/3 775h at this length.

Peter: There is a custom clubmaker in Canada who has done very well making a single length hybrid set from the 775 hybrid heads. The fact that the heads have two weight bores helps tremendously for achieving matched swingweights when the hybrids are all made to one length. He tells us he has good success with this. There is absolutely no question that a 775-4 hybrid made to 39, 39.5, 40 inches would hit the ball longer than the Sterling #5 hybrid. The reason is because of the big length difference between 39-40 and back down to the 36.5 or… Read more »

Good Morning Mr. Wishon

I applied for a account with Diamond Golf about a month ago. Mr. Gale left me a message on my cell phone regarding my application indicating that I was accepted and a Mr. Jason Nichols would be contacting me with more information. I have left emails and a couple of phone calls letting them no that no one has gotten back to me. If there is anything you can do to complete my process I would appreciate it. Thank you

BOBBY

I asked Jason to respond and I see that he did that within 2 minutes of my asking. So I trust this is being taken care of and I do thank you very much for both your interest in us and in your taking the time to contact us when you did not hear back sooner. Sorry about that and the guys will learn from this for the future.

Thanks again and the very best to you in this great game,

TOM

Hi my Three and four 775 Hs face is peeling? No one seems to be able to help.Spoke to a very nice person on telephone from England.Have not been able to get back.Just want to see how I can go about replacing the heads.Would also like to order five and six hybrid.thank you.willie

Mr. Payne: Call Diamond Golf at 1-844-552-3437 and ask for a customer service agent named Alison. Tell her I told you to call her to report this plating defect on one of the 775HS heads and let her take it from there. Please understand that they can only credit or replace heads for the clubmaker that ordered the heads. So if you are the golfer who bought the club from a clubmaker, then you need to take the club to the clubmaker and have him contact Alison to do the replacement. She can probably also help you with the other… Read more »