-

The new look 919THI Driver retains the ultimate range of custom fit adaptability, designed with Wishon’s unique proprietary bendable hosel

-

Variable Thickness Face with High MOI delivers the best off centre hit performance in the game

-

All 919THI drivers undergo 6 separate face thickness QC checks during production to ensure the highest conforming smash factor

-

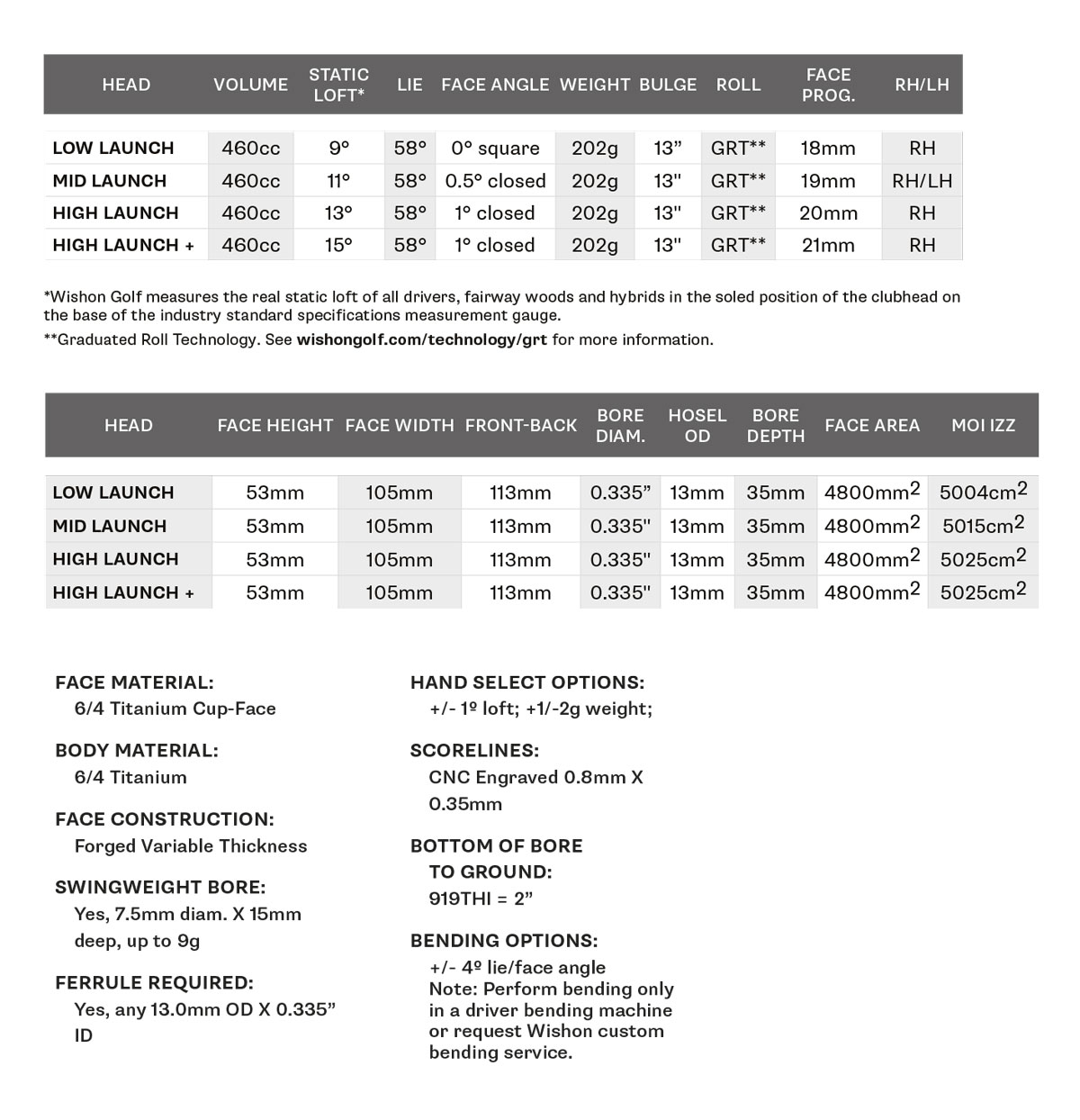

The 919THI is available in RH in Low Launch (9º), Mid Launch (11º), High Launch (13º), and High Launch+ (15º), and LH in Mid Launch (11°).

© COPYRIGHT 2024 WISHON GOLF

Hi Tom mike again I’m making a driver for a next door neighbor I play with 6-10 times a year.So Tom my man this one got to work or I’m in trouble.lol!He’s 81 has bad arthritis effecting his flexibility.He has an older ping G10 driver 10.5 degrees reg. Flex.So when on the tee especially when water is in front of him he tries to lift the ball and naturally tops it into the water.Of course this driver is totally wrong for him.I want to make him the new 919 at 14 or 15 degrees with the super lite Graffaloy 44… Read more »

MIKE At 60-65 mph swing speed, go with the highest loft 919 you can get. The High Launch PLus is a spec loft of 15.5 but you could ask for hand select to see if Diamond can find a head at 16 or even 16.5. Next, no way the driver should be longer than 43.5 to 44. And keep the swingweight low, like C2-C3 low, I kid you not. At 81 with a 60-65 swing speed, the only way he could ever merit C9 would be if he has a short backswing and then a very quick abrupt start to… Read more »

The 919THI head weighs 202g and can accommodate 9g more in the weight bore. Could additional weight be added as a tip weight to allow a shorter length assembly? I am a senior with a slow swing weight and my other Wishon clubs are around C5. Would the 730cl driver be a better choice than the 15 degree 919THI?

Ron Yes, you could use a tip weight in the 919 to be able to add more weight to the head when desired. If you put 9g in the weight bore AND you put a 9g tip weight into the end of the shaft for a total of 18g added to the head, since all that mass would be in the heel area of the head, it would move the Center of Gravity off the center plane of the face and slightly toward the heel side of the face. Golfers with a clubhead speed under 100mph would not really notice… Read more »

Hi Tom,

How are you doing? Your clubs look great. Would you be able to bend the 919THI driver so that the leading edge of the hosel is in-line with the leading edge of the face? Thanks!

Damien

Damien No, it would not be possible to bend the hosel on the 919 driver to get the leading edge at the bottom of the face in line with the front wall of the hosel. With the face progression of the 919 being at 20mm, the hosel diameter at 13mm and the hosel bore at 8.6mm, what you want would require bending the hosel over 10mm and trying to keep it parallel to the leading edge. In other words, that can’t be done. It’s too much of a bend and even if you could do it, the hosel would be… Read more »

Tom,

Could you explain the process of measuring the MOI of a driver for USGA purposes?

Thank you!

Ben First go to this page – https://www.golfmechanix.com/co/items.aspx?Pdts=07 – then scroll down until you see item #070305. That is the machine specially created to measure the various different MOIs of golf clubheads. The MOI that is outlined to define the off center hit forgiveness of a clubhead is called the MOI Izz. The Izz designation dictates the fact that the MOI Izz measurement is performed to determine the MOI about the vertical axis through the center of gravity of the head. This machine has a number of different attachments to allow a clubhead to be fixtured in a manner to… Read more »

Tom, I played your ass to S2S shaft in a driver once or twice over the years. I went ahead and ordered the 77 ones this morning and I also ordered the S2 S black graphite iron shaft with them. With my seven iron swing speed being 90 to 92 miles an hour, should I tip these shafts? I am a relatively strong person, but my transition at the top is very smooth. Even slower than Hideki Matsuyama. I come to a complete pause at the top of my swing before I start down. My hands also reach my right… Read more »

Steve Your swing speed with the 7i of 90mph with a smooth transition and not a very aggressive downswing would normally say you would not tip the Black S shafts. But that really depends on your personal SENSE OF FEEL for an iron shaft before and through impact. Some players like to feel the shaft “kick” a bit – if so, then no you don’t tip and you might even back step them one club. But if you do not want to feel the shaft bend or kick coming into impact and you prefer a firm feel at impact, then… Read more »

Tom, thank you so much for your responsiveness on this page. I am currently playing your EQ one iron set, but was considering going back to a conventional length set of irons. I’ve played both the sterling version and the EQ version and then quite happy with both, but I can’t say that I’ve seen much overall game improvement. Granted, I am a four handicap already, but really trying to get to the next level or scratch. Even at my current handicap, I know enough about my swing to know I certainly don’t always hit the dead center of the… Read more »

Steve Thanks for your interesting comments about your experience with single length irons. No question that as a 4, your shot consistency with irons is likely much better than players with higher handicaps than you. It is true that single length can have more effect on improvement for players who do have issues with shot consistency that are more than just hitting several shots in a round a little off center. Your path and face angle delivery are already consistent. Most players at 8, 15, 20, and higher handicap do exhibit ranges in their path and face angle deliver and… Read more »

Thanks Tom. That is very helpful. I will look at the 565s. I just thought the extra apparent forgiveness of the 771s would always be a plus in this difficult game. 🙂 Would you say the off center hit performance on the EQs is better – equal – or less than the 565s and 771s? Its seems like most of what you are describing are aesthetic and not necessarily performance driven. With that said, I can certainly overcome a gapping issue with loft and lie but feel, consistancy and confidence are what I am chasing. That and scratch!

Steve Off center hit forgiveness wise, I truly think that there is no other iron anywhere that can match the off center hit ball speed/forgiveness of the 771. That comes because of the variable thickness + high COR face, not the MOI from the deep cavity back. 565 is not high COR nor variable thickness so it has the MOI only to drive the off center hit forgiveness. EQ is higher COR for the 5, 6, 7 but not variable thickness so it has a tiny bit from the high COR face, with most of the forgiveness coming from the… Read more »

THNK YOU! 771 it is!

TOM :

I HAVE JUST PURCHASED A USED 919THI DRIVER 9 DEGREE. IT IS WHITE WITH A POLISHED BOTTOM. IN WATCHING YOUR VIDEO, I DON’T SEE THAT VERSION MENTIONED. JUST CURIOUS IF THERE IS SOMETHING UNIQUE ABOUT THE CLUB.

TIMOTHY

The white 919 was simply a different cosmetic version of the 919THI driver. This was back in the earlier 2010s when every company was offering a white version of their current driver model. That fad lasted perhaps 2 years before it ran its course and everyone went back to black. Although most have gone to an all black finish where the entire body is chemically treated black and then the top crown is black painted over that.

TOM

Hi Tom: I have been using the 919THI driver for a few months now and I cannot say enough good things about this club. It is by far the best driver in the market. I have even purchased a second one just in case.

TIMOTHY

Well, that’s a really nice way for me to open my “work” day, to read your kind and amazing comments!!! Thanks so much for your support and may the new member of your golfing “family” continue to behave himself for you every single day!! HA!

TOM

Hi Tom,

What is the vertical COG on the face of this driver in mm?

Thank you!

BEN The balance point on the face of the 919 driver head is 38mm up from the sole. But do keep in mind that the VERTICAL CG position in a driver is virtually meaningless because we hit the driver off a tee peg, 99.9% of the time we use the club. The tee peg combined with your swing characteristics is what controls the CG position relative to the ball at impact. With other clubs that are hit off the deck, this is where vertical CG position does have a key bearing on the launch angle and spin and shot height.… Read more »

Tom I’m considering replacing my old 919 which I’ve enjoyed very much. I’m 75 so I’m swinging about 80-85 mph my 919 is shafted with a ust dhi A flex which I really like.I’ve just started a stack and tilt swing.I’ve been at the range twice with this swing.I’m liking it it seem’s powerful to me but I had some trouble with lower pulls and hooks not unusual for me even with my old swing I’m not a slicer.Thus I’m considering getting my new 919 with 15 degree loft and have you adjust the face angle to square .Tom what… Read more »

Michael I do remember your name from previous correspondence over the years and THANK YOU so much for your support and interest since the old G-smith daze!! When it comes to shafts, I have always taken the approach that is it ain’t broke, there is no need to go out and try to fix it. You said right off in your comment that you have enjoyed the UST shaft very much. Sadly I am not familiar with the exact bend profile of this UST shaft since I have not had any of those shaft samples to do a full bend… Read more »

How much is this driver?

Many thanks

Glenn Thank you very much for your interest in the 919THI driver. All Wishon Golf designs are exclusively sold to golfers through independent custom clubmakers who fit and custom build the models for each individual golfer. No Wishon Golf designs are sold in standard, one size fits all form, as are the clubs from all the major marketed brands. The clubmakers are the ones who set the retail price based on their skills, service and overhead. Therefore we ask you to go to the link at the top of the home page on wishongolf.com for FIND A CLUBMAKER. Click on… Read more »

Hi Tom,

Should the driver be the same length as woods for a true one length setup? I’m confused how that would play, given that woods play off the ground with left of centered ball placement, and drivers play off left heel while beeing teed up. How does that work with same length clubs?

Robert No, the driver has to be considered its own separate club in the set, independent of any length decisions for single length woods. The reason is because if you chose a single length for the woods based on our recommendations of between 40-41″, the driver would be too short and would cost you distance that you wouldnot want to lose. And on the other hand, if you make the woods the same length as say a 43-44″ driver, then the woods would be much too long and too difficult to control and hit with reasonable consistency. So when looking… Read more »

Hello Tom! I love the new design of the 919 THI. I have built a “Mini bomber” at 43.5″ with a 11 deg head and Aerotech Claymore MX 60 F5 shaft. One thing I noticed is that it has a more tingy sound at imapct than the old head. This is my average numbers from indoor (Trackman). — Club Speed: 107.6 mph. AoA: 2.5 up. Ball Speed: 161 mph. Smash: 1.50. Launch Ang: 12.1 deg. Spin rate: 2246 rpm. Height: 102 ft. Carry: 271 yards Total: 295.5 yards (Longest outdoor: 319 yards). I’m very happy with the build. Kind regards… Read more »

Christher

. . . . and I am very happy with your report!!! Thanks so much for letting us know! (the only thing I am sad about is that I am old so my own clubhead speed is nowhere near your 107mph!!!!! HA!)

TOM

Haha. With a “normal length” driver (45.5″) I have a clubhead speed at 115 mph. But my misses will be severe compared to this mini bomber.

I allways has been more successful with mini drivers. Had A Aeroburner Mini driver at 12 deg and 43,5″ that I could hit long and put the ball in play.

Do you know where I can buy the molds for driver and fairway wood bending? I have one of your loft and lie machines but I can’t find the molded bending kit

Steve

The only place that can both make the molds as well as supply you with the materials to make them yourself is golfmechanix.com who are the makers of all the top club making machinery and tools in the industry. Contact the owner and lead design engineer for golf mechanic at mondher@golfmechanix.com and tell him Tom sent you. Hope this all works out well for you!

Tom

Dear Tom,

after 12+ years I am assessing to get some new gear. I was fitted by Mike McFadden in 2011 and have amongst others the 919THI (irons 560 MC, FW 929HS and hybrids 775 HS). On the internet, I found some pictures of the stunning design of the 719MW Driver. Could you indicate when the design will be available?

Best regards from Stuttgart, Germany

Marc

MARC MAny thanks for taking the time to search and find some information on the new 719MW driver design. It’s great to hear you were at Jakobsberg working with Mike for your fitting. He’s simply one of the best on the entire planet and in addition to the quality fit, you had the chance to be at a pretty nice place up above the river. It’s a really nice place and I am pleased to have been there four times myself over the years to speak at PGA educational seminars that Mike organized there. Thanks for your kind superlative on… Read more »

Thank you Tom for taking the time for your comprehensive answer. Mike is really outstanding. At the beginning, Mike didn’t want to get me a fitting and didn’t want to sell me any clubs. He said “you have got no Golf swing, you should work on this first”. But as I learned so much about golf and a good golf swing during our first meeting, I decided to become his student. So for about a year, I regularly drove from Stuttgart to Jakobsberg (2.5 hours!) to take lessons with Mike and he became my Pro. And after the third lesson… Read more »

MARC Thanks so much for sharing the story of your beginning with Mike. Wow, that is quite a commitment you made to drive that far on a regular basis! That certainly sounds like Mike from what you describe and I will be sure to share your post with him. He’s semi retired and still lives up on top of the hill very close to the Jakobsberg course, but the clubfitting business is run by his son in law Mario who studied under him for quite a few years. So I am confident that Mario is picking right up where Mike… Read more »

Tom

Thank you for your comprehensive answer re the 585. I will give them I try. I did not know that Mauricio is now running Mike’s former business. I know Mauricio as he received his PGA formation by the time I was at Jakobsberg with Mike in 2011.

All the best for you – and I hope for all of us, there a still some great designs from you to come!

Very warm regards from Stuttgart

Marc

Tom

In assembling an MOI matched set of clubs, do you recommend that the driver and fairway woods have the same MOI as the irons, or should it be different?

JIM Absolutely superb question Jim, because it would be logical to assume the driver/woods should have the same MOI as the irons. Glad you asked it so I can have a chance to answer and explain why. In a successful full MOI matching fitting experience, the driver and woods tend to be on average, 75 g-cm2 higher in MOI than what the irons are. The reason for this is because in the full set, there is usually a big gap in length between the shortest wood and the longest iron. And length is a much more influential factor in determining… Read more »

Tom

Thanks for your detailed response. One other question I have is how close in g-cm2 do the clubs need to be to be considered matched? What would the range in gm-cm2 be where one could call the clubs matched?

JIM

My pleasure. Clubs in an MOI matched set that are within 5-10 g-cm2 of each other are considered to be EXTREMELY well matched. Anything under 20 is OK, but 10-15 is really a creditable range to be in for a proper MOI matched set. I believe that no one could detect a difference of 5-10, not even a tour player because a gram-cm2 is very, very small.

TOM

Tom

The new 2023 hybrids and fairways looks great. Can’t wait to test them out!

I also read there is a new 919 and 719 driver on the way. I’m playing the current 919 so I was curious how the new drivers differ in design and performance. Always nice to hear this from the brain behind the product!

Johan The new 919THI is primarily a cosmetic upgrade to the model. The previous version had been in the line for quite a few years and we felt it was time for a makeover, so to speak! All of the performance elements and features – the variable thickness cup face construction, the bendable hosel, the shape, the OI, the CG positions, etc., are all the same as before because quite honestly, I have felt for some time that I could never design a better PERFORMING driver than the 919. So I didn’t try when it was time to do this… Read more »

And the statement above shows once again why Wishon is THE brand to go to !! Other companies would wax lyrical about how their new carbon, speed slot, jailbreak, adjustable perimeter weighting etc etc technology will add MILES to your drives (which of course, is all just marketing hype). Tom Wishon tells it as it is, fundamentally a cosmetic upgrade to a driver that is already, arguably, the best on the market bar none. If you are thinking about getting custom fit, stop thinking, find your nearest Wishon approved club fitter and make the call. I have gamed 919THI, 365… Read more »

Hi Tom,

Any updates on when the new 719MV might be available?

DAVE I am sorry but I don’t have the latest info on the delivery schedule for the 719MW driver heads. Once I finish everything in my work to design it and sign it off, the scheduling for the production and shipping is in Diamond Golf’s hands. I would recommend you call or email them directly to ask because they’ll know more about that than do I. Toll free calling from the US/Canada is 844-552-3437, from the UK is 0800 083 7388 and email is sales@wishongolf.com – as a help if you email to get to the right source, ask to… Read more »

Just a heads up, the new 719MW is now available!

Tom, I’m going to start working with Ed Ellis in a few days to custom fit driver for my bag. I have Wishon single length clubs from lob wedge to 4 wood now and find them key to my game. I’ve saved driver for last. I’m wondering if recent experience with my current TaylorMade Burner 10-degree driver and my Wishon 4 wood is helping me understand your premise about driver loft for senior players like me. My swing speed with driver is about 85-90, sometimes a bit more. I can reach 200-205 yards with my driver choked down to 43″.… Read more »

STEVE With an 85-90mph driver clubhead speed, DEPENDING ON YOUR ANGLE OF ATTACK INTO THE BALL, it should be possible to optimize your driver carry distance to be around 220-225. But as I said, that all depends on the A of A. So when you work with Ed, assuming you’ll be on a decent launch monitor, watch that A of A to see what it is. 220-225 should be possible as long as your A of A is not downward to any degree. But if you are level 0 with the A of A, a launch angle of around 14*… Read more »

Thanks for the explanation, Tom. I hit a couple practice drives this evening ending my short game practice. I paid attention to the ball flight and its apex. I topped out at about 65 feet. Carry distance was 200 and 208 yards. I’ll be curious what Ed and I figure out about my angle of attack. It’s going to be fun. Thanks again.

Steve

Steve

Yes I will be interested to hear how it goes and what Ed comes up with for you. 65 feet for a driver apex seems a bit low for your clubhead speed, in terms of max carry it is I think. But driver shot height is a trick thing because you have to gear it to the firmness/softness of the fairway. Dry, firm fairway conditions always calls for a lower launch angle and height than what would be optimal for max carry to maximize total distance. Wet, lush fairways are all about maxing carry distance. Have fun!

TOM

I’ll let you know Tom. Thanks.

Hey Tom, I’ve been using an early model (~2013) 919THI w/SP700 face for quite a while now. I’ve always been a huge fan of drivers with SP700 faces, I’m apparently one of the few golfers who can notice an appreciable difference compared to materials like 6-4 or even 15-3-3-3. Almost every driver that I’ve ever truly loved over the years, has turned out to have an SP700 face (which I often didn’t know before I fell in love with it). I’ll be honest, I wasn’t a fan of the feel/sound of the 6-4 face that the 919THI switched to back… Read more »

JAMES The only way one could tell one of the older 919s like that would be by its sole design and color. The early 919s all had a plain sole, no swoops, ledges, raised elements of any sort, and it was painted in a dark blue finish. Outside of that one would need to have a $3000 ultrasonic thickness gauge to do a face thickness measurement to tell the difference since the early SP700 faces were thinner, owing to the fact the material had a higher yield and tensile strength than 6/4 so it had to be a little thinner… Read more »

I know the first gen with the blue crown and yellow half-moon shape had an SP700 face, and that one is easily distinguishable because it looks different. But didn’t the 2nd gen also have an SP700 face for a little while? I thought the change to 6-4 happened sometime around 2015, but the 2nd gen redesign happened in around 2011. So wouldn’t any 2nd gen head from 2011-2015 have an SP700 face? But even so, you’re saying there would be no way to tell since the heads are cosmetically identical after the 6-4 face material change?

JAMES I honestly cannot tell you precisely when the change from SP700 came to 6/4 for the face of the 919. I simply cannot remember that in the face of all the many clubhead design projects and development management I have done over the many years I have been doing this. As I said in the other post, the only way to tell is with an ultrasonic thickness gauge (or by cutting the face off to do an alloy ID for the faces!!) since the SP700 face would be slightly thinner due to its higher strength. But again, the COR… Read more »

I wanted to post a follow-up comment on this, as I think I’ve identified a way to distinguish the SP700 heads to the newer 6-4 faced heads. When the 919 was first redesigned in 2011, it kept the SP700 face as well as the short hosel. Then when it was updated again in 2015 with the longer hosel, I believe that’s when the face material was changed as well. So, correct me if I’m wrong, but shouldn’t that mean any head which has the shorter hosel should also have the SP700 face? Based on my research, with the help of… Read more »

Actually, a correction to my last comment. It looks like the bendable hosel was added in late 2013, which is apparently when you also created new plasma-welding tooling dies. At that same time, the verbiage “919THI face forged from SP700 titanium” was removed from the bullet points on the product page, although in the product images which show all of the detailed specs it still said “Face Material: SP700 Titanium”. That remained until July 2016 when it was changed to “Face Material: 6-4 Titanium”. Is it likely that the SP700 face was changed at the same time the longer hosel… Read more »

James To the best of my recollection, the SP700 material was changed to 6/4 in 2016. That was when we changed the factory for the 919 and the new one did not source the SP700 and had no interest in doing so. Which really didn’t matter because COR is COR no matter if the face is SP700, 6/4, 15-3-3-3, 10-2-3 or whatever the titanium alloy. So if the head was 0.825 for the SP700 and 0.825 for the 6/4, it doesn’t have any bearing on the performance or ball speed or whatever. The reason everyone eventually went away from beta… Read more »

Hi Tom, I’m looking to put my 919 back into play after a while not using it (sorry!!) due to me accidentally breaking the shaft while taking my clubs out the car. It originally had the S2S Black in 85g but since then I’ve had some back issues so reckon the 85g may be a bit heavy for me now. I’ve been using a 60g Kuro Kage shaft in my spare TM driver (which I really like). . What I’d like to know is, do I just go straight to the 65g S2S Black or is there something closer to… Read more »

Hi Tom, Has there ever been a comparison by anyone of the 919THI to the latest and greatest from the big name brands? Wondering how a custom fit 919THI would stack up on the Trackman or GC quad launch monitors vs the new Calloway Paradym, Taylormade Stealth, Ping G430 or Cobra Aerojet etc.? Any chance anyone could do a club review on the new 719MV? I remember watching a Rick Shiels video a couple years ago do a review of the Sterling Irons. He seemed pretty impressed but didn’t like the lower ball flight of the 4 and 5 iron.… Read more »

DAVE I have done a little hitting comparison between the 919 and other brand drivers but never published the data because I have always known that comparison test data from a golf company is always viewed suspiciously to be biased. The best way I can tell you to get a far less biased comparison between any of my head designs and any other golf clubs is to talk to or ask any of the long time professional clubmakers what they have seen in their countless actual fittings with golfers in their respective areas. Almost every one of these clubmakers offer… Read more »

Thanks for the great reply Tom. I’ll definitely go to AGCP to see what feedback they can provide. Love your clubs! Just wanted to be able to point guys looking for new clubs in a direction where they can see the data supporting the benefits of the performance the Wishon line provides in comparison to what’s out there.

Thanks again!

Dave

Dave Unlike with every other golf equipment company that simply creates their new club models to only be built to one series of standard specs so they can be more easily sold off the rack in volume, our models are only sold as components to be used by independent custom clubmakers to CUSTOM FIT each golfer. So many golfers have no idea what real fitting done by an independent professional is compared to the BS crap that retailers claim to offer as fitting when people walk into a retail golf store. Real fitting is customizing all 12 of the key… Read more »

Hi Tom What I expected you to say was something along these lines. I wonder if what I’m about to say is valid? There are a finite number of factors that can affect how far a driver can hit the ball, if you are talking about the head itself. These are spring effect (CoR), how much it twists (moi) and head volume (cc). Possibly also off centre hit forgiveness Since about 2006 there have been limits on these elements and all drivers made since around or soon after this time are as close to these limits as you can realistically… Read more »

Frazer I am sorry I should have better qualified that statement I made about loft and distance in my post to the man thinking about bending the lofts of the 771 set to be the same as the lofts of his current set. Sorry about that confusion. Yes, for sure, COR has a big role to play in ball speed and distance. I left that out because I was just assuming an apples to apples comparison between the iron sets for COR, being played by the same golfer. MOI only plays a role in distance for off center hits. I… Read more »

Hey Dave, I have a guy that likes to take his 919 into the shops to test against the latest releases, his club has better ball speeds than most, never beaten, matched occasionally. His latest report was “919THI beats TSR3” I get that kind of feedback often.

That’s so cool to hear Tom! Would love to get his data of the clubs he’s compared his 919THI with, especially if he has data compared to the Paradym or Stealth etc…I absolutely love the 919, so much so I had my friend and clubmaker build me another one after my original that I absolutely used and abused for 3+ years finally suffered a crack. Hate to think how many hits I had on that thing considering how much I play and also hit it on the range. I’m looking forward to enjoying many more rounds with my new beloved… Read more »

Tom the folks At Diamond International and I am sure you have just released fantastic pictures and specs of the new 719MW Driver. I have a few questions for the head. Obviously adjustable on the hosel and a weighting system to help the draw, the fade, and center of gravity either rearward or forward. Your adjustable sleeve .. Will you have your own mechanism or will you use an adaptation of let’s say a Taylormade type or something like the Titleist? What will the head weight for the 719MW be before adding the weights? (raw weight 173 grams or so?)… Read more »

ROG Thanks for your kind comments and enthusiasm about the new 719MW driver. It’s been a LONG LONG time in development. Being able to investment cast the titanium body light enough with proper strength was a huge challenge, so we could incorporate as much as a 30g weight in the head to be able to make a visible difference in shot shape. It is so difficult to cast titanium very thin with proper strength, because molten titanium has the viscosity of molasses. It took some real casting breakthroughs to get the molten Ti to flow and fill every nook and… Read more »

Tom first I want to thank you for your detailed answer. I will buy this driver, but I would also point out that the 919THI Driver with a bendable hosel plus the fact that you can hand select for loft still makes this a more than viable option. I am looking forward to the new wedges. Thanks Tom, Merry Christmas and a healthy New Year!

Hi Tom, After much use and abuse, my much loved 9 degree THI has finally given up. I was hitting bombs at the driving range today when the lovely sound changed. After a few more hits and duds, upon inspection, there was a crack running from the middle of the face right to one the lines on the sole of the club ill be happy to share pics if you email me. My replacement is going to be another THI. I’ve tried newer drivers over the years but always come back to using the THI. Thanks for making a great… Read more »

NIK Just like with us humans, there is a life expectancy for driver heads. Thankfully ours is a lot longer than a driver head (!!) but still, that means you must have had several thousand hits with it before it decided it was time to retire! I really do have to say it has been very satisfying to have created the 919 because face performance wise, I just think it’s almost impossible to make a driver better. Then when I had the chance to tweak it with the bendable hosel, it just went down in my book as a driver… Read more »

Hi Tom,

Would you have any suggestions on how one could obtain this clubhead? I live in Canada and frequently visit the United States.

I am a short individual with long arms. Thus I play my clubs very flat (5 iron@ 55.5 Degrees).

This is the first Driver that I’ve seen that is capable of being bent to 54 degrees flat.

Marc Thanks very much for your interest. I can tell from your question that you are not familar with our company and how we do business so please allow me to explain so everything is clear. We sell our designs as component heads, shafts, grips only to approved, qualified custom clubmakers around the world, who then fit and custom build the components into finished custom made clubs for end user golfers. We do not sell our components to golfers who are not qualified clubmakers because if we did that, we would have no way to police the quality of the… Read more »