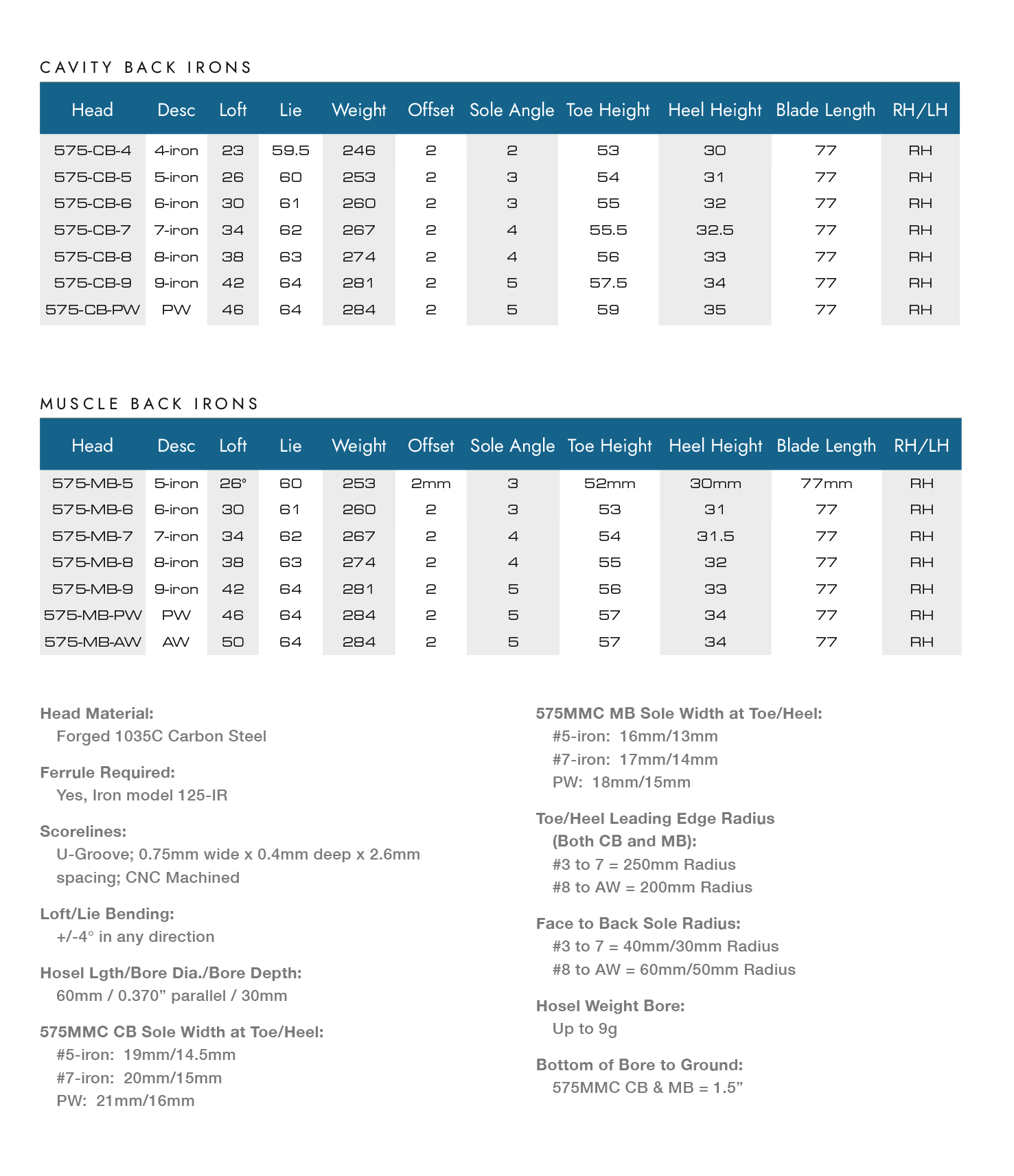

575MMC FORGED IRONS

Progressive Cavity Back and Muscle Back Forged Designs with each Back Design formed by CNC Machining…

Features:

-

-

Progressive CNC machined 575MMC cavity back created in a full, #4 to 9, PW, AW set makeup

-

Progressive cavity back design moves weight from lower on the long irons to higher on the short irons

-

Progressive CNC machined 575MMC muscle back designed in a #5 to 9, PW, AW set makeup

-

Progressive milled muscleback design moves weight higher on the back through the wedges

-

575MMC set expansion allows each version to be played as a full set or in mix and match set makeup option

-

More compact head size with shorter blade length offers the compact look in the playing position desired by more traditional minded players

-

All new CNC machining pattern results in a beautiful milled surface finish – a truly unique look to match the solid feel of a soft 1035C carbon steel forged iron design

-

CNC machined scorelines under 2010 USGA and R & A rule guidelines

-

© COPYRIGHT 2025 WISHON GOLF

I love the design of this club, sadly I doubt I would be able to play it. 17 hcp

Tom,

Went passed and visited Bob Howe here in Perth Australia.

Looking to get the combo set of 575MMC (blades and cavity backs)He said they no longer available as combo set and only available in cavity backs – is that correct?

Craig When the new 585 forged irons were introduced, we knew that with us also still having the 565MC forged irons that we really could not support three separate forged iron models. So since the 565 are designed for a different player type than the 575 or 585, we decided to gradually bow out of the 575. The plan eventually for the 585 will be to extend the cavity portion of the set so that one of these days it would be possible to order and play a full cavity version of the 585 or a mixed set with the… Read more »

Hi Tom,

would be possible to design any forged and SL irons ?

Sorry i did no read all the questions… already asked.

Richard Of course it is possible to design a single length iron set as a forging. But every clubhead that is designed has to have one big reason for existance – it has to be able to sell well enough to justify the expenses in development, tooling and inventory. And that is where a forged single length iron set falls well short. Tooling costs to prepare for production are 10 times higher than for an investment cast model. Production costs are twice as expensive for a forging as for an investment cast iron. And the demand among golfer for an… Read more »

Hi Tom

I managed to pick up a mint set of 575MMC Forged irons. My first ever Wishon irons.

love the softe feel and sound at impact.

As i have been used to jacked up stronger lofts on my previous irons…if i alter the 575 to slightly stronger lofts will it impact turf interaction ?

Thank you

steven

Steven Owing to the traditional player types that they are typically aimed at, forged carbon steel irons rarely ever are designed with lofts lower than a 26* #5 iron, graduating in 4* increments up to a 48* #PW. That’s the loft design of the 575s. They can be bent stronger, but if you push the loft more than 2* lower on each head, the heads start to look more offset and the lower number irons that always are designed with less bounce, can end up being ever so slightly a scoop/digger sole. You can bend them all lower by 1*… Read more »

Just revisiting the site. I got fitted for my 575s in 2012 and they’re still going strong. I love them and think they look great and perform immaculately. I also love the fact that you respond to people’s queries so well Tom. It’s great to see people getting straight answers without the marketing and hype. 👍

Codax Thanks, helping people with the right information has ALWAYS been a major focus for me all through my career. It goes WAY back to when I first started to get hooked on equipment. I’d keep trying to call industry people to ask tech questions and constantly got put off so one day I got really mad and made a pledge that I would figure this stuff out on my own and when I did, I would always share anything I learned along the way with anyone that was interested. Thanks much and wow, sometimes I forget how long some… Read more »

Tom, is there a handicap range that your new 585PC irons target?

RAY Yeah, good question for sure. I would aim the new 585 forge irons at an avg handicap range of say, scratch to 10. Maybe scratch to 8. While the progressive cavity from the #4 to 7 will help players who are not reallyt good ball strikers, it still is not a super deep cavity so off center hits are not going to be covered up as well as what the 565 in a forging can offer. I see the 565s as for a range from say, scratch to 16 or so. But the 585s are not designed for that… Read more »

Hi Tom

I heard the 575mmc is about to be discontinued. Is this true? If so, will there be an equivalent forged iron coming soon?

Johan No, the 575 is remaining in the product line. We are introducing a new forged iron in the next few days, which is called the 585. Information and photos on it should be up on the website within a week because I just sent Diamond the written copy for the presentation. I think it may be the most beautiful forged iron I have ever designed. But then, I am a little bit prejudiced so you’ll have to see it in your hands to determine if you agree! HA! We will keep the 575 but if the 585 starts to… Read more »

Can’t wait to see the photos of the new iron! 575 is the most beautiful iron I’ve seen so let’s see if it gets “beaten”.

Any other new designs on the way?

JOHAN I will be interested to hear if you do think the new 585 is better looking than the 575. Remember – both the 575 and 585 are completely CNC Milled for their back designs from a raw blank back forging. Since the creation of the 575, we have learned a lot more about using CNC machining to carve out the entire back design, both from a weight distribution standpoint as well as from a cosmetic standpoint. That’s why I think the new 585 would win the comparison, but I will be interested in hearing what you think. Other new… Read more »

Wow! I can’t wait to check them out! I just bought a full bag of Wishon 2 years ago. My wife won’t be happy if I buy more…:)

Tom, from the photos I have seen I have no doubt the 585 will be the best iron you have produced in the looks department and it goes without saying the performance will match if not out perform any iron from the OEM manufacturers with their crazy (meaningless) specific iron lofts. Your new offerings have created excitement for me for sure.

Joe

Thank you very much Joe, for the very kind words. If nothing else, over the past year or two I have had the chance to be more “prolific” in my design work than for any time of the Wishon Golf brand. By the end of the year there should be 2 new drivers, 2 new sets of fwy woods, 2 new sets of hybrids, 2 new wedge families and new graphite shafts for woods, hybrids and possibly irons. And what the heck, in between all that design work I managed to sandwich in an open heart surgery to correct a… Read more »

Tom, in addition to all that you have accomplished, you also wrote your great book Cap’n Clubmaker for which I am long overdue in telling you how much I enjoyed it and continue to enjoy it. Although I have never built clubs every once in a while I go back to look up things that come up in regards club making and/or fitting. Finally, I had a set of Sterlings built by a clubmaker locally two summers ago and I can’t tell you excited he is about your new clubs designs coming soon. One last question I have for when… Read more »

JOE THanks so much for your kind words about the Capn Clubmaker book. I truly do appreciate that and am pleased to know you enjoyed the material in the book. I can say it was a lot of fun to write it, both for the chance to revisit many of the fun and interesting experiences I have had, as well as to be able to pull all the information together of the practical side of what I have learned in my many years of work with golf clubs. With regard to your question about senior steel iron shafts, I am… Read more »

Take good care of yourself, Tom, the industry needs people like you.

Tom I think I saw the new 585 in an online forum and they look great! I like the flow of cavity to blade through the set. Will they be available so you can choose where the switch from cavity to blade is? I might prefer the 575 though, because I love the shiny steel 🙂 But im sure I’ll be testning out the 585. I’ve been struggling a bit with my 4 iron. Would you say the 585 is more forgiving? I also saw the 719 driver. That’s a looker! How is it different to the 919? I’m really… Read more »

Johan Thanks for the kind words on the new 585 forged iron model. Intially the set is #4, 5, 6, 7 in the progressive cavity back followed by #8-AW in the progressive muscleback. So for now this is the set makeup and there is not yet the ability to choose how many cavity backs and how many musclebacks one would want in their set. If the model is received positively by the clubmaker market, then the plan would be to finish off the cavity backs for #8, 9, P, A but leave the musclebacks at #8-AW. So if we are… Read more »

I think the 585 look great. Remind me of the Macgregor VIPs I played in college.

But, I still find the 575 MB to be MORE eye-catching!

ROD

Thanks very much for your post and your opinion. I thought the new type of plating on the 585s was pretty special and combined with the new milling procedures the foundry has developed for the backs of my type of forged cavity back construction design, combined to make the 585s pretty nice. But since the 575s are one of my “kids” too, I’ll agree with you that the 575 looks pretty good too! Thanks much and the best to you in this great game,

TOM

Hi, Tom. You said previously that, “there are deep cavity back non offset irons out there.” Do you offer one? If not, are you developing one? Thanks.

JJ Yes for sure. First off, low offset is considered in my book as being offset of 2mm or less. The 565 forged irons are a deep cavity back with 2mm offset. The EQ1 are hollow irons so that really is the same thing MOI wise as a deep cavity back because the whole inside of the head is hollow, so most all the mass is positioned on the perimeter as it is in a deep cavity back – the EQ1 irons are all 2mm offset. The 989CLA irons are a deep cavity back, all with a 2mm offset. So… Read more »

Hi Tom, I’m looking to try some new irons, and I’ve seen a good used set of your 575mmc irons with the stepless wishon S flex shaft… I currently play with rifle (project X 6.0) shafts.

Quick question… How do your shafts play compared to the rifles?

BOB Sorry for the delay in responding. Somehow your post was slotted into a different area that doesn’t get looked at all that often. SORRY!! I am not sure if you are aware that we lost our source for the production of the Stepless and Superlite steel iron shafts that had been a mainstay in our shaft design line for many years. A victim of Covid. But if you have found a clubmaker who had some Stepless shafts in his shop that you are considering for use with the 575s, I can say for sure if you have liked the… Read more »

Sir, just a quick question unrelated. Played Pennick blades for 30 years. Just recently switched to M2s. Pulling my long irons left or low right and short. Is that because of a difference in bottom edge

Patrick How about that!! I designed the Penick like of clubs back in 1994-95 – you don’t hear much about the clubs because the product line only lasted through about 1996-7. That’s incredible you have a set of the irons. Anyway, on to trying to help you. There are a few reasons why golfers may pull the ball with irons. Since I can’t see you swing to nail anything down, I will list the primary reasons and you can sort through them one by one to see what might help. 1) If the lie of the new irons is too… Read more »

Tom,

How does one choose between the 575 cavity back and the 565? I am working my way down to single digit handicap with my swing change (much shorter backswing, connected right elbow) and am now hitting a standard draw versus my old over-the-top fade.

I’ve always played Mizuno forged irons and love the feel. I have a good fitter nearby in Anthony Wright.

Thanks!

Brian Many thanks for your interest. The biggest point of selection between the 575 and 565 is the size. The 575 is more of a compact size forging while the 565 as a larger size head, approaches the size of many medium high game improvement models out there. That being said, no traditionalist I have heard from considers the 565 too large. Most players used to a forged cavity back from other companies would be ok with the size increase of the 565. I did that intentionally to add to the larger, deeper back cavity to push the MOI and… Read more »

Hi Tom, I hope you and your family are well in such uncertain times. Thank goodness for golf and clubmaking. I have started to build some sets using MOI matching but am interested in considering the variable of MOI Balance Index. This was apparently designed by Monte Doherty but the excel file is not available on the internet. Do you have any way this can be approximately calculated or have access to the file. I am off course happy to pay for this file but cannot find it anywhere. The theory of MOI balance index reflects my experience with MOI… Read more »

George Thanks very much for your kind thoughts and I do hope you and your family are weathering the continued storm of the pandemic as well. Since I work solo in my workshop where no one ever visits, in my semi retirement consulting position for Diamond Golf, I have always worked REMOTELY (!!) so I never had to worry much about masks and social distancing at least during the work day! I am sorry but I do not have Monte’s MBI file. I think if you joined the AGCP that would put you on their clubmaker forum where quite a… Read more »

All the way from sunny South Africa. I have had a set of 575 MMC Forged which ive used for the past 2 years, and oh my, if I ever had to replace them, I would get Wishon again. Absolutely magnificent irons! A job magnificently well done on these!

Pieter

Thank you so much for taking the time to stop by and share your experience with the 575 forged irons. It truly is my pleasure and an honor to know that you play with and like one of my designs, all the way down there in South Africa. Thank you very much and the very best to you in this great game! (As a little hint, add 10 to the model number of your irons and wait until early next year and you might just see something that could make you think about possibly retiring the 575s!!)

TOM ;>)

Hi Tom, Buying a set of the 575mb and noticed there isn’t a 3 or 4 iron option. My club builder said there was a 4 iron MB option. Is he wrong? Really need a 3 and 4 iron mb. Can’t stand cavity backs as I work the ball a great deal and hardly ever miss the center of the face. I hit the 7iron at 35.5 loft, 63.5 lie and 36.75 length with KBS 130x spined at d4 swingweight that club builder made for me. Excellent club. Great feel and workability. Gained a club and a half. Really would… Read more »

Michael Many thanks for your interest! I’m pleased to hear that you like the 575 irons that you have tried so far. We were the first to incorporate a 5 step forging process over the previous 4 step that was the only way forged irons were made in the past. A few other companies have now followed our lead and changed to a 5 step process because if done right with the right press and force, the 5th step can eliminate a huge number of the small internal voids which can change the impact feel by reducing the internal vibrations… Read more »

Hi Tom, Thanks for the reply and sorry for delayed response. Sad to hear about 3 and 4 irons. I really like to work the ball into greens from 190-220 out due to the descending angle being shallower causing more roll out. Especially on hard greens. If pin is middle right I hit a fade that falls right and rolls toward flag. Much easier to accomplish with a MB. I tried the 4 in CB but can’t work it. It does fly higher and descends steeper but still can’t get the curve needed. I know it’s a shot in the… Read more »

Michael I am sorry that we can’t help you with an actual blade long iron. Even from day one of the 575s we knew there would never be enough demand for a 3, 4 iron in the MB version so none were ever tooled and made. From day one we started the MB version at #5, figuring those who wanted to go 5-wedges with the MB would use the CB for the 3 or 4. I am also sorry that you cannot seem to get the shot pattern from the CB that you desire. In 35 yrs of designing and… Read more »

No worries. The 4 iron just goes dead straight. Can’t for the life of me work it one way or the other. It might be the shaft. I switched to KBS Tour 130 x from DG TI X100. The stiffer tip section might be the issue. I’m probably switching back to x100. I put the 9 iron head into a x100 today. Boy does the iron head feel great. Super soft. I couldn’t get that feeling with the KBS at all. The only problem is the SW is like D9 in x100. In KBS it is D6. The head weighs… Read more »

Michael Perhaps the best proof I can offer that forged cavity back irons can be used to work the ball is to look at how many tour pros play with all sorts of different cavity back irons from shallow to deep cavity, from carbon to stainless steel. There is no way a tour player would use a cavity back if he were unable to hit intentional draws and fades, high and low shots whenever he needed to. Among all the ways it can be done you have not said how exactly you go about working the ball – grip change,… Read more »

Tom I can’t thank you enough for these fantastic irons! First new set I’ve had since your 1995 Harvey Penick design. Absolutely beautiful and oh soooo straight! Both on the course, and with a launch monitor, I’m within 3′ of my target line. I’ve always been accurate, but Sir your clubs have moved me to an entirely new level. John Gamble at Charlotte Golf MFG did the superb fitting. Thank you!

AMY Wow, thanks so much for taking the time to share your experience with the 575s and John Gamble. Without question you did right in choosing to work with John cuz he really is one of the best clubmakers in the whole country. And to think the 575s replaced a set of the original HP’s is pretty special for me to think about too!! I have a couple photos of me with Harvey close to my desk area that I look at every day and remember what a special time that was for me to be able to get to… Read more »

Hey Tom, I do like to troll around your Q&A on here from time to time. Its really informative and wonderful you take the time to give such quality answers to the many golfers and fitters on here. You’ve said it before that the club head is the engine of the golf club and that swingweight/moi is an “A” effect fitting specification from “distance” to “feel.” Of course the shaft can change the sw/moi the most, but the head is still the engine! Ever thought of doing a forged “player” version of the 989CLA? I think is would pretty darn… Read more »

Nathan Thanks very much for your interest in digging around the various topics to pick up information to help you more with your understanding about golf clubs. I’ve hated misinformation from day one of my career so I have tried hard to make it a point to share the most truthful, factual information that I can, from all my work. That’s a good point about a player’s iron that could offer a wider range in weight addition to the head. I will think about that. But I do have to add that over the many years of evaluating specific player… Read more »

Hi Tom – I’ve had both a driver and 60 degree wedge from you and they are by a mile the best clubs in my bag. However I have a question on which I think your expert opinion would be excellent. I’m a mid-handicap golfer (i.e. 18) and am looking to get it lower, would you recommend investing in I forged irons at this stage or remain with the cast “game improvement irons”? I’ve heard that I may lose an element of forgiveness on the forged irons, however I feel for my game to get into the single digits I… Read more »

Matt: Thanks very much for your very kind words about the driver and wedge – I am very pleased to hear they are performing well for you! (Actually I do have a talk with all of my “kids” before they leave home to go live with their new “friends”!!! HA! OK, now I am going to be blunt and completely honest. There have been far, far, FAR more golfers hurt by making a change to the typical type of forged irons than have ever been helped. Golf is a hard game. No one but the best hit the majority of… Read more »

To be a little blunt, there is no reason switching to a blade would make your handicap lower. I’ve been between a +1 and +3 handicap wise the last few years and I still play game improvement irons. I rarely mis hit my shots but the few times I do or the days I’m a little off I’m getting away with my misses where I wouldn’t with traditional blades. I can shape my cavity irons just as well as I could with blades. I think it would be smarter to look at whats in the LPGA players bags vs the… Read more »

Hi Tom – really enjoy your answers to questions very informative and non biased …keep it up ! A couple of questions for you if you wouldn’t mind providing your expert opinion on. 1 – I have been experimenting with driver length have and have seen some small gains in longer shafts playing around 47 inches, whats your thoughts on this. 2 – I have oddly noticed i am hitting x type shafts farther than R type shafts but my driver swing speed is only max around 95 – 98, is there something to how i am loading the shaft… Read more »

WAYNE My pleasure to help with any answers and information you seek. The only golfers that I could possibly see in a 47″ long driver would be those who have the following swing characteristics – SMOOOTH TEMPO (definitely not aggressive or like a real “hitter”), Flatter to normal swing plane (definitely not an upright swing plane), inside out to square swing path (definitely NOT outside in with the path), and a later to very late release of the wrist-hinge angle coming into impact. If that’s not you, then over time you can expect the 47″ length to cause many more… Read more »

Hi Tom. I’m hoping there might be a solution to getting hold of an extremely flat lie golf iron: 9 degrees!! (Based on a STD lie of a Srixon iron. I’m afraid I’m not sure what their STD is but wanted to ask the question first) A scratch golfer student of mine hits the ball very solidly but always fights a hook so is constantly working on holding off his shots. His current irons are Srixon forged and 2 degrees flat. He has a GC Quad and the data shows that at impact the toe is up by 7 degrees… Read more »

Nick I really do not think I would trust any launch monitor to reveal what a player’s lie angle should be. Especially not when there is a completely fool proof science based method of checking the lie angle for a player at impact. So ignore what the launch monitor says about the toe being 7* up and do this test several times with different clubs. . . . . With a Sharpie pen, put a thick, straight line on the ball, about an inch long. Tee up the ball like you would on a par 3 hole with the ink… Read more »

Thanks so much for the response and help Tom. It turns out that the dots on the club face had not been placed accurately enough resulting in very inaccurate results from the GC Quad. When the Sharpie test was done, the lie angle is spot on!

If his lie angle is 2 degrees flat and he currently uses a Taylormade M5 driver, would there be a significant difference if he were to use one of your driver’s with the adjusted lie angle?

NICK Of all the clubheads in the bag, lie is the least important with the driver and most important with the irons, especially the higher loft irons and wedges. The reason lie is not all that big of a deal with the driver is because the driver has the lowest loft. And conversely the reason lie is so important with the irons and wedges is because as the loft increases, the misdirection angle of the shot coming off the face when the clubhead comes to impact toe up or heel up is greatly magnified by the higher loft. Also, the… Read more »

Thanks again Tom for such a detailed and well explained answer. You have made things a lot clearer. Will check lie angle of driver to see where we’re at and go from there.

Is it possible to achieve a single length iron set with muscleback heads, or is a lot of the technology in making variations within the head designs what allows single length irons to work. Ie making the head adjustments so that you get proper ball trajectory, backspin and speed with a PW as you do with a 4i

Gregory The first key element in adapting any iron design style into a single length model is to design all the iron heads with the same head weight. That’s a must so all the irons can end up with the same swingweight or same MOI once they are all cut to the same length. This is why it is impossible to adapt a conventional iron set to be re assembled into a single length set. But the other key element is what will be the golfer’s lowest number iron in the single length set so all the irons can still… Read more »

Tom,

email I received from Diamond Golf.

Hello Dennis, The TW575C-AW option is a closed out option and we unfortunately no longer hold stock. The TW575C-3 is also closed out. With Kind Regards, Alison Diamond Golf/Wishon Golf.

I am having a AW in the MB replace the CB.

Tom,

Thank you for getting back to me, I really appreciate it. I’m picking up the 5 thru PW today and can’t wait to hit them. Tim Mosel out of Denville NJ does an excellent job. I will talk to him about the AW, he must of received wrong information.

Thanks again,

Dennis

Dennis Looks like I was wrong, said with a level of embarrassment!!! VERY sorry about that, just goes to show that I am isolated over here working on the new stuff for the line and not sticking my nose in to find out what’s up here and there. But as they said, the AW in the MB version of the 575 would be fine because at that loft, the heel toe weighting of the cavity back is not nearly as effective for off center hit forgiveness as it is in the lower lofts. So you could play the AW in… Read more »

Hi Tom,

Always a pleasure to listen to what you have to say about club designs. In this regard, what is your opinions/ views of the new Srixon ZX7 irons’ heel-relief grind and V-sole design?

Are these designs and grinds really functional or simply marketing hype? Curious about your views on those. Thanks.

Wilson Thanks so much for your interest too!! I’m always happy to comment on new designs from all the years of design and research experience I have acquired over the many years I have been doing this stuff! One of the most interesting things that golfers tend to not think about when viewing variations in sole designs on irons is that when you hit the ball properly, the head hits the ball first, before the sole ever makes contact with the ground. Anytime you hit a shot that is not “fat”, the face hits the ball and the ball is… Read more »

Hi Tom, Amazing knowledge and thank you so much for your views on the sole designs and grinds, much appreciated indeed! Yes I can imagine that, as long as the shot is not fat or with shallower AoA, such sole designs are more of a psychological comfort or visual. If going down on this topic, what are the true ground-interaction effects of wider soles compared to narrower ones besides the fact that wider soles have more weight distributed further back of the face and thus would have higher MOI, forgiveness, and higher trajectory, e.g. cavity/ game improvement irons versus, say,… Read more »

Wilson Ground interaction is a product of what we call the effective bounce combined of course with the condition of the ground – firm, soft, etc. Effective bounce is actually how far up off the ground is the leading edge when you put the wedge into the playing position? As the sole gets wider, the leading edge rises up more because with any bounce, the point of contact of the sole to the ground is the TRAILING BACK EDGE. So as the sole gets wider with bounce on it, the leading edge rises up higher and higher off the ground.… Read more »

Hi Tom, Much appreciated for your knowledge and expertise, as always. In terms of lower CG for blades, I think that major OEMs have been propagating misleading concepts all these years though. By the same token, I also start to wonder whether or not technologies such as J* Break and various compression channels on metal woods really add any rebound effect and thus ball speed. Likewise, some boutique Japanese irons have extra milling patterns on the face (just like most wedges) — thus in theory stops quicker with higher spins. Anyway, golf industry is huge so it is common to… Read more »

WILSON The big golf companies tend to exaggerate the effect of whatever new technology they put on their latest design. They also mislead golfers with their claims. The J**L Break bars firm up the front body area of the head so it can change the impact FEEL but the COR is the COR. In short, you can make a 0.830 COR driver without the J Break bars just as you can make a 0.830 COR with them. They really do not add anything to the performance that is not already there in driver face and head design. But it looks… Read more »

Ha ha, golf is a game of honesty — but the golf industry is not. The aerodynamic example you raised perfectly shows that major OEMs’ bottom line is more important than true technology benefit/ advance of the club to the shareholders. They try to to elevate the entire product profile by adopting auto industry’s wind tunnel drag design — totally ignoring the fact that such cd (coefficient of drag) only works at high speeds (this applies to golf swing though) and in a straight line. The drag would be all over the place if the car is spinning around. Then… Read more »

Wilson I can’t answer for any of the companies that choose to put grooves or a milling pattern on the face of a driver. On one hand it is said that less spin on the driver is optimal. On the other hand, a driver has to generate a certain amount of spin or else the ball cannot stay in the air as long. Most people who generate too much spin with a driver such that the ball flight is far less than optimal do that because of swing errors that are so bad that nothing you do with the club… Read more »

Thanks for the facts, Tom, as always! Since truth been told, I do sincerely look forward to further continuous successes of your company in the golf industry. This way, all consumer golfers would have a choice for themselves. I do wish you win a lottery though.

Best regards.

Wilson

HEY, I hope I win a lottery as well !!! Thanks very much again for your interest,

TOM ;>)

Tom,

I am having a new set of the 575MMC CB made and my builder just said that the AW was discontinued. Why and how I am going to replace it as it was my 50 degree and your wedges start at 52.

Dennis I doubt that the 575CB AW heads are discontinued. If Diamond Golf does not have any right now it is because they are out of stock due to this absolutely unbelievable state that all the production factories are in due to the HUGE boom in golf that has begun to happen because of the effect of COVID pandemic on people’s activity habits. I am here in the States while all of the Diamond Golf folks are over in the UK and while I communicate daily with them on things that I do for them and the Wishon Golf brand,… Read more »

Tom,

I was going to have a set of Irons made with the 575MMC MB but I saw an article that said the iron set should be mixed with the CB #5, thru 7 and MB #8 thru Gap Wedge. So now I am not sure what to do and why that is. I am replacing my old Wishon irons. Can you shed a little light on why the mixed bag and if that is the way I should go. Thank you.

Dennis The option for mixing models to create a custom set makeup between the cavity and muscleback versions of the 575 is simply that – an option. In no way do I ever intend for each golfer to do a mixed set between the two models. That’s one reason I created the 575CB in a full set from #3 to wedges – so the player could use all cavity backs if desired. I did not design the #3 and 4 in the muscleback simply because I knew those two heads would rarely be ordered – it takes a player with… Read more »

Hey Tom was wondering why these irons have lofts ending with a 46 degree PW or 50 degree AW but then your wedge line has 52/56/60 lofts? Seems like it would be difficult to pair your wedge line with your iron line without having to bend the clubs 2+ degrees

Kourt Because SW’s have always most typically been 56*, the wedge sets are 52/56/60 so as to keep the usual 4* increments between each wedge. Also the wedge families in my line are several years old so they reflect the traditional lofts. The 575s are also older so they reflect what traditional forged iron lofts were at the time of their design several years ago. If I do a new forging I am certain with all the move to stronger lofts I probably would drop the lofts a tad but not all the way down to what the industry is… Read more »

There is offset magic that happens to the wedges bent to +2 loft ?