Tip Soft Shaft: What Does it Mean for Your Swing?

What is meant by a “tip soft” shaft? A shaft can be designed with many variations in the distribution of its stiffness over its whole length. A tip soft shaft is one that is designed to be more flexible in the tip portion of the shaft which we define as the last 16” to 21” of the shaft. Likewise there can be any number of variations in how stiff the tip section of a shaft is designed. The reason this is done is to help golfers with different swing characteristics find the right shaft that matches best to how they release the club, i.e. when they unhinge the wrist-cock angle on the downswing.

Most typically, golfers who unhinge the wrist-cock angle early to early/midway in the downswing are better fit with tip soft shafts, while golfers who hold the wrist-cock angle until very late in the downswing are better fit with a tip stiff or tip firm shaft. Those who unhinge the wrist cock somewhere in between early and late then are typically better fit to shafts that are more what is called a tip medium design.

The terms “tip soft/tip firm/tip medium” are completely generic in their description and in no way tell you exactly HOW TIP SOFT or HOW TIP FIRM the shaft is. That’s why we created the Shaft Bend Profile Software so that clubmakers can empirically compare how much stiffer one shaft is than another, and where on the shaft from butt to center to tip the shaft is more or less stiff.

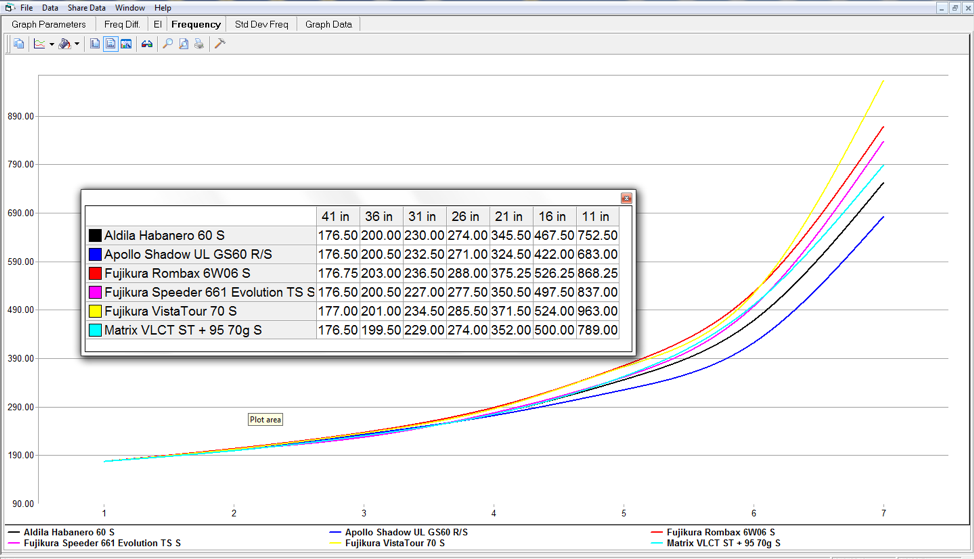

Let me explain using a graph and data from our Bend Profile Software data base. In this program we store the FULL LENGTH STIFFNESS measurements of many different shaft models and flexes so that clubmakers can empirically compare the stiffness design of one shaft to another to help them make better shaft fitting recommendations for the golfers they fit.

These are six different shafts which are designed to be virtually the same exact stiffness from the butt to the center of the shaft, but are very different in stiffness for their tip section. In the graph and data box, the 41 to 11 columns tell you WHERE the stiffness measurements were made on each shaft, in inches up from the tip end. So the 41/36 measurements are considered the BUTT end of the shaft, the 31/26 measurements the CENTER section of the shaft and the 21/16/11 considered the TIP Section of the shaft. In the measurements, the higher the number, the stiffer the shaft is at that point.

So from this you can see that the shafts are all very similar for their 41, 36, 31 measurement positions but then vary from the 26 position on down to the very tip end of the shafts. The swing speed rating of a shaft is chiefly determined by the stiffness from the 41” to the 26” measurement positions on the shaft which represent the butt to center sections of the shaft. All six of the shafts displayed in the graph could be fit to a golfer with a 90-100mph driver swing speed. The tip section stiffness among all these 90-100mph rated shafts varies from 324/422/683 (Apollo Shadow UL) all the way up to the very tip stiff design of the Fujikura Vista Tour 70-S of 371/524/963.

Thus the Apollo shaft would be fit to a golfer with a 90-100mph driver swing speed who has a very early cast-off release of the club, the Vista Tour 70 would best be for a 90-100mph driver swing speed player with a very late release of the club, and the other shafts for golfers with a 90-100mph swing speed with their release between early/midway to midway to somewhat late release.

The best way to be sure you are properly fit for the right shafts that match all your swing characteristics is to find a GOOD Clubmaker/clubfitter in your area and have them use their knowledge and experience to custom fit you.

Tom

Hi Tom, any chance you have the bend profile of the Fujikura Speeder SPD-771TA Tour Spec driver shaft stiff flex? It’s a shaft that I can barely find evidence of on the internet, but I played it for ~18yrs until my bag was stolen a yr ago. It doesn’t even appear on Fujikura’s website. Thanks in advance!

TONY I am sorry but I do not have any bend profile information on that Speeder SPD771TA shaft. I have just told Diamond that they need to be pushing more to get the shaft companies to send them their new models each year to measure and add to the data base of the shaft bend profile application that they re did a few years ago that upgraded my original bend profile software. They do need to be adding as many of the new shafts that the major shaft companies bring out each year. Not sure if that one you ask… Read more »

Tom

great info I have and old Taylormade r-7 draw driver it has a stiff 55 reax shaft with a soft tip I hit this club the most consistent of any drivers including all the new models. I’ve tried to get some specs on the shaft but have come up empty because it was discontinued. Any thoughts on something similar. I have sim2 driver with a Ventus blue 5s shaft would like to change the shaft in order to get more consistency. Thanks Jay

JASON Sorry for the delay in responding as I was trying to dig up more bend profile stiffness data from the data base we keep on shafts in the Bend Profile software program we have maintained for some time. The problem with really giving you an accurate recommendation for a shaft is that we simply never had access to any of the Reax shafts from Taylor made in that era to know what its bend profile measurements were. So if we take some liberty to assume what the butt end stiffness of that shaft was, and apply what we know… Read more »

Tom – big fan of the insight you provide. I’ve been lurking on your threads for years. My question is, since a softer butt and mid section seem to improve “feel”, what result would that profile combined with a stiff tip provide? Will the stiff tip still make it harder to close the face? Thanks.

RC Welcome and very glad to know you are out in the open now with your interest and your questions!! As you know, feel when it comes to a shaft is PURELY an individual thing, different for different golfers. It is possible that a softer butt and mid section in a shaft can make the shaft feel like it kicks a little more coming into impact for a player with a little more aggressive transition move to start the downswing. PLayers with a more aggressive start to the downswing do put more bending force on the butt and middle sections… Read more »

Such great info. Is soft tipping a shaft same as soft stepping?

Shawn To a certain extent, yes, what you call soft stepping is the same as soft tipping a shaft. Difference is that in soft stepping, you are more precise in terms of the change in the tip trim. For example, if you say “soft stepped one club” that always means you reduced the tip trim by 1/2″ (iron set). or “soft stepped 2 clubs”, you reduce the tip trim by 1 full inch. In soft tipping, there is no specific amount of tip trim reduction associated with the term. You could soften the tip trim by 1/8″, 1/4″, 1/2″, 3/4″… Read more »

Maybe a stupid question, but I haven’t been playing that long. I have a SIM Max D driver which has weight built in to help with a slice with a Fujikura Ventus Blue shaft. I’m constantly slicing, then when adjusting my grip to compensate, I start hooking the ball. A friend of mine was telling me to look into a “softer tip” shaft, but I have no idea what he means. He says it could give me a more consistent swing, naturally. I went to a fitter for my irons, but the fitter is a 4-hour drive and $$$. We… Read more »

Michael There are two ways that a driver can be made/fit so that it can reduce a slice. The absolute best and most sure way is to get a driver made with a closed/hook face angle. Perhaps you have seen drivers that when you sole them on the ground, the face points a little to the left or the hook/pull side of the fairway. A closed face angle works the best to reduce a slice because it is a degree for degree change/correction for the fact that a slice is caused by the face coming to impact open to some… Read more »

Tom, thanks so much for the insights! I just purchased a new set of irons with softer tipped shafts in them. I am a decent player (3 handicap) and have played dynamic gold for 9+ years in my irons (Taylor Made Tour Preferred MCs), I was recently fit for the new clubs and the fitter said I lose a lot of lag before impact even though my swing speed is mid 90s with irons. I am nervous about the new shafts, curious what kind of miss would I see if the shaft’s tip is too soft for me? Thanks!

BEN It is hard to accept that as a 3 hdcp your release would be early or even midway on the downswing. Most definitely low cappers can have a late-ish release and not a very late release but early to early midway seems unlikely. I say this because golfers with a later or even later midway release who also have higher than average clubhead speed (>80mph with a 7 iron) will typically see a higher ball flight when using a much softer tip shaft vs what they play. This happens because for later release players, the shaft is in a… Read more »

Tom,

I have a lot of Hogan sets and play well with both the Apex 3 and Apex 4 shaft(some of the sets are 1″ Longer than Hogan standard and these have the 4 in). In modern shafts what would you consider to be the best match to them, as those shafts are no longer available. I have always found that the True Temper Dynamic Gold to feels numb to me and flies very low. The Apex gives me a mid to high flight that tens to land softly even in the long irons.

GARY

For many years, the shaft that was closest to the old Apex steel iron shaft was the TTemper Dynalite. I think TT dropped the std Dynalite and still has the pattern available with the Dynalite Gold now. Dynalite is a softer tip shaft design than the Dynamic, which makes it closer to the Apex and also explains more why the Dynamic with its stiff tip design does not feel right to you.

TOM

Hi Tom, very interesting article. I have a set of muzuno MP 67’s Precision Rifle Flighted 6.0’s for 15 years. I have tried to change 3 times and have got PXI 6.0, Project X 6 and more recently Project X LZ 5.5’s. While all seemed to work well in the fitting I’ve struggled on the course with them missing short right. Its like I feel I can’t load the shaft. I am wondering if a softer tip shaft might be the cure, or is it mire to do with butt stiffness?

TOM Happy to hear that you enjoyed the article. It’s been an exceptionally interesting part of my career work to have been able to dig into how shafts actually perform for different golfer swing types. In general, as the golfer’s clubhead speed gets higher and as his release becomes later, the shaft’s stiffness design and distribution plays a more significant role in shot performance. For players with a slower swing speed and earlier release, the shaft’s stiffness design means very little to almost nothing to the shot. But for the players with a higher swing speed and later release especially,… Read more »

Thanks to much Tom. That is very very insightful. I’m still using the old Precision Rifle (flighted 6.0). I have the Mizuno MP 69’s with a 100 ish MPH driver swing speed. I tried the Project X 6.0 and missed short right… then tried the PXI 6.0 and the same happened. I even got the LZ 5.5 (drop a flex) and the same happened. I’m at a loss and wonder is it torque or the frequency matching as I’m stumped as to what shafts to try.

Thanks for your help.

TOM I am sorry because I would need a lot more information to be sure, but 40+ yrs of experience tells me this cannot be a shaft induced problem. If the flex or bend profile of the shaft were the cause of the short rights, it should change a little in effect as you change shafts. The fact that it is the same for all these different shafts and flexes just can’t mean IMO that the shaft’s flex would have anything to do with that. I’d look at the length, the lie, and for sure how the weighting for both… Read more »

Will anyone ever bring back this software?

BRUCE WE’re working on a total re do of the Bend Profile software as we type. BUT. . . it was always last on the to do list of new product development and then with the mess that the lockdowns and crisis has brought, it has been slowed down a bit. But I am still working on doing the measurements to build the new data base and Diamond are working with a UK programmer to rebuild the entire software based on the new guidelines we all determined it should have. When this will all come out as a brand new… Read more »

Hi Tom. Which driver shafts best match the profiles of kbs c taper shafts? C taper x have been the only shafts that worked for me. Thanks.

SEAN The C-Taper taoer tip shafts are among the stiffest iron shafts both in the butt and in the tip section of all iron shafts made. Add to that the fact they are also heavier means in a wood shaft you probably are best to look for shafts that are 80-90g in weight along with being well above average for butt and tip stiffness among all X shafts out there. Now the problem we have in actually naming shafts for you to consider is the fact that our data base of bend profile measurements of shafts is 4 going on… Read more »

Thank you, Tom. I look forward to hearing about some new shaft options in a few months. Which older shafts do you recommend? Perhaps I can look on eBay to see if they are still available. Thanks for you help. Wishing you good health

Matt I truly am sorry that somehow the website’s back end lost or mislocated your comment such that it took this long for me to find it to answer. I’ll use the 6 iron since all MOI’s of all heads in a set are a little different due to normal design differences in size and weight. The EQ1 6 iron has an MOI related to toe and heel hits of 2,985 g-cm2. To give you some comparison, a typical muscleback blade 6 iron would be around 1,790 and a typical deep cavity back iron would be around 2,650. Again, so… Read more »

Tom I need a little help. Does a stiffer tip or a softer tip driver shaft help with releasing the club head. Sometimes I can’t release the club through the ball and my launch angle gets down around 9degrees spinning at 2100 usually resulting in a mid hight draw/overdraw. Then I’ll release the club and it will launch at 14 degrees spin at 2300 and shot is a sweet piercing fade carrying about 264 and decent roll out to about 275. Will a stiffer or softer tip help me to be more consistent with my release? Obviously some of it… Read more »

ROCKY The shaft can have an effect on the release move if the golfer has a definite sense of feel for the bending feel of the shaft during the downswing and through impact. Most do not have such a perception. But for those who definitely can feel the shaft go from load to unload during the swing, the shaft most certainly can act as a point of swing timing and rhythm such that you feel the shaft load and then you feel exactly when it is time to let it go on the downswing to release the wrist hinge angle… Read more »

I am very rythem dependant on the shafts and the shaft is what I feel for in my swing to time my release. Current shaft has a unusual profile I was fitted for some 5 years ago. But I recently started working with a coach and have changed my swing a little mainly in the swallowing the club aspect which really has helped me with the release timing cause I can feel the load and unload better. The shaft is a attas elements prototype 6x Rk (radical kick) Mid launch low mid spin shaft with this new delivery I’m having… Read more »

ROCKY I sort of guessed that you would be a shaft feel timing person when I responded to your initial post and question. Four decades messing around with this stuff allows one’s 6th sense on this to develop! If you do not have the same feel with this new release move that you had before, then it is time for you to dive back into the fitting analysis to find a shaft that can demonstrate what you seek for your timing and rhythm. And if you cannot feel the shaft bending, that tends to say that the next shaft will… Read more »

Hi Tom, Just read the article on “Tip Soft Shaft – What Does It Mean for Your Swing … what a GREAT explanation for the laymen here in the field of Clubmaking. I had a couple of questions to ask of you, as 1.) My son is a golf fanatic … 9 Handicapper … hits the ball long and 80% of the time very straight. He is considering a set of single length irons and I’ve referred him to your Sterling Irons … he tells me he could not find a price, so that is my first question … How… Read more »

JOHN Always happy to help with more info! Wishon models are built and sold by custom clubmakers so because each clubmaker is independent, they set their retail prices. We can offer suggested retail pricing but under US law we cannot control what they charge for the clubs they fit and build. But in general you’d fine that the price of a set of Sterling irons would be commensurate with the price of any set of investment cast irons from any of the large golf companies which would be around $80 to $100 per iron depending on the type of shaft,… Read more »

When soft and hard stepping is there much of a difference in performance ? Also I am looking for a softer feel in my graphite and steel irons I have no problem getting the ball up in the air height wise. I was wanting to know how do you achieve in between flexes? I’m a novice club fitter on my own clubs, Thanks Ernie

ERNIE Soft and hard stepping shafts, otherwise stated as using a little more or a little less tip trim than the norm for each shaft, brings a very subtle change in flex that the majority of golfers cannot detect. Pretty much only players who have a LOT of ball striking experience, are well above average in swing and ball striking consistency, and/or above average in clubhead speed, will detect any real difference in two identical clubs which differ only in the amount of tip trim up to 1″ for the same shaft model and flex. The vast majority of players… Read more »

Yes understood thanks Tom I was wanting to experiment and achieve a softer-feel Thanks again for your useful advise .

Thanks for all your articles and info Tom, I have learned so much from your articles. This article aligns with what I have been experiencing when looking for new irons. I fight a early release and a high ball flight and have always been told to play DG s300,KBS C taper, etc to keep the ball flight down. But no matter what iron shaft you put in my hands I hit it high, not ballooning just higher than normal. I have found with the “tip soft” shafts my dispersion seems to be better, which I guess from reading you comments… Read more »

James No change in equipment with regard to the shaft will ever bring the ball down enough for you to see a distinct visible change. The early release is causing the clubhead to pass the shaft and hands coming into impact which adds loft at the moment of impact. The people who have been advising stiffer shafts or stiffer tip shafts simply do not know what they are talking about because they do not know how to look at the golf swing to evaluate this situation. Not until you work on your release to stop the clubhead from passing in… Read more »

I have a question of how to lower the torque in a shaft to a lower number. I was told that half an inch of cutting the tip relates to a certain lowering of the number of torque. Is this true or false? I bought a prgr egg bird driver 2013 with a swingweight of C3.5. Hitting this driver with a shaft length of 47 gave me trouble in fading the ball about 15 yrds. I replaced the shaft with one that has a torque of 4.8/5.1. The fading disappeared. I would like to hold on to the egg bird/fujikura… Read more »

GERARD Please understand when you change shafts in a club and you experience a good result, it is a lot of very careful work to try to determine what caused the change in the performance of the club. For example – in the club with the new shaft, was the length the same as before? Was the swingweight the same as before? Was the shaft weight the same as before? Was the entire, full length stiffness the same or different and if it was different, HOW was it different compared to the full length stiffness of the previous shaft? What… Read more »

Hi Tom,

If I understand you correctly at a 7 or 8 iron length the kick point

in the shaft and it’s effect on shot height is not significant?

So a senior shaft with a low kick point and a stiff shaft with a high kick point would yield very little difference?

If that is the case is it better to err on the less stiff lower kick point shaft for most golfers?

Thank you,

Kevin

KEVIN A shafts ability to have a VISIBLE effect on shot trajectory and spin is directly proportional to how much the shaft actually can be made to bend during the swing as it goes from “loaded” to “unloaded” coming into impact. Now, how much the shaft actually bend to do this depends entirely on all these things – 1) the higher the clubhead speed and later the release, the more the shaft can flex forward at impact to create a difference in shot height and spin. This of course depends on how stiff the shaft is to begin with in… Read more »

hello tom i have a lot of trouble finding the type of shaft im looking for the worst part of it im a fitter! i have a low spin rate with my iron and a low ball flight. i was gaming the dynalite gold xp r 300 my ball flight never got so high i got my iron stolen an this shaft is not longer available im wondering if a kbs tour r flex would be a same type of shaft? will it help me get some spin and more peak height or a pxi from project x thanks sorry… Read more »

Gabriel: I am sorry that we do not have any specific bend profile data on the Dynalite Gold XP iron shafts. We have data on the Dynalite Gold and the Dynamic Gold XP but not the Dynalite XP. but since the XP in Dynamic is very similar to the conventional Dynamic Gold, I have to believe the XP version of the Dynalite would still have the same tip section stiffness design as the conventional Dynalite Gold which is a little softer than Dynamic Gold. As such you should be looking within the standard Dynalite Gold for a replacement and not… Read more »

Tom Recently was fit for a set of ping I series, the last two shafts in the running a CFS stiff and PX6.0. Both generated consistent 120mph ball speed and similar launch profile; dispersion slightly tighter w the PX. Based on everything I’ve read above and what else I’ve read about CFS it seems this shouldn’t be the case as the two sound like they have very different characteristics…the PX mainly being stiffer in the tip section. I’m a moderate tempo 89-92mph 7i swing with what I would consider a relatively standard wrist release. How could these two measure up… Read more »

Jared: I hate to tell you this, but the reason you don’t see much difference in these shafts is because when it comes to iron shafts, there really is very little difference in terms of outright visible shot performance differences between shafts of the same flex. Shoot, with many golfers, they could use a full flex softer iron shaft and never notice any real difference. The reason is because in terms of how much iron shafts do actually bend during the swing, it is not very much – half of how much shafts in woods bend during the swing. So… Read more »

Assuming all other things being equal, what ball flight characteristics would you expect if the tip section is too soft for a golfer’s swing?

Thanks!

RON:

If the golfer has a later to very late unhinging of the wrist cock angle on the downswing, the most common characteristic of the tip section being too soft for the golfer would be a little higher ball flight combined with the golfer perhaps getting a slight sense that the shaft somehow feels a little bit more flexible than he is used to.

TOM

Re: TaylorMade RAC CGB Graphite RAC CGB ‘Soft Tip’ Regular Shaft Tom: Great, informative, article! Thank you! I have used & enjoy a set of TaylorMade RAC CGB Regular Shaft – the ‘Original’ version when the CGB’s first were released by TaylorMade. Over time, several of the hosels & shafts have been damaged. I like the feel & flight from the OEM shafts, but cannot find these shafts available from TaylorMade. Questions: 1. Is the TaylorMade RAC CGB Graphite RAC CGB ‘Soft Tip’ Regular Shaft still available through any of your sources? [It is not through the ‘Official’ TaylorMade repair… Read more »

JOE The shafts that are made for use by the OEM companies in their stock clubs are proprietary shafts to the companies and as such are not typically available to anyone outside of the company’s own repair facilities. Plus it sounds like TM no longer makes these shafts since their own repair places have them. So the only precise way to be able to find an alternative shaft that would be the same or similar would be as follows. A VERY WELL TRAINED AND EXPERIENCED clubmaker would have to remove the shaft from the longest club you have left in… Read more »

Hi Tom,

Following on from the above if I wanted to shaft the PCF Micro Tour wedges with grafite. What would be a good starting point shaft to consider?

PETER: BEcause wedges are so short in length and because the shafts installed in wedges are so typically installed with the most tip trim, it’s not going to be very likely that you would experience a feeling of the shaft in a wedge kicking more and giving you that higher flight you seek. Besides, the loft being so much higher on wedges than other irons, that on its own accounts for the higher flight anyway. So if you have decided to use the GREEN shaft in the irons, then use it in the wedges as well with its normal tip… Read more »

Thanks Tom

I think we can set up the White and the green to compare the two.

Hi Tom I am currently working through a fitting process for a set of 771 CSI’s and rather than experimenting with a wide range of shafts I would rather narrow the process down to begin with. I have a swing speed of 71-74 mph with a 6 iron. I am of a fairly average strength with a smoothish transition. I have an early to mid release. I am leaning towards a graphite shaft in a set of irons 6-gap wedge. I would like a lively shaft with a fairly high ball flight. Given these details where would you recommend me… Read more »

Peter

Given what you say about wanting a shaft that feels like it kicks a little more for your 71-74mph speed and smooth transition and early to mid release, I would say that the S2S Green may be a suitable candidate because it is a little more tip flexible than the S2S White shaft design. For your speed and transition and desire for the iron shaft to perform this way, I would tend to say the Green A flex over the R since iron shafts never bend as much as do wood shafts during the swing.

TOM

Hi, was just wondering whether the parallel tip c-taper was in the database yet? Thanks

Alex:

Yes for sure, the parallel tip version of the R, S and X flexes in the C Taper iron shaft are in the bend profile software data base. If you need any help with this, you can contact David March in our office at david@wishongolf.com. David handles everything concerning updates and downloads on that software program for us.

TOM

Tom,

I am looking for a .355 graphite shaft option to the Nippon Modus 130s. Do you happen to have data or graphite shaft suggestions comparable to Modus 130 bend profile?

Peter

I am sorry but we do not have the bend profile measurement data for the Modus 130 shafts. We’re working on other ways as we can to acquire the various shaft models that are missing from the current data base to be able to include them and thus try to keep this data base as complete as is possible. BUt for right now that doesn’t help you and I am sorry we can’t provide that info you seek.

TOM